The demand for lightweight steel frames is rapidly increasing due to their convenience, durability, and fast construction capabilities. To meet the need for producing high-quality purlins for various projects, the CZ Combination Purlin Machine emerges as an optimal solution. In this article, you will discover the technical specifications and outstanding applications of the CZ Combination Purlin Machine provided by Viet Son Mechanical.

..Introduction to the CZ Combination Purlin Machine

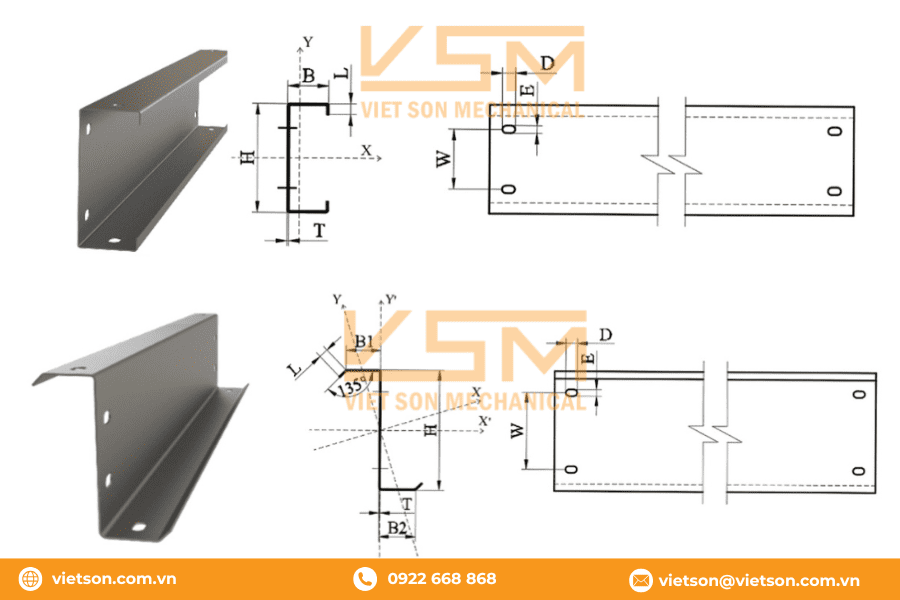

The CZ Combination Purlin Machine is an automated device designed to produce C and Z-shaped purlins – the two most popular types used in steel structure construction. Thanks to its smart design, the machine can change dimensions, form profiles, and switch between C and Z shapes within minutes.

Outstanding Advantages of the CZ Combination Purlin Machine

Superior Purlin Output Quality

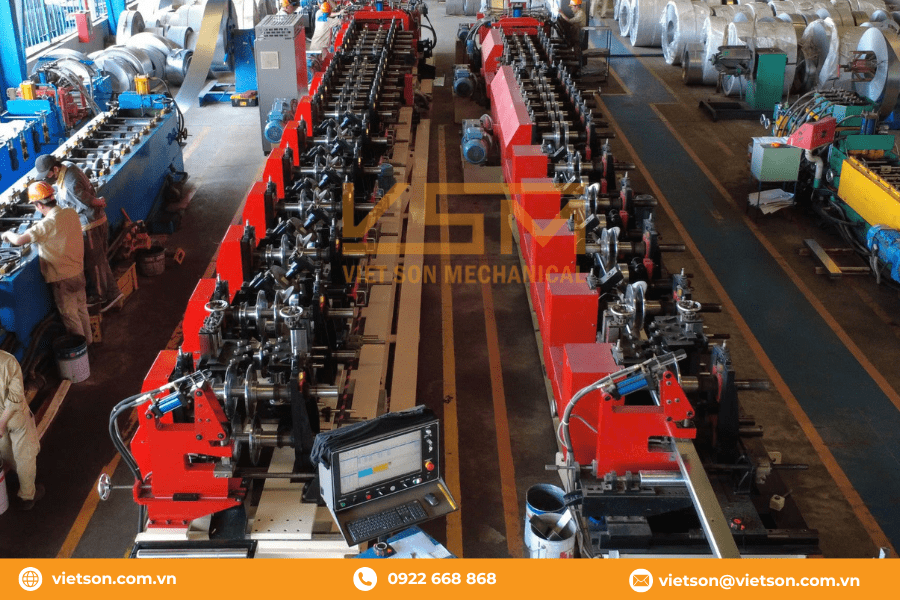

With precisely engineered rollers and a fully automatic continuous forming process, the CZ Combination Purlin Machine produces purlins with excellent straightness, sharp profiles, and no cracking, meeting the strictest construction standards.

Integrated Automatic Punching

Certain models of the CZ Combination Purlin Machine at Viet Son Mechanical are equipped with CNC punching systems, enabling hole punching during the forming process without additional machining steps. This shortens production time while ensuring absolute accuracy in hole positioning.

Easy Maintenance and Operation

The machine is user-friendly, with logically arranged components for easy operation and accessible critical parts for maintenance and replacement, optimizing long-term operational costs.

Customizable According to Customer Requirements

Viet Son Mechanical offers the flexibility to customize the CZ Combination Purlin Machine: adjusting size ranges, material thickness, and integrating additional functions such as automatic uncoiling and recoiling systems to suit various production scales.

Compliance with International Standards

All manufacturing and quality control processes at Viet Son Mechanical strictly adhere to ISO and international technical standards, ensuring the CZ Combination Purlin Machine is suitable for both domestic and export markets.

Applications of the CZ Combination Purlin Machine

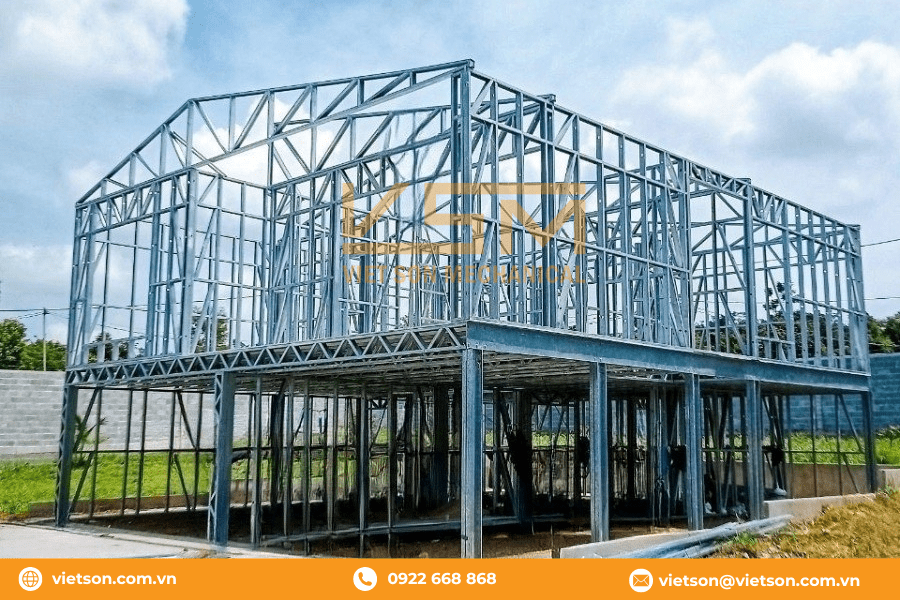

C and Z purlins produced by the CZ Combination Purlin Machine are widely used in multiple sectors, particularly in civil and industrial construction:

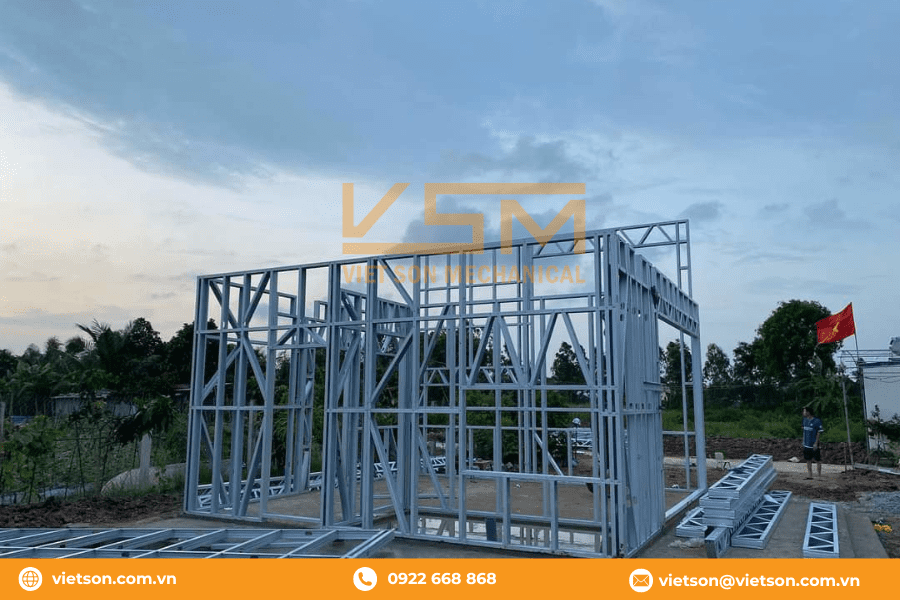

- Pre-engineered steel buildings: As the main structural elements in warehouses, factories, and steel buildings.

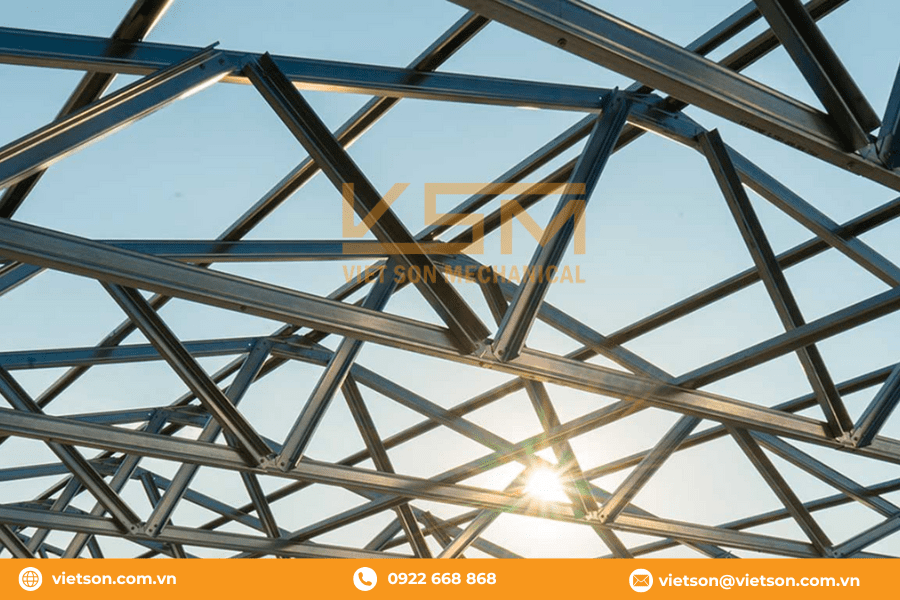

- Roofing and trusses: Serving as beams supporting roofing sheets or tiles in residential constructions.

- Load-bearing structures: Acting as secondary beams, trusses, or supporting components in bridges and plants.

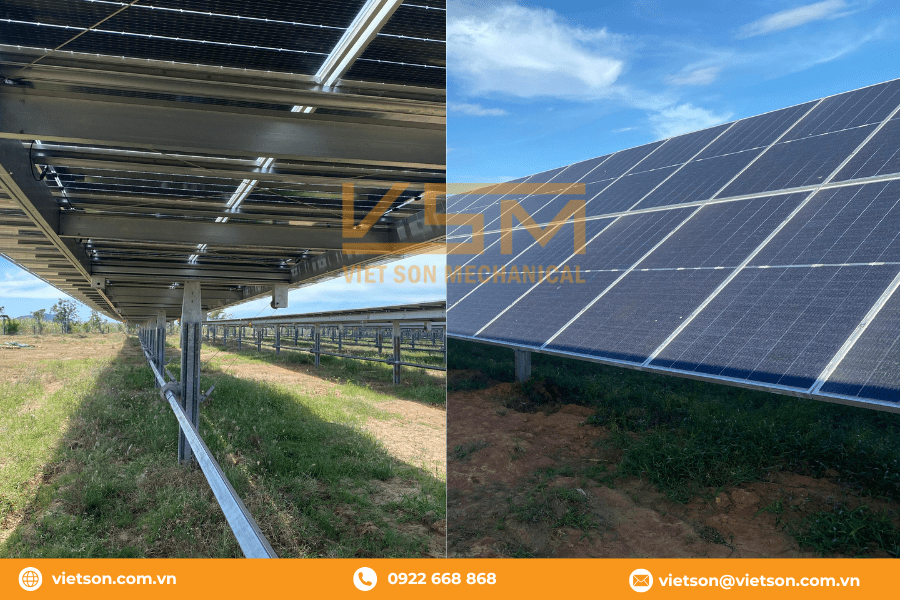

- Solar energy systems: Used as mounting structures for solar panels.

- Lightweight construction and interiors: Forming frames for doors, partitions, and various interior applications.

Thanks to their lightweight nature, easy installation, and cost-effectiveness, purlins made by the CZ Combination Purlin Machine are becoming increasingly dominant in the construction industry.

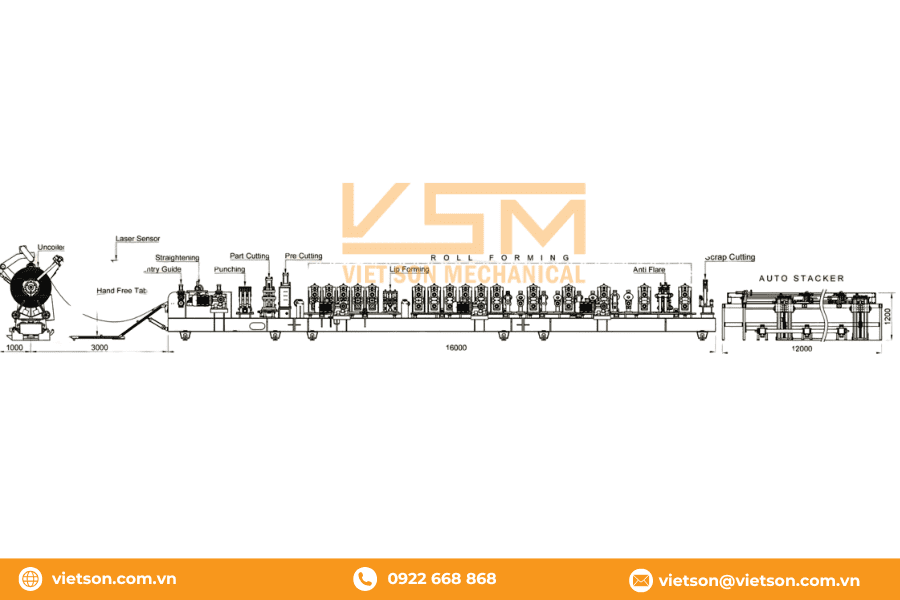

Key Components and Technical Specifications of the CZ Combination Purlin Machine

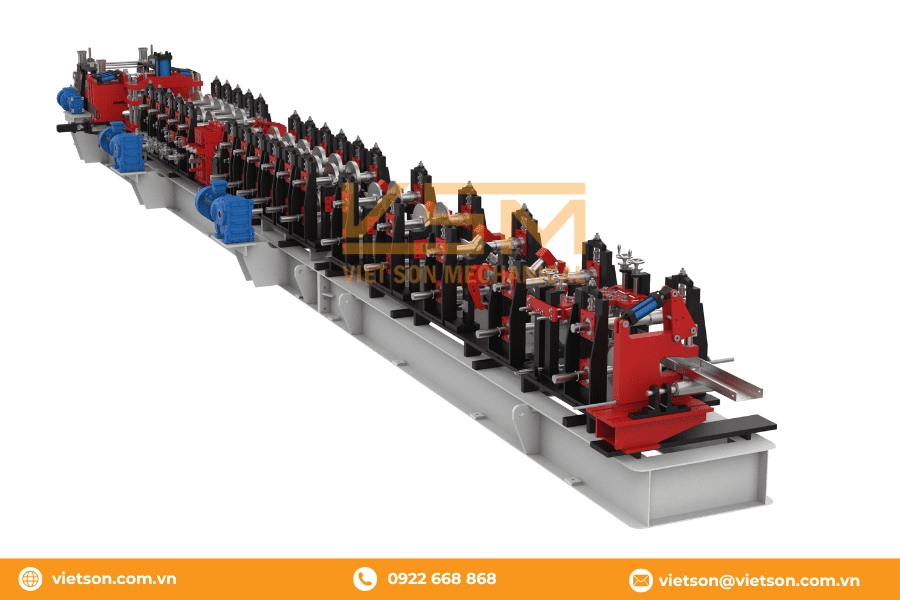

The main components of the CZ Combination Purlin Machine from Viet Son Mechanical include:

- Uncoiler

- Straightening

- Punching

- Part Cutting

- Lip Forming

- Roll Forming

- Anti Flare

- Scrap Cutting

| Model | CZ-EA Model |

| Power | Transmission: 2x15kw – 1/30

1×7.5kw – 1/30 Motor – pump: 11kw – 45cc Size changed: 3×1.5kw – 1/25 Punch table: 2×1.5kw |

| Weight of machine | 28 tons |

| Dimension | L=16m; W=2.5m, H=2.0m |

| Forming speed | 16 – 20 meters/minute

(w/o punching) Lower with punching |

| Roller stations | – Lip forming: 06

– Side forming: 11 – Pulling stations: 05 – Anti-flare adjustment: 01 |

| Transmission system | Electric motor and Gear box |

| Cutting system | Hydraulic cylinder |

| Cutting technology | Part-cutting and scrap cutting |

| Punching system | Hydraulic cylinder |

| Punching technology | 03 separate punching stations.

Position reached by servo |

| Control system | PLC, HMI automatic programmable |

| Size range | C100–C350 and Z100–Z350 |

| Size changed | Automatic by servo motor |

| Material thickness | 1.2 – 3.2 mm |

| Material width | For C: 200-563mm

For Z: 206-569m |

| Material Yield Strength | G300 – G550 Mpa |

How the CZ Combination Purlin Machine Benefits Light Gauge Steel Construction

Main and Secondary Beams for Roofs

C and Z purlins produced by the CZ Combination Purlin Machine serve as critical load-bearing elements for roofing systems, distributing loads to pillars and frames, ensuring stability against environmental factors.

Creating Structural Links

Purlins link major steel frame components, forming a unified, solid structure. Using standardized purlins from the CZ Combination Purlin Machine guarantees synchronized assembly and enhances the overall durability of the structure.

Reducing Overall Construction Weight

Light yet strong purlins reduce the overall structure’s weight, optimize foundation designs, save construction materials, and shorten construction time.

Increasing Design Flexibility

The ability to produce a wide variety of purlin sizes and types enables engineers to flexibly design light gauge steel, from simple to highly complex models.

Enhancing Aesthetics and Longevity

Purlins from the CZ Combination Purlin Machine feature smooth surfaces, precise dimensions, minimized warping, and improved corrosion resistance, ensuring high aesthetics and extended service life for the structures.

Viet Son Mechanical to Attend Sydney Build Expo 2025

To showcase the latest advancements in light gauge steel house solutions and machinery manufacturing technology, Viet Son Mechanical is proud to participate in the Sydney Build Expo 2025, taking place on May 7–8, 2025, at the International Convention Centre (ICC Sydney).

At this event, Viet Son Mechanical will present:

- Comprehensive, optimized light gauge steel construction solutions.

- Smart Frame technology – an automated, high-precision steel frame production system aligning with modern construction trends.

- Featured products: the CZ Combination Purlin Machine, with fast changeover capabilities and high automation, directly serving steel structure, warehouse, residential, and industrial projects.

This event offers Viet Son Mechanical the opportunity to introduce its advanced machine manufacturing capabilities internationally and seek potential partners and expand into global markets.

In today’s construction industry, which demands rapid progress, high quality, and cost optimization, investing in a CZ Combination Purlin Machine is a strategic choice for businesses looking to enhance production capacity, take control of material supplies, and achieve a competitive advantage.

With over 15 years of experience, proven production capabilities, strict quality control, and dedicated after-sales service, Viet Son Mechanical is proud to be a trusted partner, delivering durable, high-performance, and economically efficient CZ Combination Purlin Machines.

CONTACT VIET SON MECHANICAL FOR THE EARLIEST QUOTATION

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Cu Chi, HCMC, Vietnam

- Office: 253 Dien Bien Phu St., Vo Thi Sau Ward, District 3, HCMC, Vietnam

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- YouTube: youtube.com/cokhivietson