What is shaped steel, shaped rolled steel processing?

Shaped steel is a type of steel produced in many types of tools such as U-shaped, H-shaped, I-shaped, L-shaped, and many other shapes depending on the needs of use.

This shape is created from the heating or conditioning information of the head steel plates. Sectional steel is often used in construction and industry to create profiles and frame columns, contributing to increasing mechanical properties and material loading capacity

Application of shaped steel

Shaped steel has many wide applications in many different fields. Below are some common applications of shaped steel:

- Construction: Sectional steel is widely used in the construction industry to create structures and column frames for buildings, bridges, industrial factories and other construction projects. Shapes such as I-beam, H-beam and U-beam steel are often used to provide stability and load-bearing for these structures.

- Mechanical processing: In the mechanical industry, shaped steel is used to create machine parts, structural frames for industrial machines, and other products in this field.

- Energy Fabrication: In the energy industry, steel sections are used in the construction and protection of energy facilities such as power plants, nuclear plants, and energy-related facilities.

- Ships: In the shipbuilding industry, shaped steel is also used to build ship hulls, seaports and structures related to the transportation of goods at sea

- Medical equipment: In some medical applications, shaped steel can be used in the construction of hospitals and other medical facilities, as well as in the production and processing of medical equipment that requires durability. and high load capacity.

- Furniture: Shaped steel can also be used in the furniture manufacturing industry to create interior products such as tables, chairs, shelves and other interior decorations.

In addition, shaped steel is also used in many other fields depending on specific requirements.

Process of processing shaped rolled steel.

- Step 1: Receive customer requests (Design drawings, technical requirements).

- Step 2: Specialized design software.

- Step 3: Export data (Drawings, material BOM, machine operating data)

- Step 4: Production of rolled steel bars

- Step 5: Packaging and delivery

All types of shaped steel are processed at Viet Son.

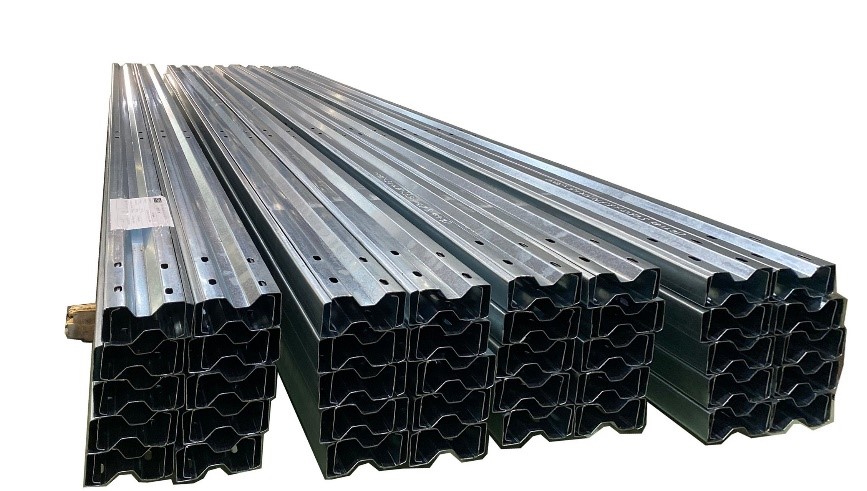

Sigma purlin

- Sigma purlins are rolled with tendons in the middle of the abdomen, helping to increase bearing capacity and stability by up to 15% compared to conventional C purlins.

- Sigma sections are often used as factory trusses; column frames, trusses for warehouses, crane-less factories, etc.

C Purlin

- C purlins have two equal wings, are easy to disassemble, easy to transport, light in weight, and have good bearing capacity.

- C purlins are used as trusses and wall frames; Column frames for simple constructions; Usually used in projects with column pitch less than 6m

Z purlin

- The cross section of Z purlin has two unequal wings, which is convenient for supporting joints, thereby increasing the cross section at the support, where the bending moment and shear moment are the largest, helping the Z purlin increase its load-bearing capacity.

- Z purlins help with easy packaging, convenient transportation and quick installation.

- Z purlin is the solution for roof purlins, wall purlins,…

Omega purlin

- Omega purlins have an A-shaped cross section so they can be connected against each other, thereby increasing the cross-section at the support, where the bending moment and shear moment are the largest; Helps the Omega bar increase its load-bearing capacity. The A-shaped section helps increase the stability of the frame system.

Thanks to the ability to overlap, Omega purlins are easy to pack and transport.

Omega purlins are solutions for roof purlins, solar battery support systems,…

Truss Bar C

- The C truss bar has two unequal wings that are convenient for interlocking to increase stiffness and stability.

- C truss bars are used as truss frames; interior partition frames, walls.

U Truss Bar

- The U truss bar does not have a handle, it is easy to interlock, connect with the C truss bar to form a frame or reinforce the C truss at locations with high stress.

- U truss bars are often combined with C truss bars to make frames for interior partitions and walls. Thanks to the U cross section, they are easily packaged and conveniently transported.

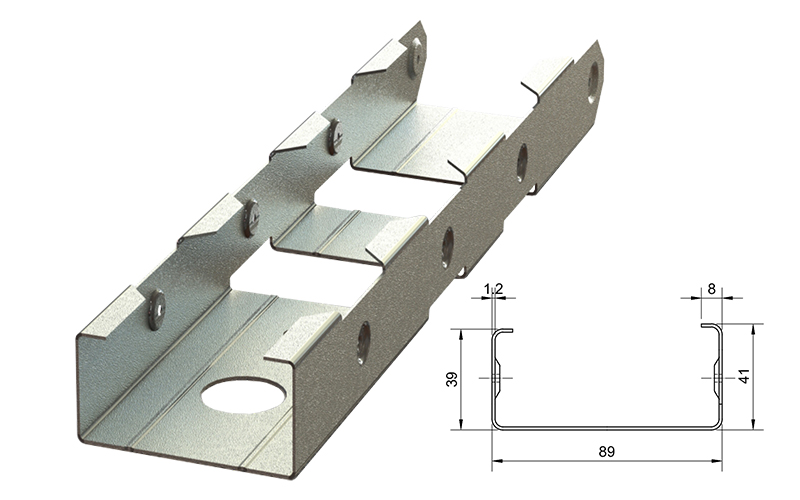

Bar U41/U21

- U41/U21 bars are pre-punched for quick construction, easy to assemble bolts, without using welds. The bar is rolled with two whiskers to help increase stability, increase load-bearing capacity, and make the system sturdy.

- U41/U21 bars are often used as electromechanical supports, combined with threaded rods to hang cable tray systems

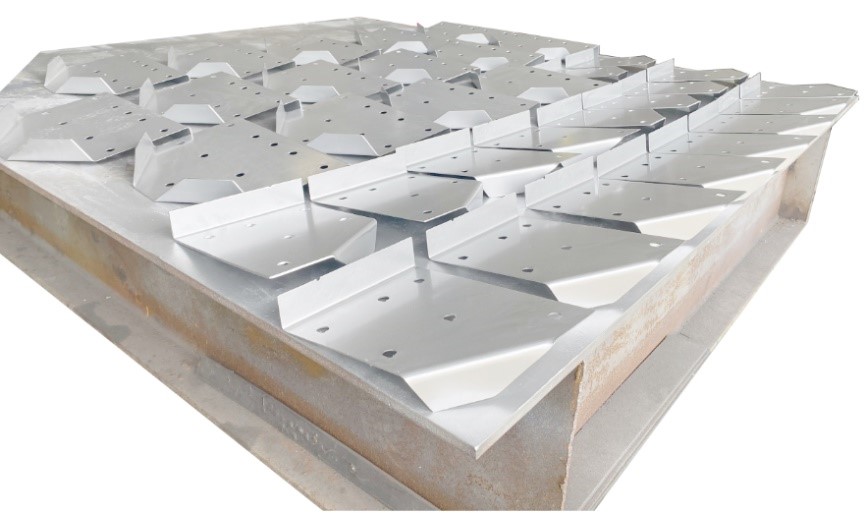

Working plate floor

The working floor plate can be rolled with friction ribs, helping the construction worker easily switch on the floor plate without slipping. The floor panels are convenient for disassembly and installation, and have drainage holes to always keep the floor panels dry

Cable tray

- Máng cáp được có hai râu bằng nhau giúp tăng độ cứng vững, đồng thời tăng khả năng chịu tải, chứa được nhiều cáp điện hơn. Hệ thống lỗ đột ở bụng thuận lợi cho việc lắp đặt, kiểm tra cáp điện. Ngoài ra còn có các phụ kiện giúp thi công dễ dàng, đẹp.

- Máng cáp và các phụ kiện đi kèm được dùng trong các công trình cáp điện mặt trời, hệ thống điện trong các nhà máy công nghiệp,…

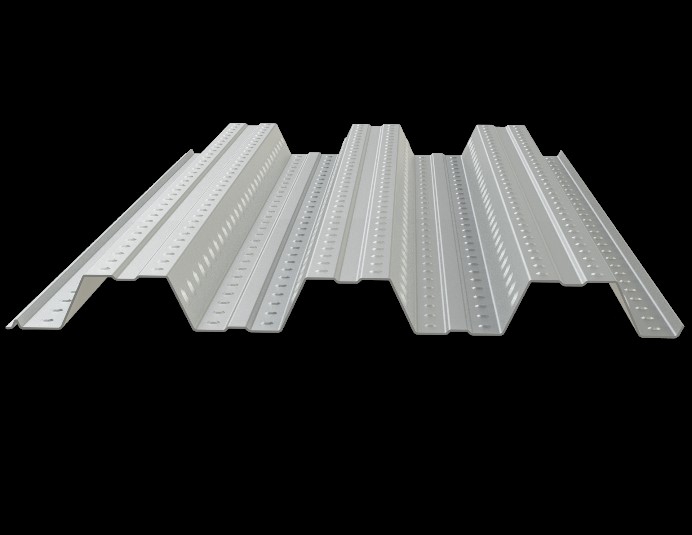

Floor panels

Floor plate FD600-H75:

Effective width: 600mm

Height: 75mm

Step: 200mm

Floor plate FD930-H50:

Effective width: 930mm

Height: 50mm;

Step: 232mm

Floor plate FD900-H75:

Effective width: 900mm

Height: 75mm;

Step: 200mm

Floor plate FD1000-H50

Effective width: 1000mm

Height: 50mm; Step: 333mm

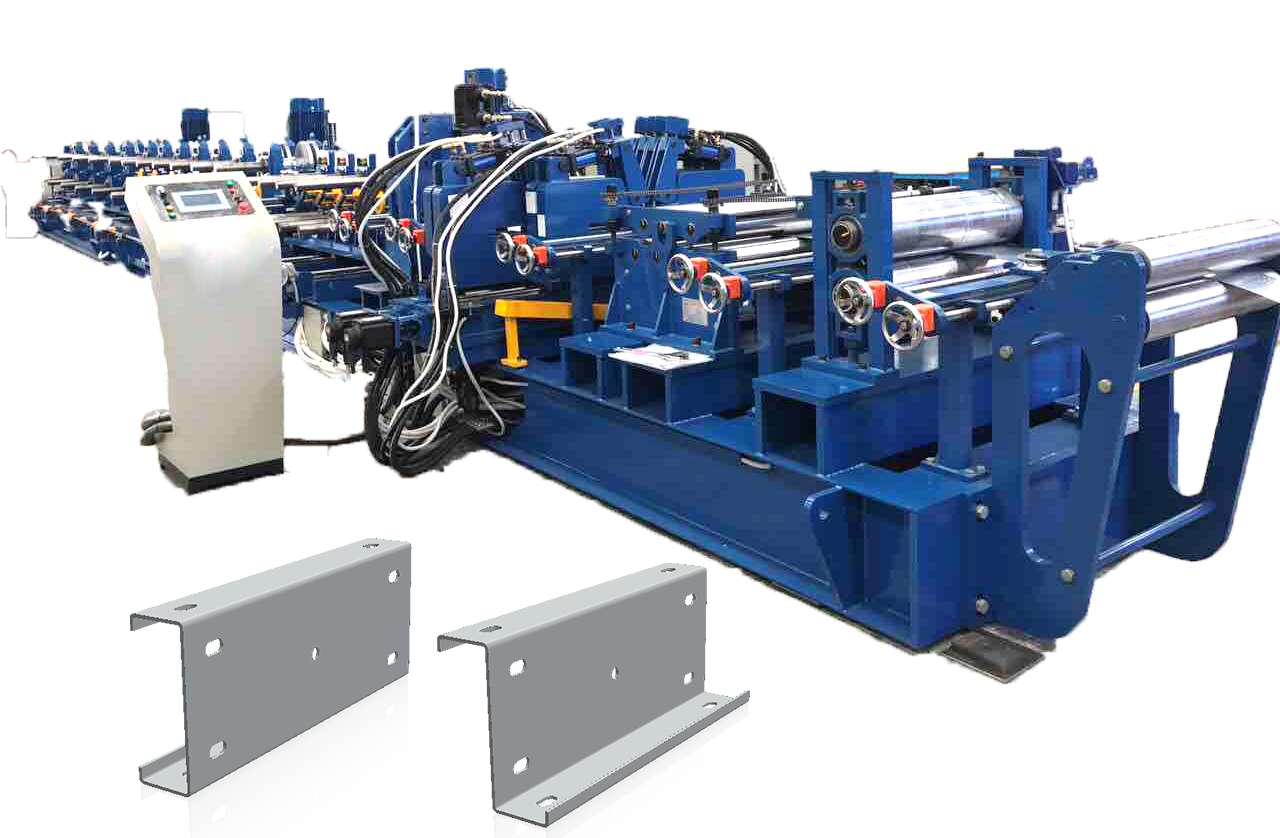

Steel processing machinery at Viet Son Mechanical

Smartframe machine

- Automatic rolling and punching technology according to CNC data from specialized software.

- All house frame components are flexibly produced on a single rolling machine.

Sigma beam rolling machine

- Tự động cán, cắt, đột lỗ theo kích thước và vị trí được thiết lập trong hệ thống điều khiển.

- Kích thước biên dạng được điều chỉnh tự động.

Omega rolling machine

Automatically roll, cut, and punch holes according to the position set in the control system

Máy cán thanh C/Z

Tự động cán, cắt, đột lỗ theo vị trí được thiết lập trong hệ thống điều khiển.

Floor slab rolling machine

Automatically roll and cut according to the size set in the control system.

Laser cutting machine

Cut sheet metal quickly and accurately

Shock machine

Bending sheet metal products such as panels and auxiliary components.

Quotation for processing rolled shaped steel

The unit price for processing shaped rolled steel depends on the following factors:

Order volume: The amount of rolled steel that needs to be processed will greatly affect the final price. Often, ordering large quantities can result in a lower unit price per product.

Technical requirements and standards: If there are specific technical or standard requirements for the product, for example, exact dimensions, toughness, hardness, durability, or surface requirements, then the This request will affect the final price. More complex machining jobs may require special techniques and equipment, increasing the unit price.

Required schedule: If delivery is needed quickly or according to a specific schedule, it will depend on working time and resources to complete the order. If overtime or holiday work is required, this may also impact the final price.

To get a specific quote, you can send a specific request to Viet Son Mechanical for support.

Why should you process shaped steel at Viet Son Mechanical?

Viet Son Mechanical is a reputable and quality shaped steel processing unit for the following reasons:

Modern machinery and equipment: Viet Son Mechanical is equipped with modern machinery and equipment to perform shaped steel processing effectively and with quality. This can ensure that the final product meets specific technical requirements and standards.

High precision: Using advanced machinery and technology, Viet Son Mechanical has the ability to work with high precision, helping the final product have accurate dimensions and characteristics.

Meet large output: Viet Son Mechanical has the ability to meet large output, this is especially important if you have a large order or need to mass produce products.

Fully certified materials: Viet Son Mechanical is capable of providing quality certified steel materials, ensuring that your products comply with safety and quality standards.

Guaranteed on schedule: Viet Son Mechanical can commit to the project’s schedule and ensure that your order will be completed on time, which is especially important in construction and industrial production. .

Prestige and quality: Viet Son Mechanical has a reputation in the metal and steel processing industry, and they are recognized for the quality of their products and services.

Above is information about shaped rolled steel processing of Viet Son Mechanical. If you have a need for processing or need to find a unit price for processing shaped steel, please contact Viet Son immediately via the hotline number for support!