As the construction industry shifts rapidly toward efficiency, optimization, and sustainability, shaped steel has become increasingly important in modern structural systems. In addition to delivering technical efficiency, shaped steel contributes to shorter construction time and lower total project costs. As a leading manufacturer and supplier of shaped steel, Viet Son Mechanical proudly supports hundreds of projects across Vietnam, from industrial factories to residential buildings.

1. Modern Construction Trends and the Role of Shaped Steel

As building standards increasingly emphasize industrialization, fast construction, and cost-effectiveness, traditional materials like reinforced concrete are gradually being replaced by lightweight steel structures. Among them, shaped steel stands out as a superior solution due to its high load-bearing capacity, ease of installation, and adaptability to various project types.

Shaped steel is widely used in:

- Pre-engineered steel buildings

- Logistics centers

- Cold storage and industrial warehouses

- Modular residential buildings

- Showrooms, supermarkets, and steel-frame offices

- Power substations, solar panel structures, and technical stations

2. Types of Shaped Steel Provided by Viet Son Mechanical

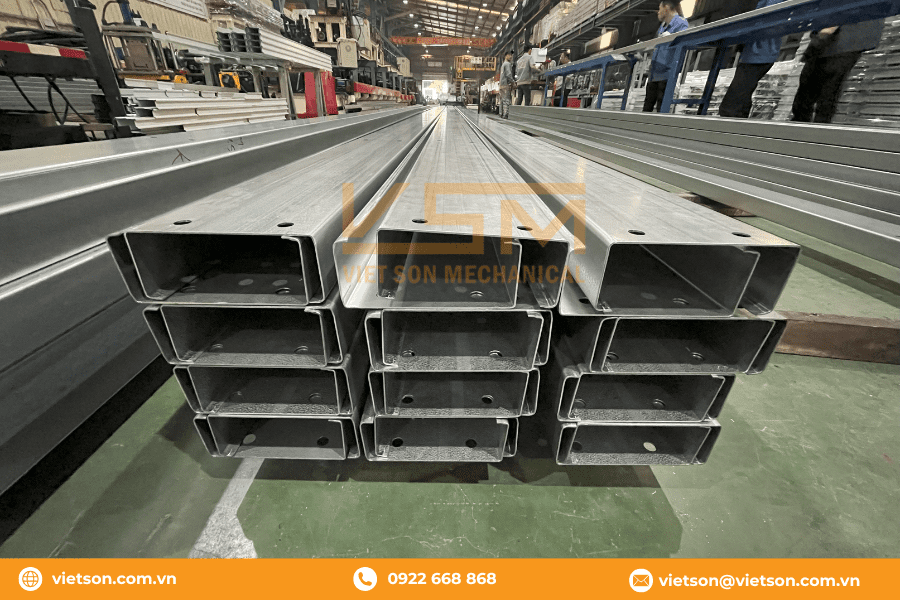

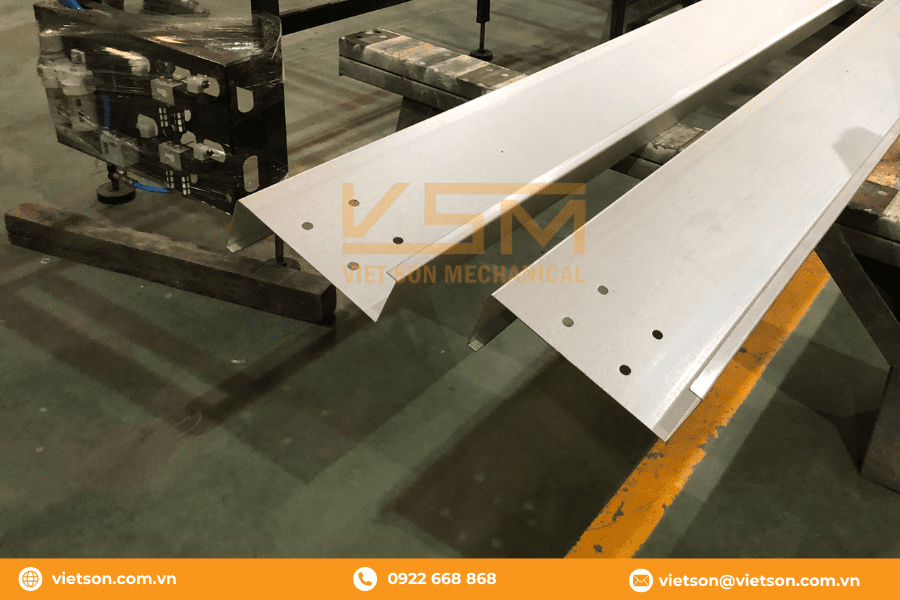

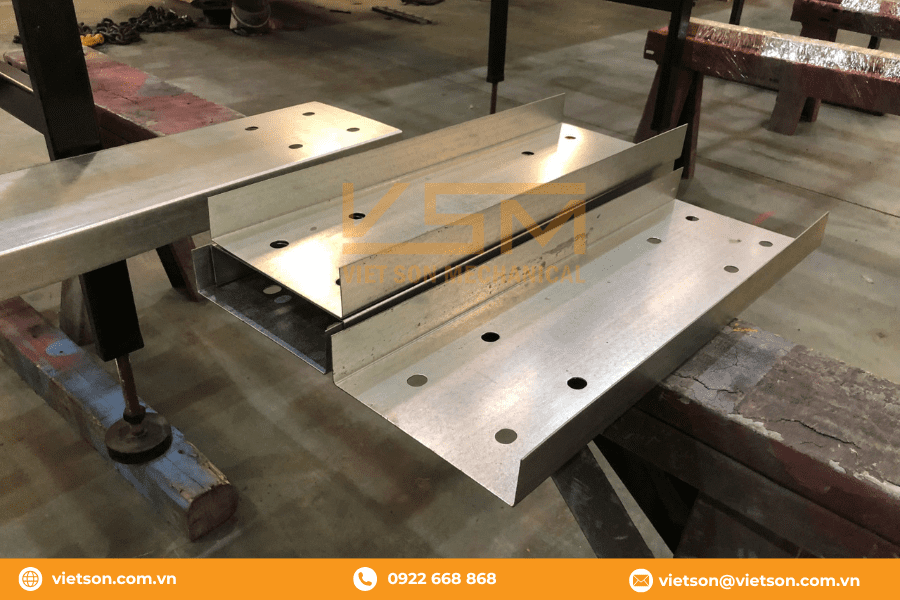

Viet Son Mechanical is one of the few enterprises in Vietnam that specializes in manufacturing and supplying high-quality cold-formed shaped steel products, including:

U, C, Z, G Steel – Purlin Solutions for Industrial Structures

- C Purlin: Commonly used in secondary frames, wall purlins, or medium-load structural elements.

- Z Purlin: Ideal for sloped roofs with interlocking features for quick and efficient assembly.

- U Purlin: A simple, durable section used for boundary frames, rafters, and secondary support.

- G Purlin: Often applied in bracing systems, lightweight trusses, or structural reinforcement components.

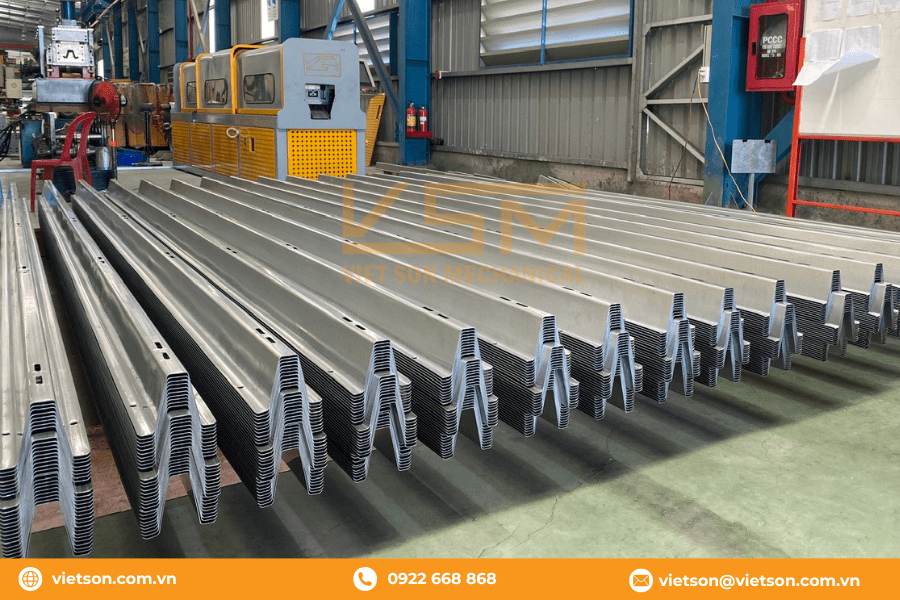

Omega and Sigma Steel – Core Profiles for Modular Buildings

- Omega Purlin: Omega-shaped cross-section designed to evenly distribute loads, used in partition walls, ceilings, or light wall structures.

- Sigma Purlin: Designed with longitudinal folds to increase vertical stiffness, ideal for multi-story modular buildings and lightweight residential structures.

Steel Floor Decking – Composite Concrete Floor System

- Corrugated profile with embossments for concrete bonding

- Widely used for mezzanine floors, multi-story factory flooring, and showroom decks

3. Key Advantages of Shaped Steel in Modern Construction

Optimized weight, increased efficiency

Compared to hollow or solid steel sections, shaped steel is up to 40% lighter, reducing foundation load and saving on substructure materials.

High load capacity and structural stability

Optimized cross-sectional designs (Z, Sigma, Omega, etc.) provide excellent performance in resisting deflection, torsion, and bending.

Quick assembly, faster project completion

Products can be pre-fabricated at the factory and bolted on-site without welding, reducing construction time by 30–50%.

Cost-effective and easy to maintain

More affordable than hot-rolled sections or traditional materials. Galvanized surfaces offer long-term rust protection of up to 20–30 years.

4. Real-World Applications in Modern Construction

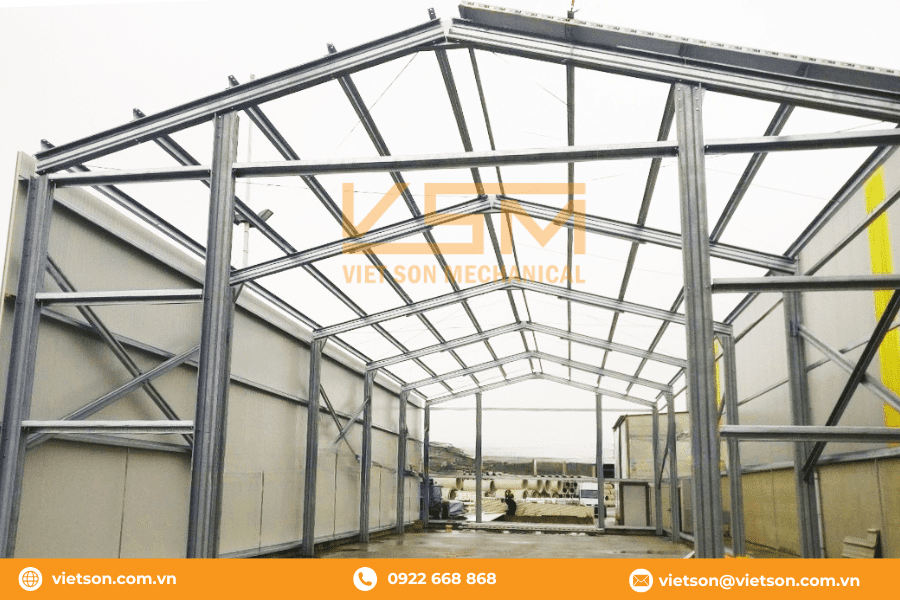

Industrial factories and warehouses

- Main frame: hollow steel

- Secondary frame: C/Z shaped steel, G-type bracing

- Floor decking: used for mezzanine levels and service platforms

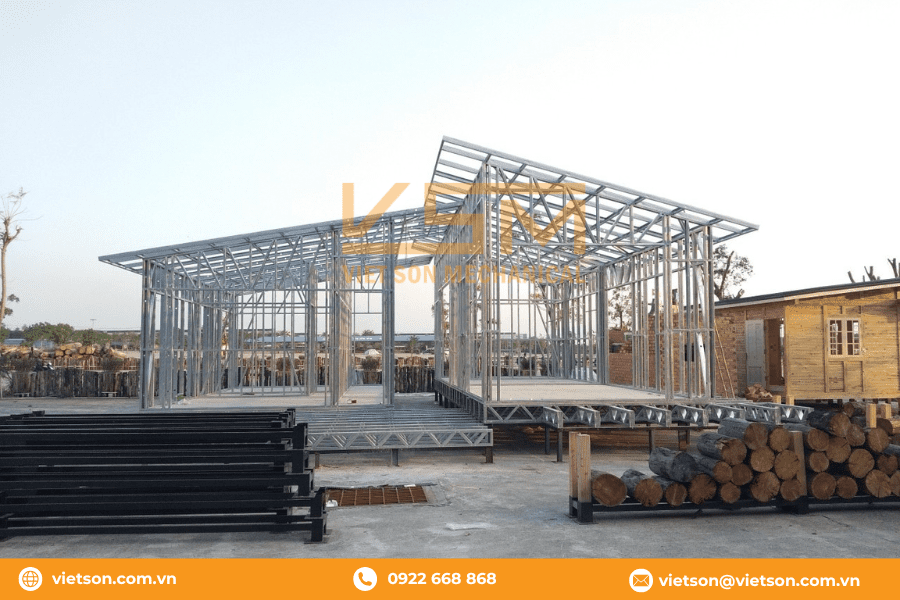

Modular residential buildings and urban lightweight homes

- Wall system: Omega steel

- Roofing: C steel with Z purlins

- Ceiling: Sigma steel combined with insulated panels

Showrooms and commercial centers

- Lightweight frame systems that maximize open spaces without columns

- Floor decking that reduces story height and enhances design flexibility

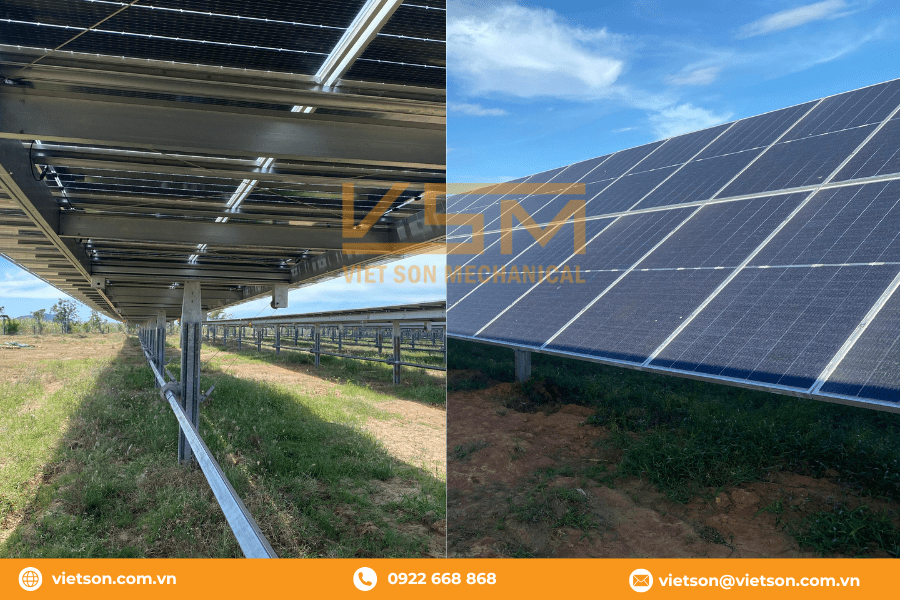

Solar farms and technical facilities

- Solar mounting systems using C/U/G shaped steel, optimized for outdoor durability and reduced structural load

5. Production Capabilities and Services at Viet Son Mechanical

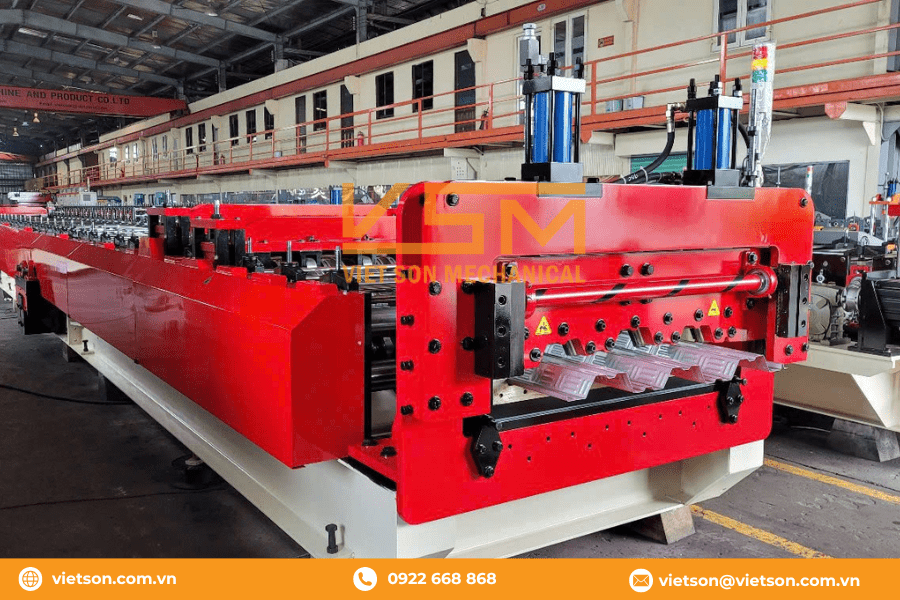

Automated Roll-Forming Technology

- Continuous production lines with high efficiency

- Custom fabrication of U, C, Z, G, Sigma, Omega profiles and steel floor decking

Engineering Consultation and Structural Design Support

- A team of mechanical and civil engineers to assist with drawing reviews

- Load analysis and optimized profile recommendations

Nationwide Logistics Network

- On-time delivery

- Secure packaging to ensure product integrity at the job site

Quality Commitment and After-Sales Policy

- Galvanized products meet JIS and ISO standards

- Warranty and long-term technical support throughout the project lifecycle

6. Why Choose Viet Son Mechanical as Your Shaped Steel Partner?

In today’s demanding construction environment, where quality and timelines are critical, Viet Son Mechanical is a reliable partner thanks to its strong production capacity, field-proven experience, and technical service excellence.

Extensive experience

Over 15 years supporting industrial, residential, and energy projects — from consulting and fabrication to accurate, on-time delivery.

In-house production – no intermediaries

Manufacturing done entirely in-house enables us to control timelines, ensure quality, and offer competitive pricing across our full range of shaped steel products.

Comprehensive solutions and on-site support

We offer support throughout the entire process — structural design consultation, custom fabrication, timely delivery, and ongoing technical assistance.

Proven credibility

Viet Son Mechanical has delivered numerous projects nationwide and is trusted by major contractors and investors who prioritize efficiency, durability, and cost optimization.

CONTACT US:

- Factory: Lot C2-7, Street N7, Tan Phu Trung Industrial Park, Cu Chi, Ho Chi Minh City, Vietnam

- Office: 253 Dien Bien Phu Street, Vo Thi Sau Ward, District 3, Ho Chi Minh City

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: Cơ khí Việt Sơn

- YouTube: youtube.com/cokhivietson