In the construction industry, choosing between a light gauge steel house and traditional reinforced concrete structures is a crucial decision that affects cost, construction time, and overall project efficiency. In this article, VIET SON MECHANICAL will help you clearly understand the differences between these two structural systems and why the light gauge steel house is becoming increasingly popular.

1. Definitions of Light Gauge Steel House and Traditional Reinforced Concrete

1.1. What is a Light Gauge Steel House?

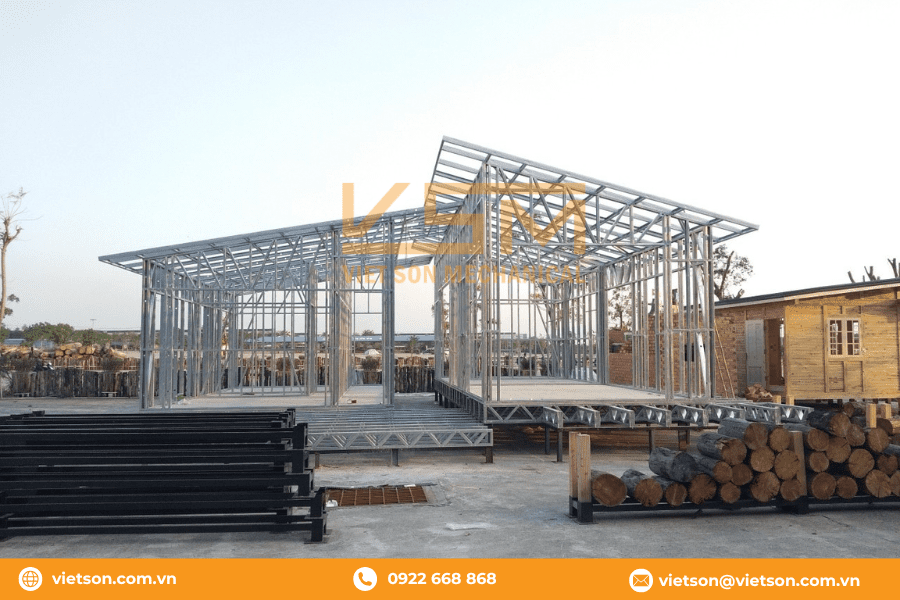

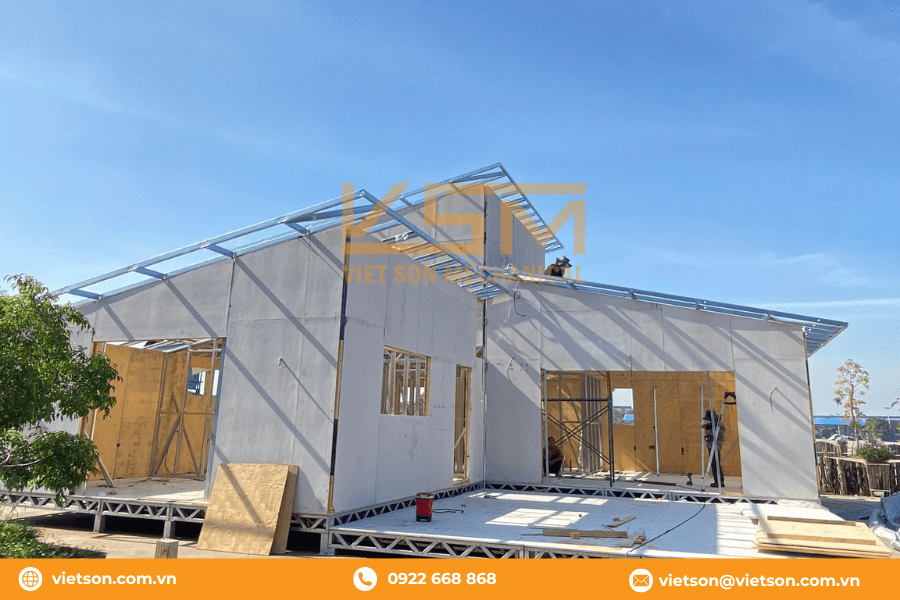

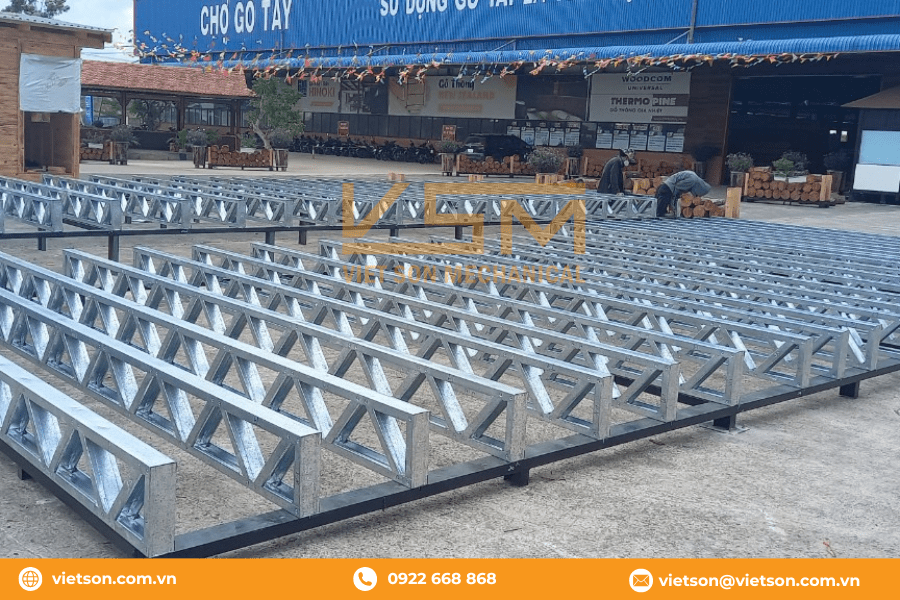

A light gauge steel house is a structural system made from lightweight galvanized steel with high strength, assembled in a modular format. This system often utilizes advanced technology such as CNC cutting and design software to ensure near-perfect accuracy.

1.2. What is Traditional Reinforced Concrete?

Traditional reinforced concrete structures are the most widely used in construction, consisting of concrete combined with steel reinforcement to enhance strength. These structures are durable but require long construction time, a large workforce, and are significantly affected by weather conditions.

2. Comparison Between Light Gauge Steel House and Reinforced Concrete

| Criteria | Light Gauge Steel House | Reinforced Concrete |

| Weight | 30–50% lighter | Heavy, affects foundation design |

| Construction Time | 50–70% faster | Long duration, many steps |

| Durability | Strong, good load-bearing, minimal shrinkage | Durable, but may crack or degrade over time |

| Expandability | Flexible, easy to upgrade or modify | Difficult to expand, may require demolition |

| Cost | Saves 10–30% compared to reinforced concrete | Higher due to material and labor costs |

| Aesthetics | Easy to shape, fits various styles | Limited flexibility in design |

| Recyclability | 90% of materials recyclable | Difficult to recycle, environmentally harmful |

3. Advantages of the Light Gauge Steel House

- Lightweight, rust-resistant, long-lasting material: High-strength AZ150 G550 aluminum-zinc coated steel provides excellent corrosion resistance. Lifespan of over 30 years with minimal deformation.

- High precision and reliability: All components are CNC-designed and produced in a closed system, ensuring exceptional accuracy and reliability.

- Aesthetic and safe: Assembled using hot-dip galvanized Wakai screws from Japan – no welding or painting, reducing fire risks.

- Fast installation: Saves 50% construction time compared to traditional houses thanks to lightweight frames and pre-coded components that are easy to transport and assemble.

- No additional costs: Designed with specialized software, materials are CNC-cut based on design data, minimizing waste.

4. Applications of the Light Gauge Steel House

- Fast construction, no curing time required like concrete.

- Cost-saving due to reduced material usage, labor, and time.

- Flexible design options for various types of structures.

- High durability and weather resistance.

- Environmentally friendly, minimal construction waste, recyclable materials.

5. Estimated Costs for a Light Gauge Steel House

| Structure | Price per m² | Weight per m² | Price per kg |

| Wall and roof frames | 1,500,000 VND/m² | ~30 kg | 50,000 VND/kg |

| Floor frame | 600,000 VND/m² | ~12 kg | 50,000 VND/kg |

6. Light Gauge Steel House Services by VIET SON MECHANICAL

VIET SON MECHANICAL offers full-package services for light gauge steel house projects, including consultation – design – production – installation – and warranty, ensuring optimal and long-lasting solutions for clients.

6.1. Consultation & Design

- Site survey: VIET SON MECHANICAL engineers conduct on-site evaluations to assess terrain, construction conditions, and client needs.

- Optimal design consultation: Offers suitable structural solutions to ensure aesthetics, load-bearing capability, and cost efficiency.

- Detailed blueprints: Uses modern 3D design software to simulate structures and provide a clear visual for clients.

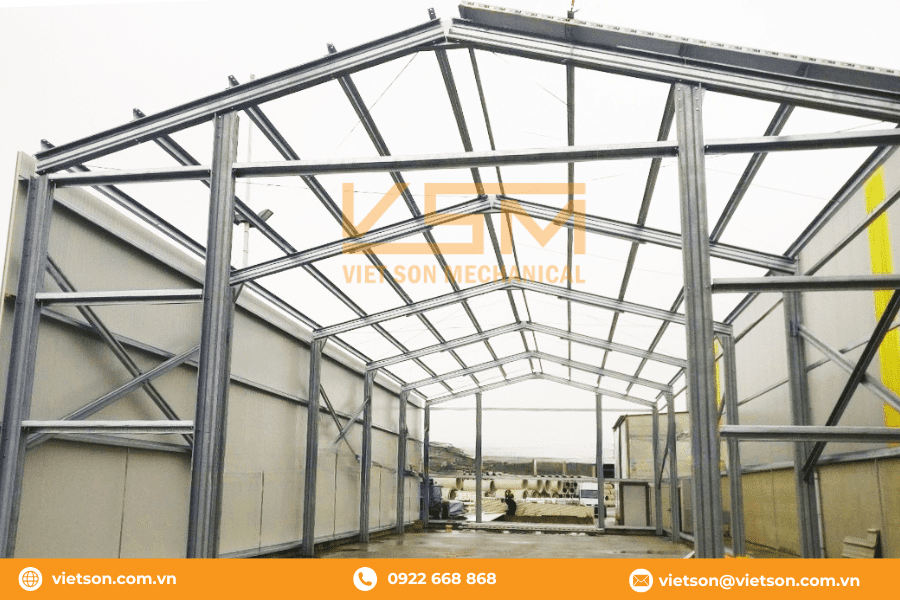

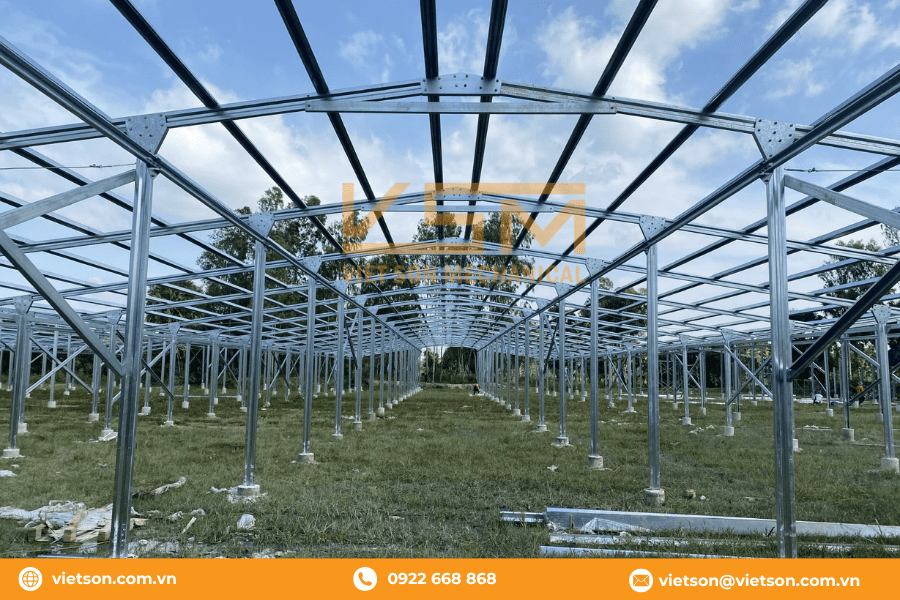

6.2. Manufacturing & Fabrication

VIET SON MECHANICAL owns a modern mechanical fabrication facility using CNC technology to produce high-precision steel components.

- Premium materials: Uses hot-dip galvanized steel to enhance corrosion resistance and increase structure longevity.

- CNC cutting technology: Ensures dimensional accuracy, speeding up on-site assembly.

- Strict quality control: Inspects each component before delivery to meet rigorous technical standards.

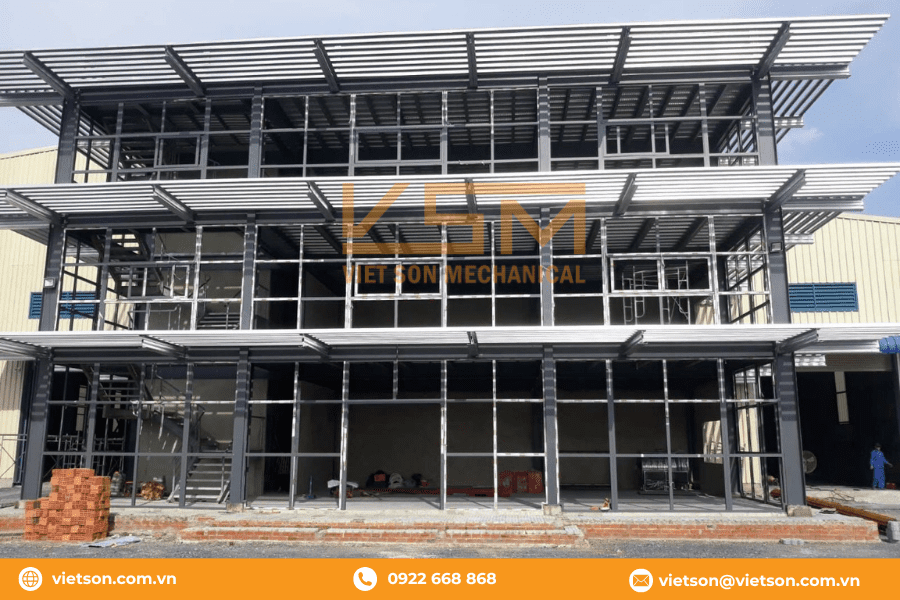

6.3. Construction & Installation

- Quick assembly: With prefabricated components, on-site construction takes only 2–6 weeks—50–70% faster than concrete.

- Strong structure: The steel frame is secured with high-strength bolts for stability and load-bearing capacity.

- Safety assurance: Workers are fully equipped and comply with safety regulations.

- Waterproof and insulated: Combined with heat- and sound-insulated roofing for optimal living and working conditions.

6.4. Warranty & Maintenance

- Regular maintenance: Inspects structural stability and material durability.

- Support for modifications and upgrades: VIET SON MECHANICAL assists with expanding or adjusting structures as needed.

- 24/7 customer support: Rapid technical response to any issues during use.

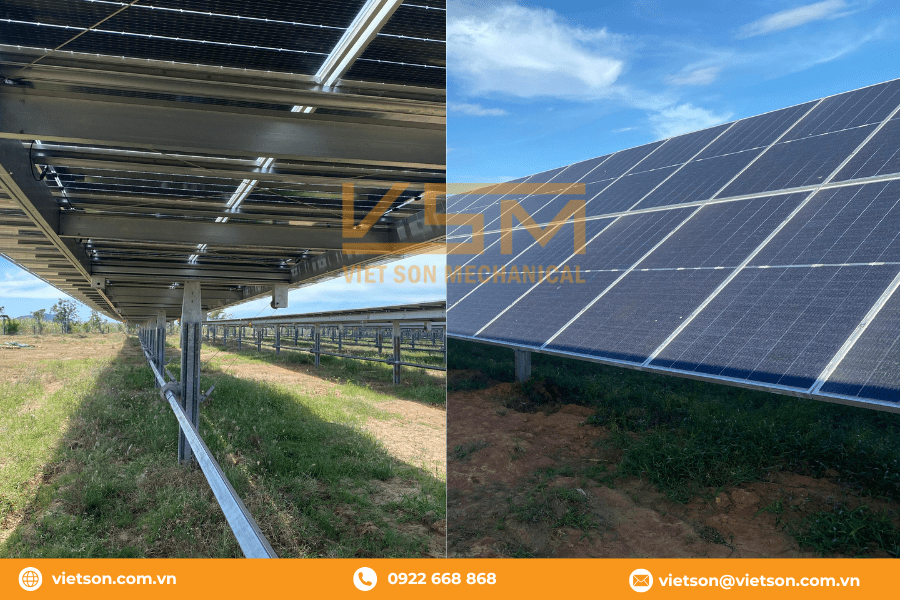

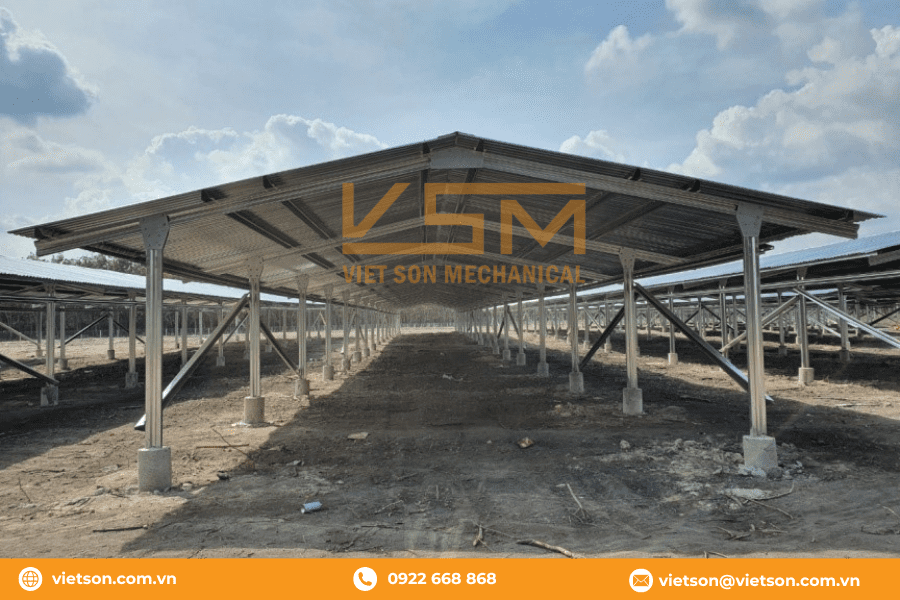

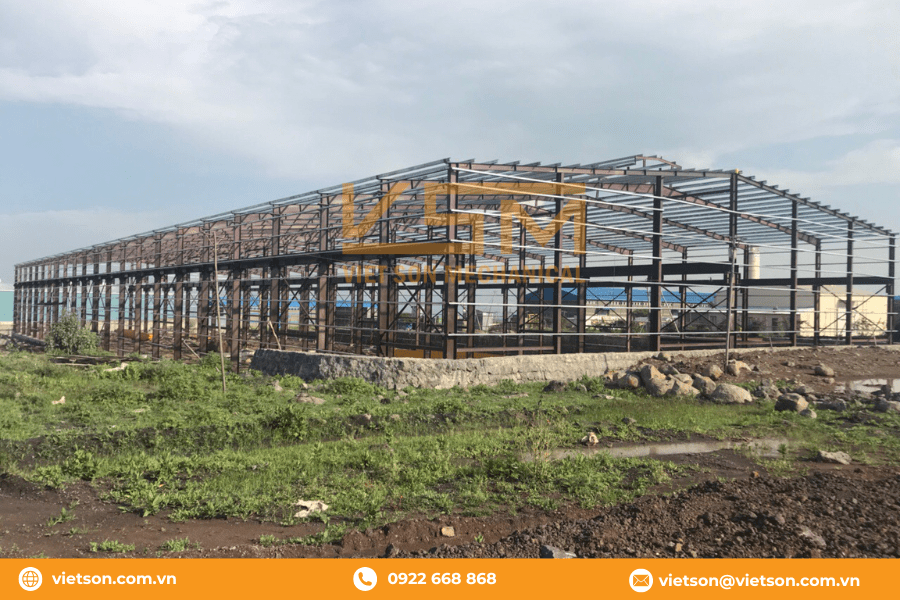

7. Projects by VIET SON MECHANICAL

With extensive experience and reputation, VIET SON MECHANICAL has successfully completed many high-quality projects both domestically and internationally. Notable examples include:

- Solar panel structure – Binh Thuan, Vietnam

- Coastal resort housing – Philippines

- Warehouse project – Belgium

- Agricultural farm – Tay Ninh, Vietnam

- Mushroom farming facility

- Factory project – Ethiopia

- Employee housing – Cambodia

- Office building – Tan Phu Trung Industrial Park

- VIA Coffee shop

- Tavico project

VIET SON MECHANICAL specializes in the design, manufacturing, and installation of steel structure houses. With many years of experience in the mechanical industry, we provide sustainable, high-quality, and cost-effective construction solutions tailored to our clients’ needs.

Contact us for more details:

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Zone, Cu Chi, Ho Chi Minh City, Vietnam

- Office: 253 Dien Bien Phu St., Vo Thi Sau Ward, District 3, Ho Chi Minh City, Vietnam

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- YouTube: youtube.com/cokhivietson