I. Introduction

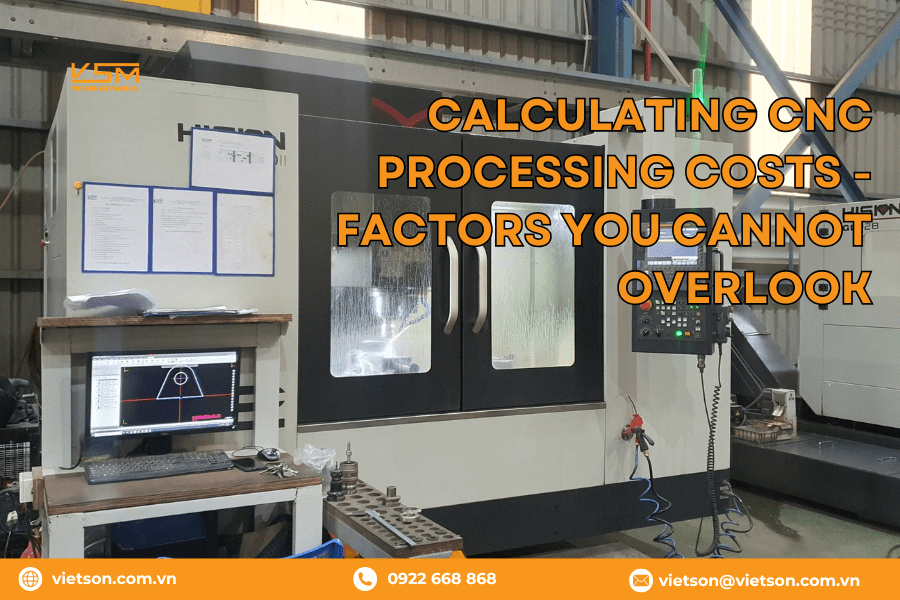

1.What is CNC machining? Why is cost calculation important?

CNC machining (Computer Numerical Control) is a modern mechanical processing method, in which the cutting and shaping of materials are carried out entirely automatically thanks to computer-controlled machinery..

Why is CNC machining costs calculation important?

- Budget control and production cost optimization

- Reasonable product pricing

- Reduce waste and improve production efficiency

- Improving competitiveness in the market

- Increase profits and ensure sustainable development

- Support making accurate investment decisions

- Minimize financial risk

2. The benefits of optimizing CNC machining costs for businesses

- Reduce production costs, increase profits

- Compete better in the market

- Optimize the production process and improve efficiency

- Reduce machinery wear and extend equipment lifespan

- Improve cash flow and better financial management

- Increase the reliability and quality of the product

II. Factors affecting CNC machining costs

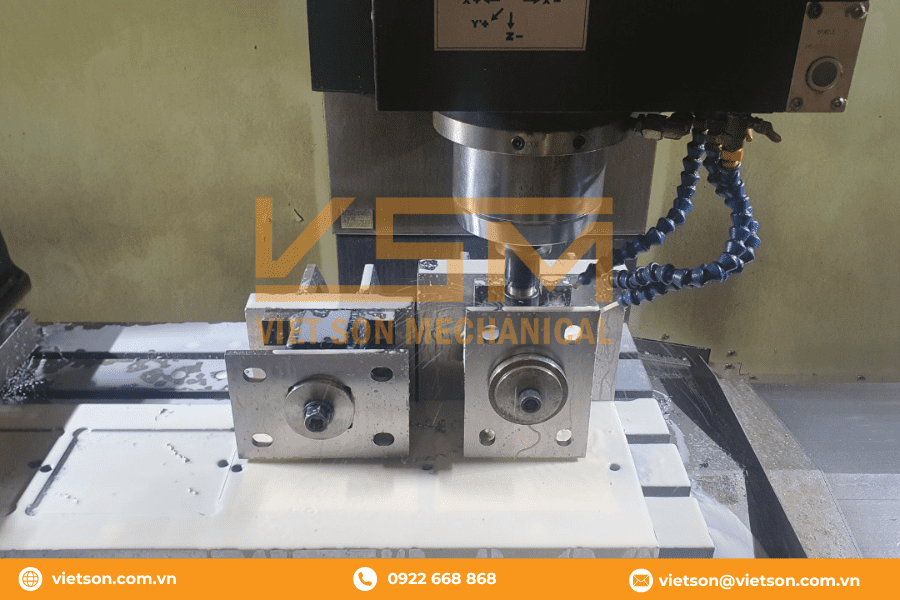

1. Design a part and complexity

First, you need to consider how complex the part to be created will be. Indeed, the design of the part and its geometry can play a significant role in machining costs.

The more complex a component is, the more expensive its production becomes. This is due to various factors such as the need for more advanced machinery, the manufacturing time for each part, the potential need for multiple setups and processes, as well as the need for stricter quality control due to tight tolerances.

Non-standard parts with thin walls, deep holes, uneven dimensions, or high surface quality can also lead to higher manufacturing costs per part.

2. Production volume

This is one of the most commonly understood factors in manufacturing costs. The larger the volume of the produced parts, the lower the price per part.

A major challenge here is the shift towards high-mix low-volume production, which forces machine shops to create many different types of products in small batches. Such practices will certainly increase the processing costs.

3.Type of material

Different materials have different costs. A standard block of stainless steel will certainly be cheaper than a higher-end alloy like Inconel on a per-block basis.

Some standard materials used in machining include Aluminum, Stainless Steel, Brass, or even Titanium alloys. Depending on the chosen material, you will experience different levels of machining and costs.

4. Costs related to CNC machines

- The cost of the machine tool itself

- Estimated annual cost for spare parts (reflecting the quality manufactured/used in that machine)

- Estimated number of hours the machine can operate in a year

- Labor costs necessary to operate the machine

- The types of cutting tools you can use with your machine

- Surface finishing can be achieved.

- The availability of automation systems (find out how Hwacheon does it here)

- The ability of the machine to pass through multiple axes

- The time required to set up, manage, and post-process the components

- Necessary maintenance and repair costs (learn how to apply preventive maintenance here)

5.Programming Costs

Programming is often expensive because it requires specialized personnel to design and digitize the necessary parts, as well as the required level of CAD/CAM.

First, the product needs to be handed over to a designer who has created a CAD file (Computer-Aided Design). Next, the manufacturing engineer needs to check whether the design can be produced efficiently and make suggestions to improve its machinability. Finally, a programmer is required to convert the CAD files into CAM files, which will then be fed into the CNC machine.

6. Setup, conversion, and processing costs

Setup costs are often associated with the manufacturing engineer, who will need to ensure that everything is ready before the first batch of parts can be produced. He will need to plan the production process, the necessary materials, set up the machine, as well as how to clamp the materials/parts and accommodate any necessary changes (if any) and post-process the CAD file with a CAM.

7. Cost Quality

Also known as Cost of Quality (COQ), it is more accurately understood as the cost of poor quality. The cost of quality is associated with preventing, detecting, and resolving issues related to product quality.

In a manufacturing environment, those costs may include:

- The inspection cost necessary to evaluate a manufactured part for quality issues.

- Testing equipment is necessary to check the quality and consistency of the components.

- Internal error costs when defective products are produced – these products must be discarded or reworked.

- External failure costs occur when a defective product is delivered to the customer. These can be particularly costly if there is a product recall, warranty claims, field service, and even customer lawsuits!

8.Opportunity Cost

Opportunity costs can include any of the following costs:

- Downtime: The more downtime caused by interruptions in your production process, the more money you lose.

- Incident: Largely due to human error or equipment failure, and can even be as serious as a machine tool malfunction.

- Capacity: Depending on your production facility, you may not be able to take on additional work due to the capacity of your processing activities.

- Capacity: This could be another factor leading to missed opportunities and may include a lack of appropriate equipment or skilled personnel.

9. Utilities, space, labor, training, and other costs

Finally, it is necessary to consider the costs of electricity, water, waste disposal, cleaning, space, and other ongoing operational expenses. These can be significant if you are operating your machine shop 24/7.

Also, don’t forget the need to meet the changes in human resources, as well as the number of operators required for each process. Depending on the proficiency and skills of the workforce, it is also necessary to meet their training and skill enhancement needs.

III. Quotation for CNC machining service costs

The CNC machining cost table at Viet Son depends heavily on the machining time, the cost of input materials, and the technical requirements of the product.

OUTSOURCING SERVICES | Quotation |

CNC machining | Contact for a quote |

Machining mechanical parts | Contact for a quote |

Machining machine frames, machine parts, map tables, machining Base plates | Contact for a quote |

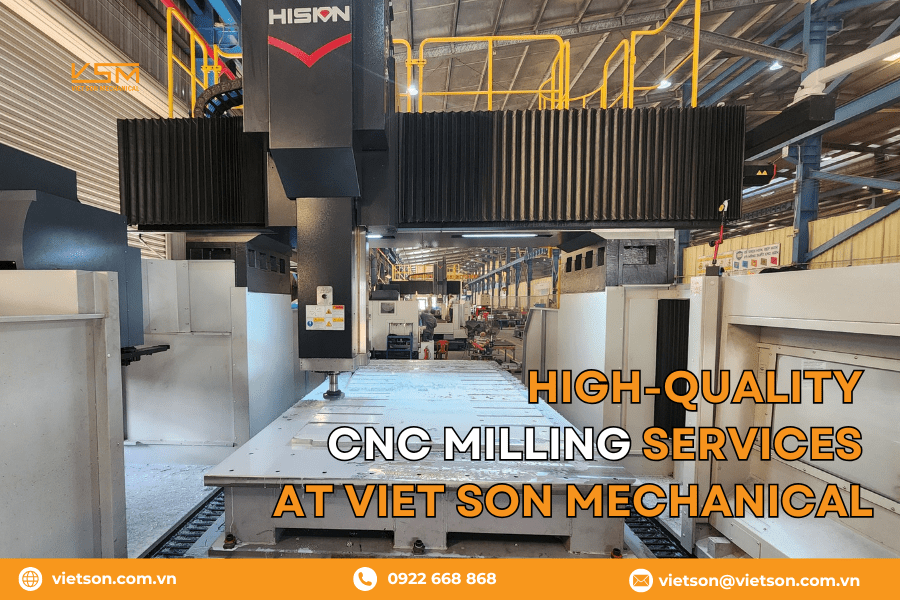

IV. CNC Machining at Viet Son Mechanical

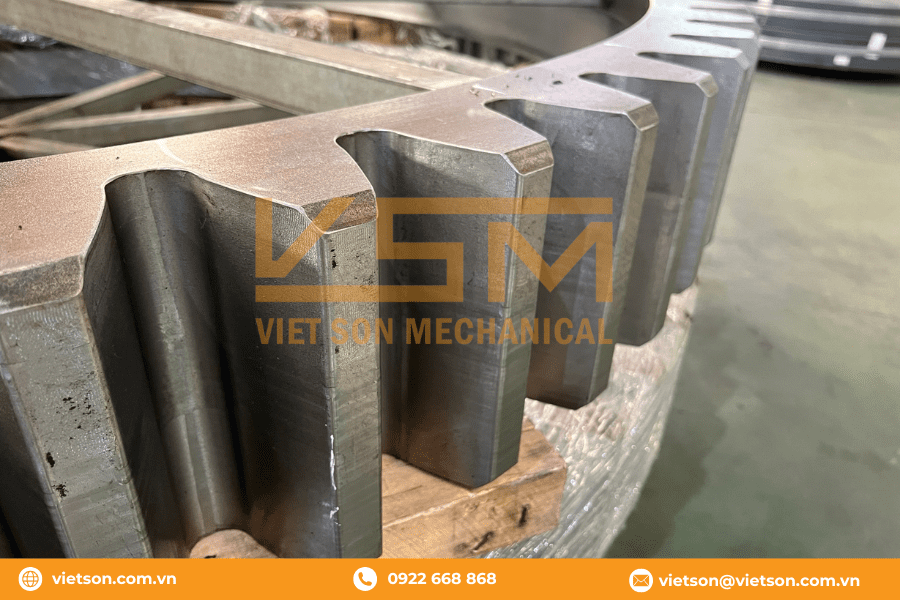

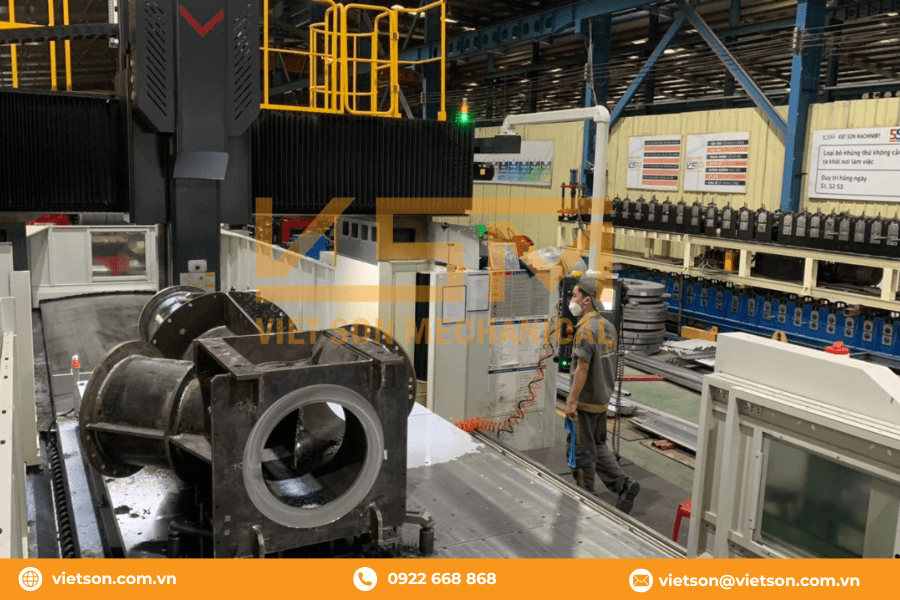

Viet Son Mechanical is one of the leading reputable enterprises in the field of CNC machining of machine parts in Vietnam. With over 10 years of experience in the industry, Viet Son Mechanical has established a solid position thanks to its highly skilled technicians and modern CNC machinery.

The company not only focuses on product quality but also emphasizes customer satisfaction, providing a variety of machining solutions, from milling, turning, to cutting and shaping machine parts.

With continuous efforts to improve and apply advanced technology, Viet Son Mechanical has become a trusted partner of many large and small enterprises across the country, contributing to enhanced production efficiency and meeting market demands.

V. Reasons to choose Viet Son Mechanical

Viet Son Mechanical began building its reputation from the early days of its establishment through the products created by the company and the credibility in its collaborations. And here are 4 reasons that have helped Việt Sơn maintain its reputation:

Possessing a highly capable workforce: with over 50 well-trained and experienced engineers in the mechanical industry, they can quickly and efficiently handle any issues or unexpected incidents that may arise.

Advanced operating equipment system: for Viet Son, to ensure the final product meets the required quality, a skilled team of technicians alone is not enough; it must be combined and supported by modern materials. Therefore, periodically, Việt Sơn always upgrades or purchases all the necessary equipment.

Extensive infrastructure: Speaking of this, it is certainly indispensable to mention the factory with over 11,000 m2 built solidly, with reasonably allocated areas that meet production needs.

Clear contract: all terms are carefully considered by Viet Son and included in the contract with the approval of both parties. The partner can base and compare after the product is completed for payment.

Contact to Order CNC Machining Services at Viet Son Mechanical

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website: https://vietson.com.vn/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w