In the current fiercely competitive context, optimizing production and transportation processes is an important factor determining the success of a business. Understanding that, Viet Son Mechanical Company Limited is proud to introduce to customers the automatic container system – the perfect solution to help improve efficiency, reduce costs and ensure the quality of goods.

Why should you choose Viet Son’s automatic container system?

- Modern technology: The system is equipped with the most advanced technology, ensuring stable and accurate operation.

- Superior quality: Products are manufactured on modern production lines, from high-quality materials, ensuring quality and durability.

- Professional technical team: Viet Son owns a team of experienced engineers, ready to support customers 24/7.

- Attentive after-sales service: We are committed to providing professional warranty and maintenance services, ensuring customer satisfaction.

Outstanding benefits

- Improve productivity: Automate the packaging process, reduce time and labor, helping businesses increase productivity

- Reduce costs: Save labor costs, minimize the risk of damage to goods, optimize transportation costs.

- Protect goods: Ensure goods are neatly and safely arranged, minimizing damage during transportation.

- Optimize space: Arrange goods optimally, maximize container space, help save transportation costs.

- Environmentally friendly: Minimize packaging waste, contribute to environmental protection.

- Flexible: Easily customized to suit many types of goods and different container sizes.

- Safe and efficient: Avoid causing unnecessary accidents during the process of arranging goods compared to normal arrangement.

How does the system work?

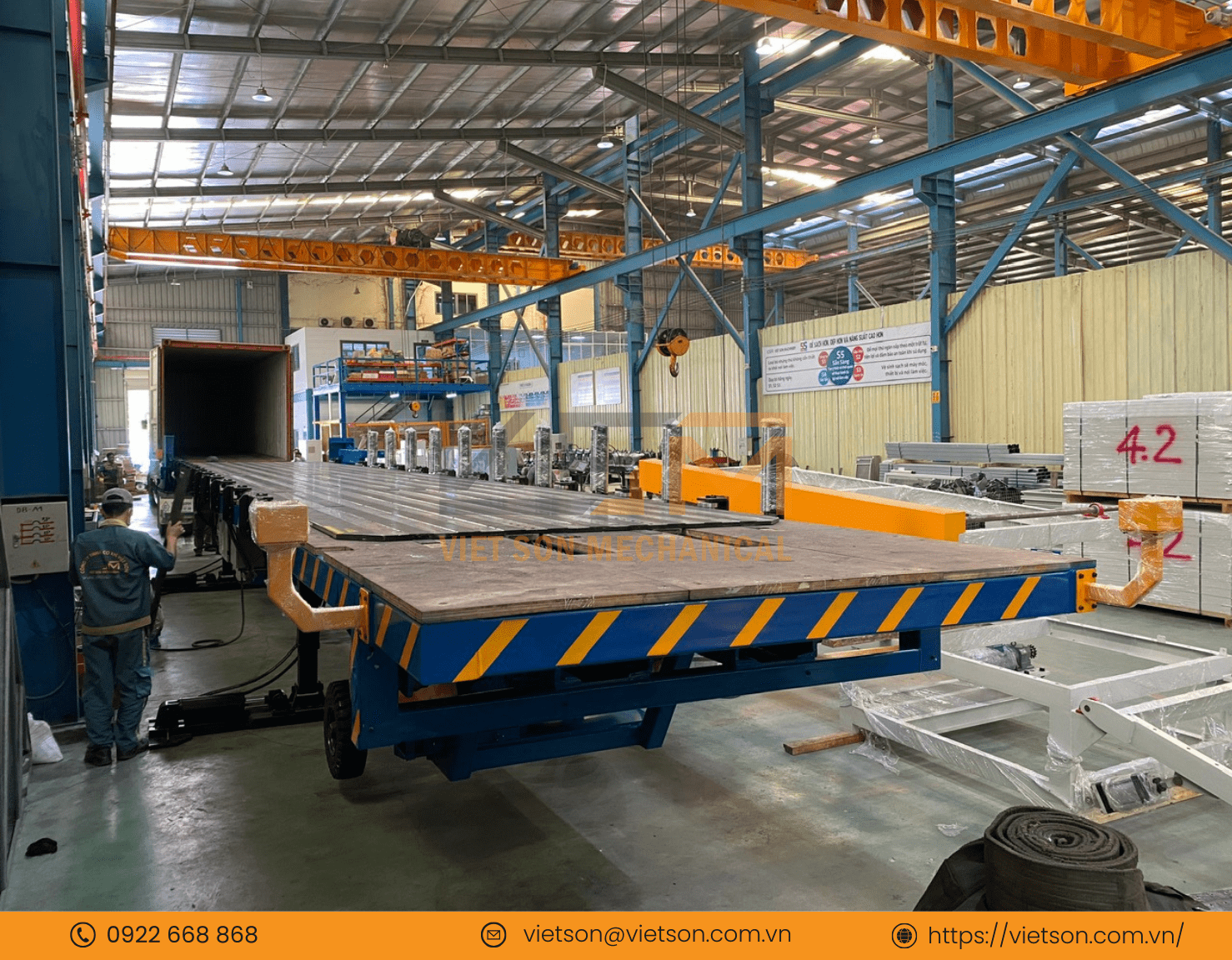

The machine operates in a sequential process of the following steps:

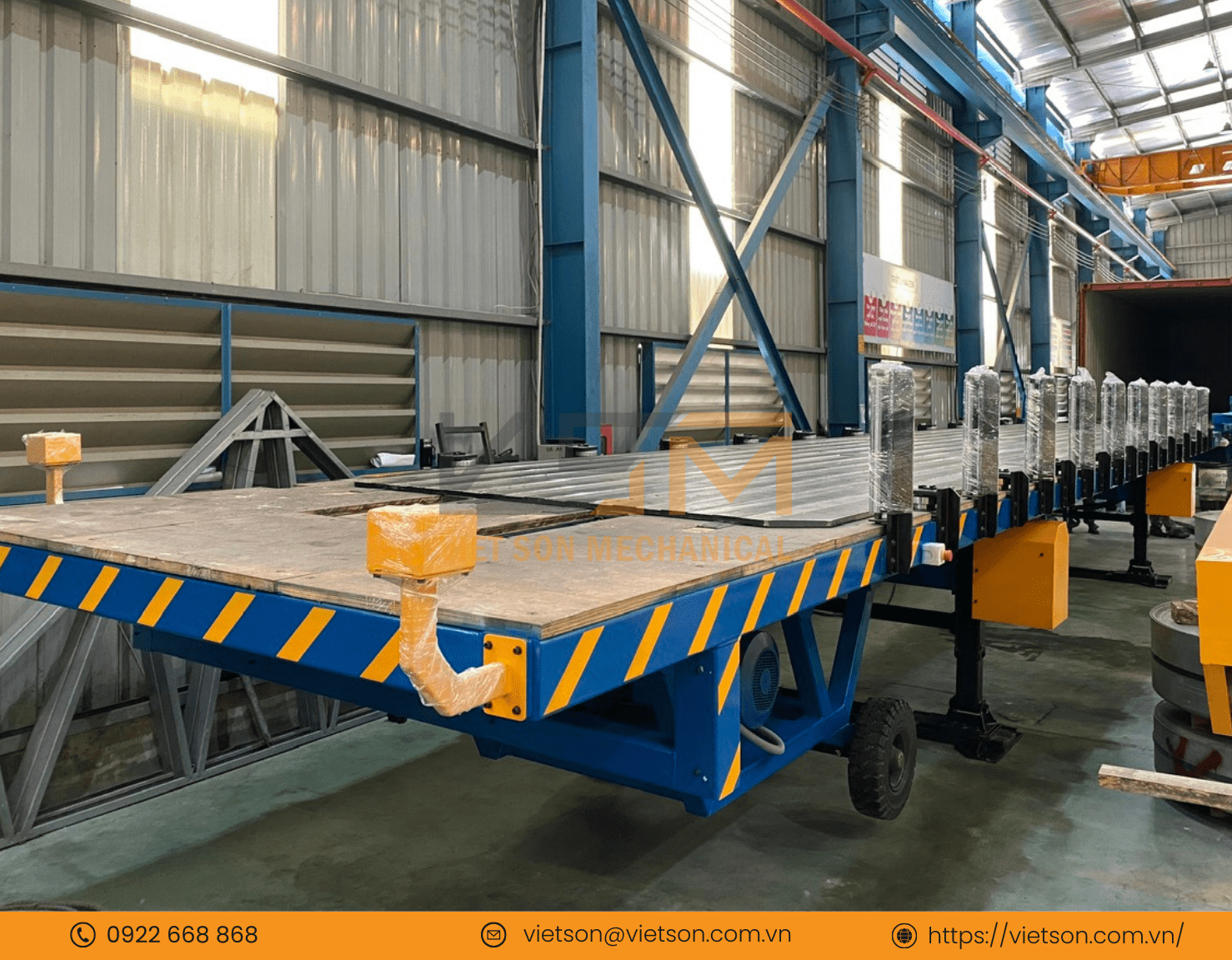

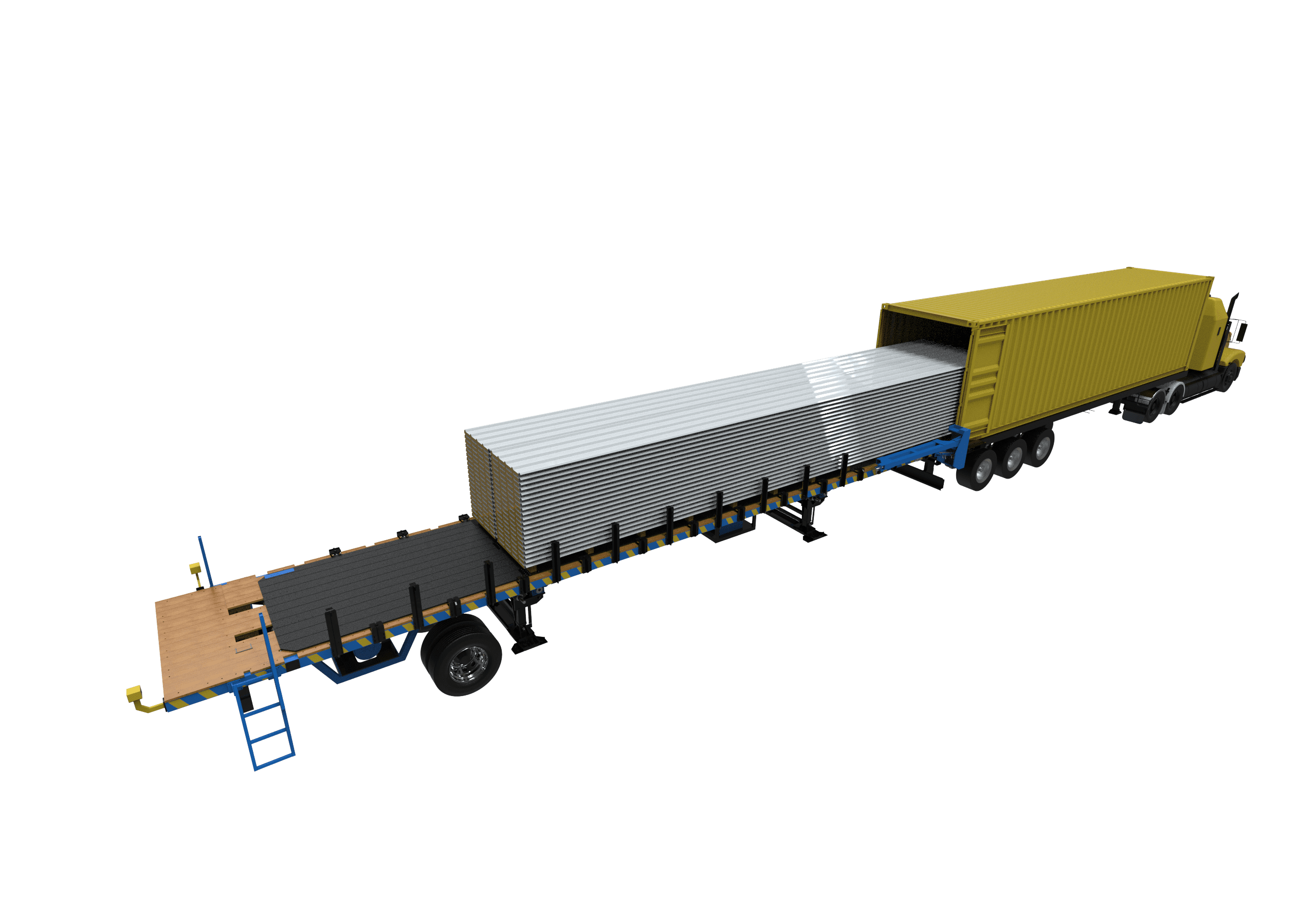

- Palletize goods on the loading table: Prepared pallets of goods will be placed on the machine’s loading table. This loading table usually has the ability to lift and lower to adjust the height to suit the container.

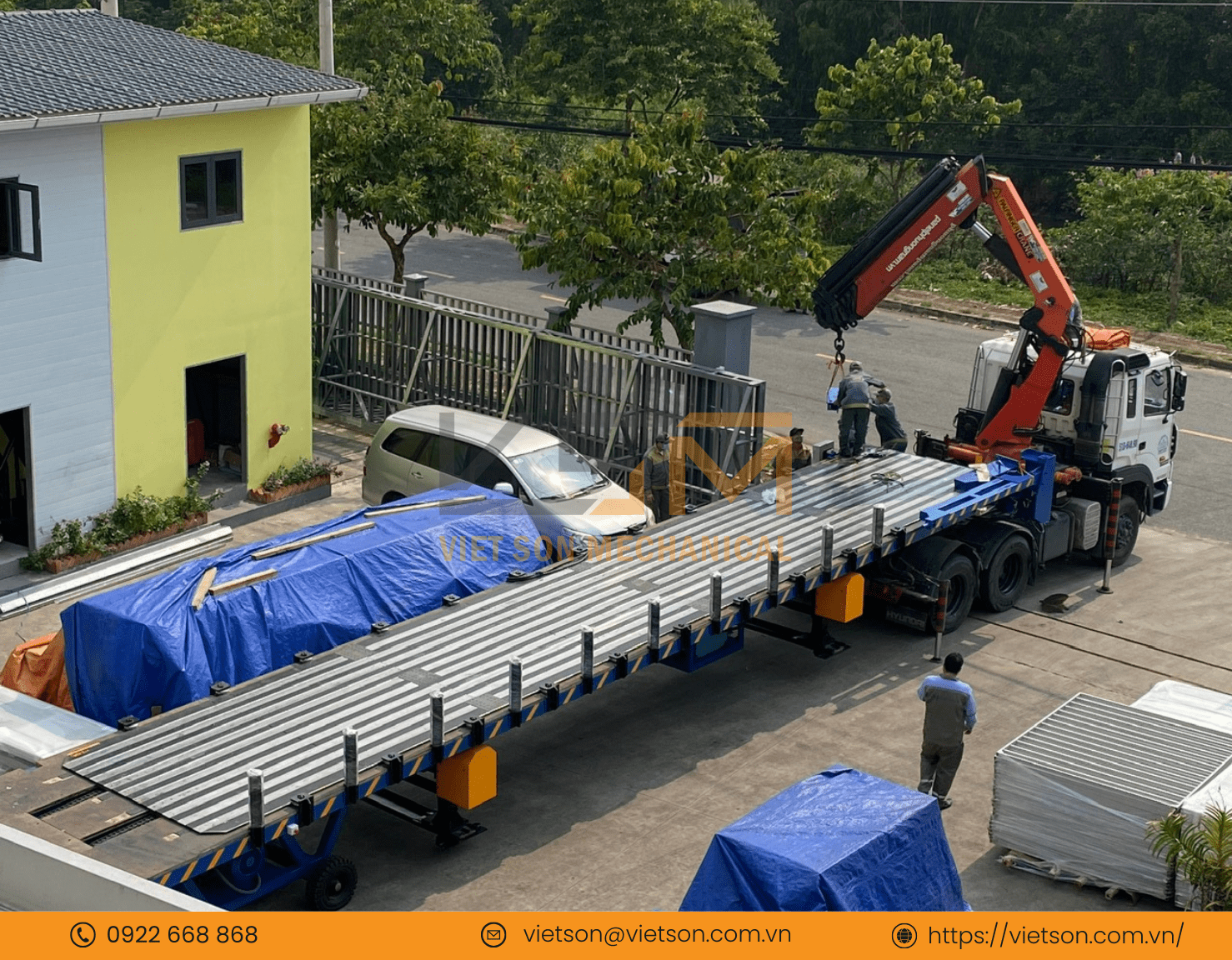

- Container connection: The container will be pulled to and connected to the machine. This connection ensures stability and tightness between the container and the machine during operation.

- Setting parameters and pushing the loading table into the container: The operator will enter the necessary parameters into the control system such as container size, cargo weight. Then, the loading table will be pushed inside the container along a predetermined rail.

- Closing the cargo barrier door: When the loading table is in the correct position, the cargo barrier door will automatically close to secure the goods inside the container.

- Removing the loading table: After closing the door, the loading table will be pulled out of the container to prepare for the next loading.

- Removing the container fixing clamp: Finally, the container fixing clamps will be removed, completing the loading process.

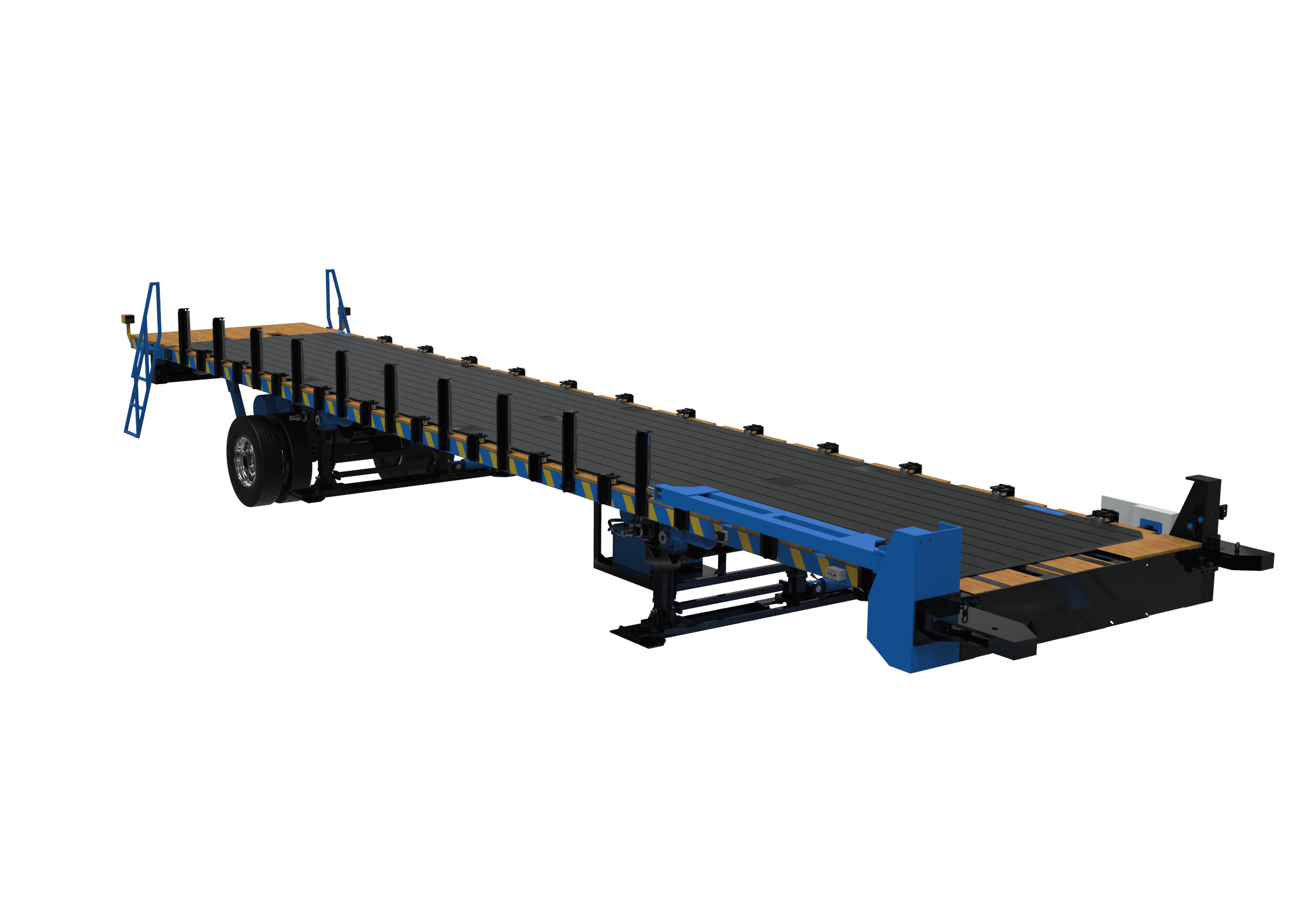

Simulation image

The entire process is controlled by an automatic system, which helps to minimize human intervention, increase productivity and ensure high accuracy.

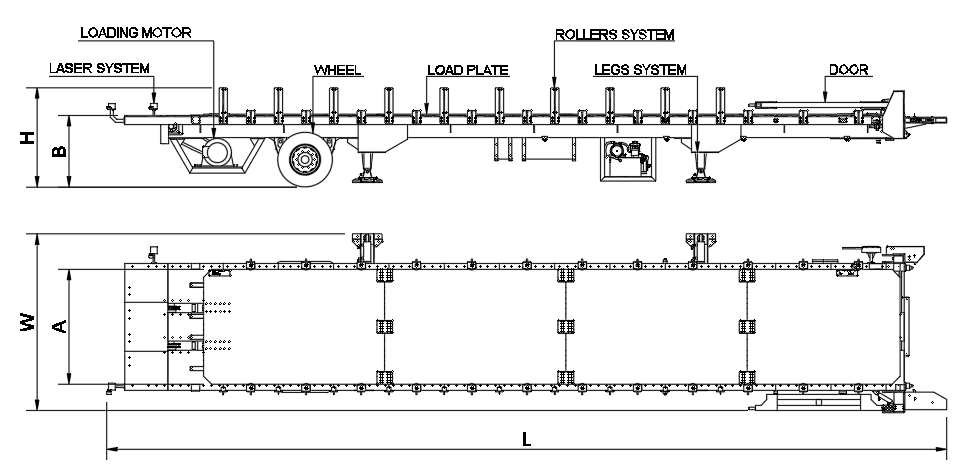

Technical parameters

| HẠNG MỤC

ITEMS |

THÔNG SỐ KỸ THUẬT

TECHNICAL DATA |

|

| Kích thước

Dimensions |

LxWxH | 16.2m x 3.4m x 2.1m |

| Chiều cao bàn tải (B) – Loading plate height | 1.45-1.7m | |

| Chiều rộng bàn tải (A) – Loading plate width | 2.2m | |

| Khối lượng máy – System’s weight | 17 tấn-tons | |

| Công suất – Power | ~30 kW | |

| Tải trọng hàng hóa – Cargo load | 25 tấn-tons | |

| Tốc độ bàn tải – Loading plate speed | 5 mét/phút – meters/minutes | |

Container packing machine system simulation drawing

Why choose Viet Son?

- Experience: With many years of experience in the field of machinery and equipment manufacturing, Viet Son has affirmed its position in the market.

- Quality: Viet Son’s products are manufactured on modern production lines, meeting international quality standards.

- Service: We are committed to providing professional consulting, installation and maintenance services, ensuring customer satisfaction.

- Competitive price: We always offer the most reasonable and competitive prices on the market.

Do you want to improve production and business efficiency? Contact us now for advice and experience Viet Son’s automatic container packing system.

► Contact for Machining: 0922 668 868 (Zalo – Viber – WhatsApp)

► Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

► Website: https://vietson.com.vn/

► Email: [email protected]

► Facebook: https://www.facebook.com/cokhivietson

► Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w