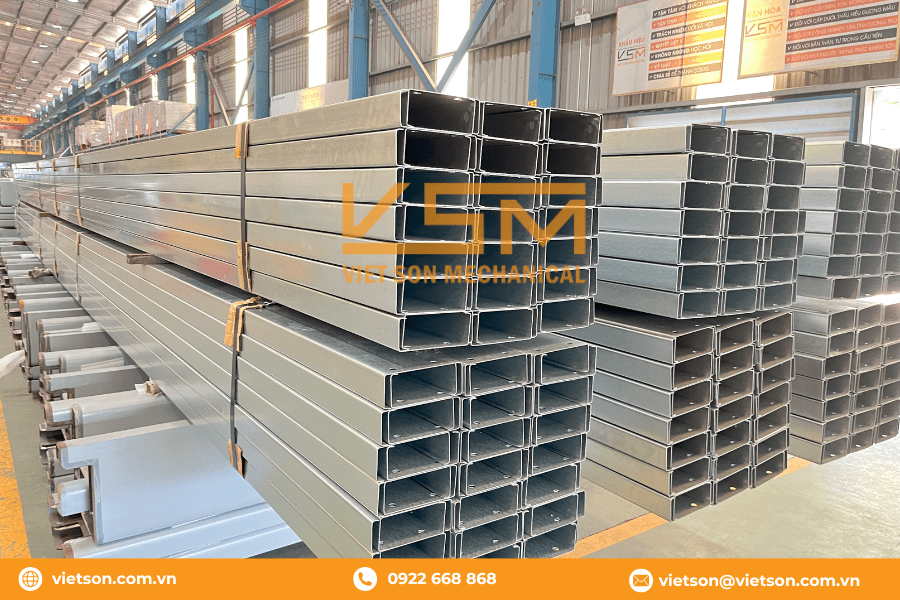

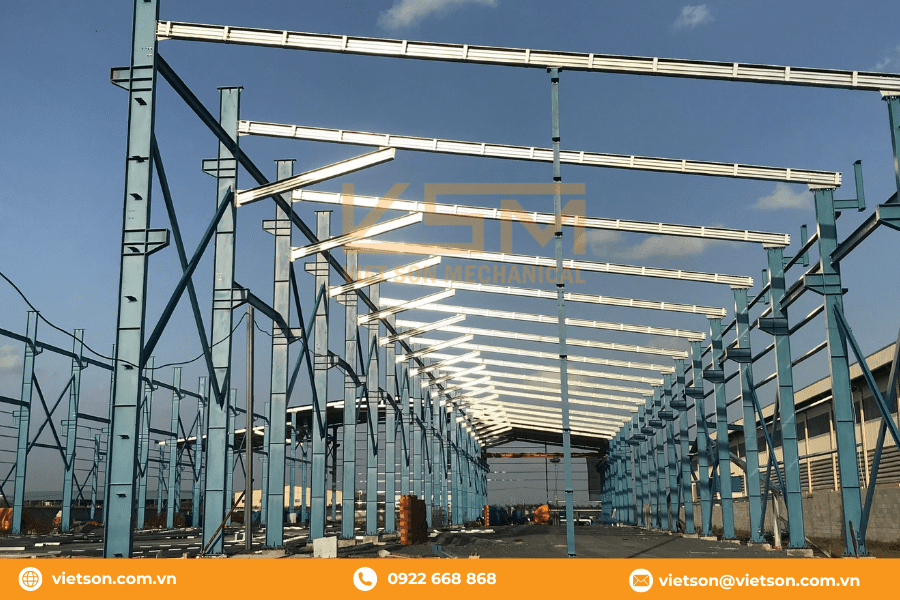

Galvanized purlin is one of the essential structural materials in modern construction. Thanks to its excellent load-bearing capacity, high corrosion resistance, and long lifespan, galvanized purlin is widely used in residential buildings, factories, pre-engineered steel structures, solar power systems, roofing frameworks, and industrial warehouses.

At Viet Son Mechanical Co., Ltd., we specialize in manufacturing and supplying high-quality galvanized purlins in various sizes and specifications to meet the diverse needs of different construction sectors.

What is Galvanized Purlin?

Galvanized purlin is a cold-formed steel profile coated with a layer of zinc through electro-galvanizing or using galvanized steel coils (GI – Galvanized Iron). This zinc layer helps protect the steel from rust, enhances durability, and extends the product’s lifespan, especially when used in harsh outdoor environments.

Key Advantages of Galvanized Purlin by Viet Son Mechanical

Standard-grade steel materials

Viet Son Mechanical produces Galvanized Purlin from premium cold-rolled steel, coated with electro-galvanized or GI (Galvanized Iron) coils. All materials comply with technical standards for enhanced corrosion resistance and durability.

Stable durability – corrosion resistance

The zinc layer is uniformly coated on the steel surface, protecting it from oxidation. It is ideal for tropical climates like Vietnam. Cold-formed Galvanized Purlin can last from 20 to 30 years without requiring repainting like black steel purlins.

Flexible customization on demand

Viet Son Mechanical manufactures Galvanized Purlin based on customer drawings and specifications, supporting thicknesses from 1.2mm to 3.0mm and variable lengths suitable for different construction needs.

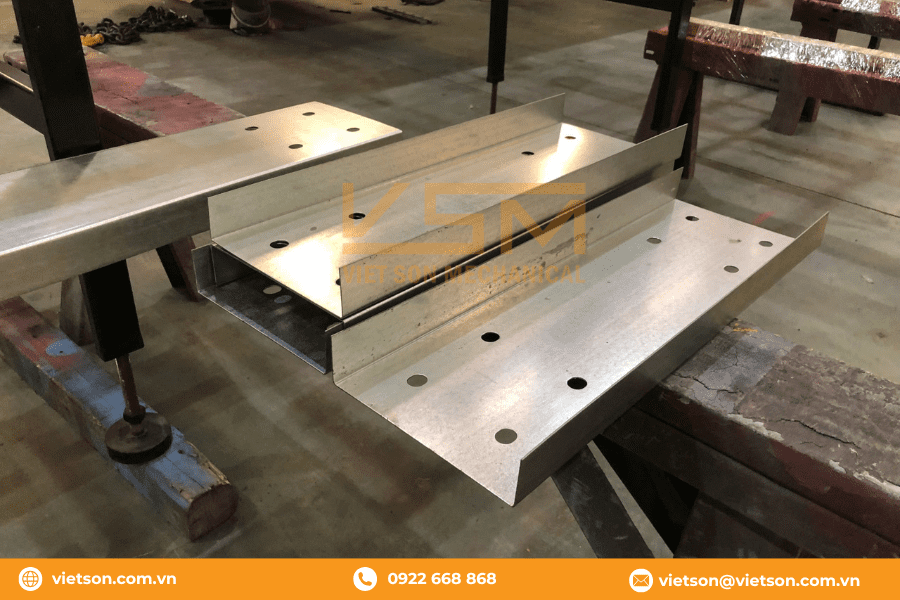

High-precision and aesthetic finish

Manufactured using automated forming lines, each Galvanized Purlin has accurate dimensions, smooth surfaces, and clean cuts, making installation quick and labor-saving.

High strength-to-weight ratio

Compared to black steel, Galvanized Purlin offers greater strength at a lighter weight, reducing the total load on the roof structure—especially effective for large-span or lightweight framing projects.

Popular Types of Galvanized Purlin at Viet Son Mechanical

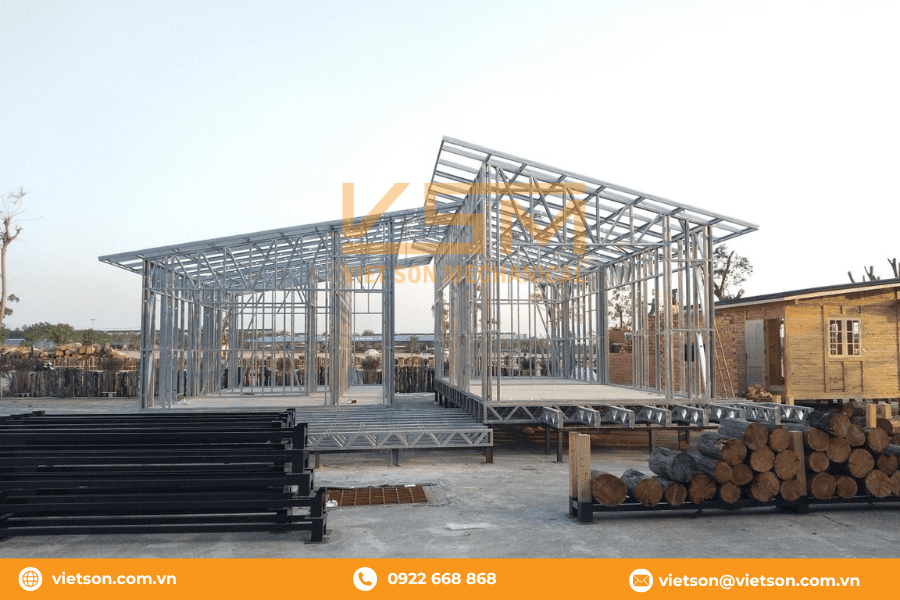

1. C Purlin

- Shape: C-shaped profile

- Common sizes: C100, C150, C200, C250, C300, C350

- Applications: Roof trusses, horizontal purlins for factories, pre-engineered buildings, panel supports, and wind walls.

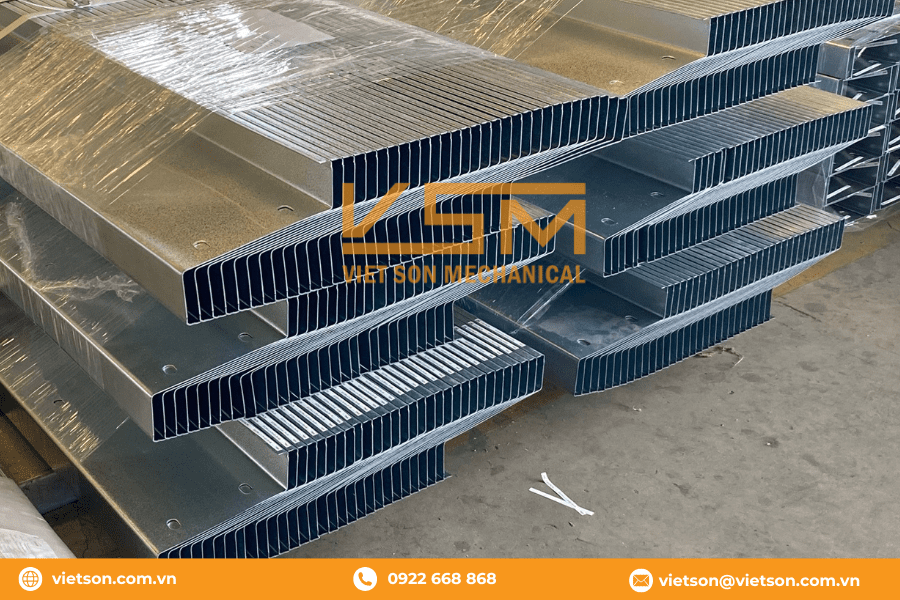

2. Z Purlin

- Shape: Z-shaped profile, ideal for overlapping joints

- Common sizes: Z100, Z150, Z200, Z250, Z300, Z350

- Advantages: Easy to install with overlapping joints, suitable for steep roofing structures

- Applications: Pre-engineered steel buildings, industrial construction, and warehouses.

3. U Purlin

- Shape: U-channel, used for main or secondary lightweight steel framing

- Common sizes: U75, U89

- Applications: Lightweight framing, false ceilings, and solar panel structures.

4. Omega Profile

- Shape: Ω-shaped profile, mainly used for ceiling frames and panel sub-frames

- Common sizes: A30, A62, A96

- Applications: Temporary housing, residential projects, factory ceilings.

5. Sigma Profile

- Advantages: Optimized for structural strength with a unique cross-sectional design

- Common sizes: S120, S150, S200, S250, S300, S350

- Applications: Roof trusses, lightweight floors, and heavy-load structures.

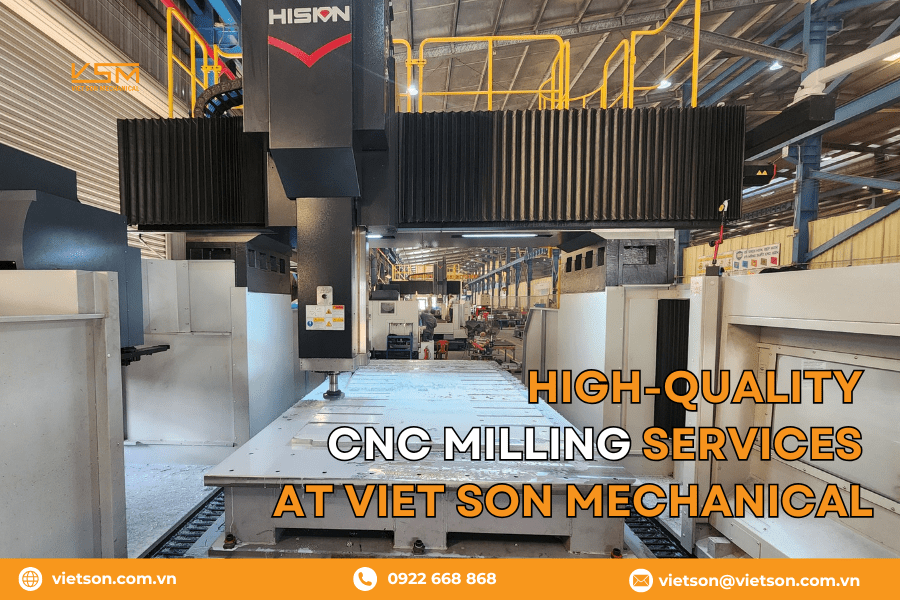

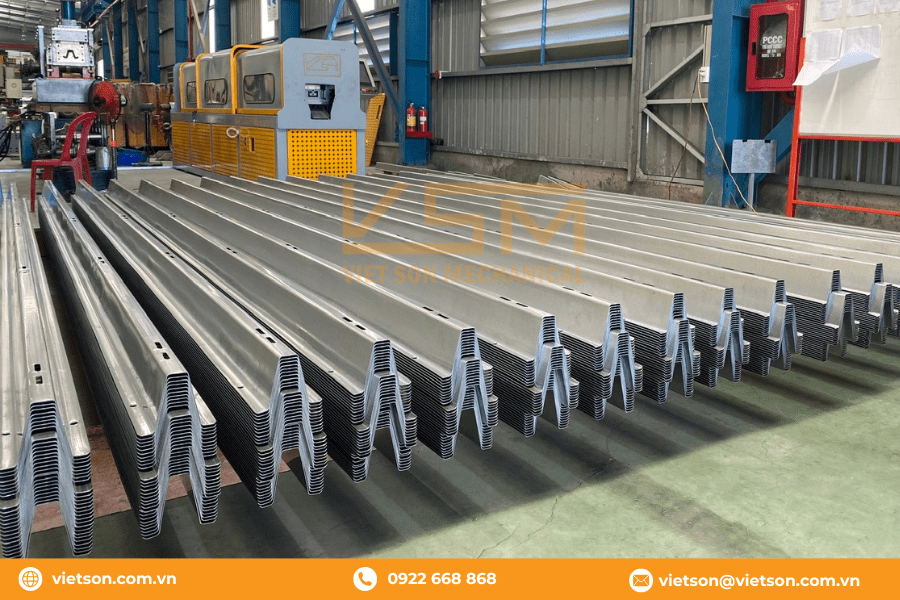

Advanced Manufacturing Technology – Quality Guaranteed

At Viet Son Mechanical, all Galvanized Purlin products are manufactured using a synchronized, high-precision production system that ensures consistency, accuracy, and aesthetics.

- C/Z/U Purlin Roll Forming Machines: Designed to shape common profiles like C100, Z150, and U120, with automatic punching and cutting based on drawings—ideal for pre-engineered, residential, and industrial projects.

- Sigma Beam Roll Forming Machine: Produces high-strength Sigma profiles for trusses, lightweight floors, and heavy-load structures.

- Omega Roll Forming Machine: Manufactures Omega profiles for ceiling grids, wall partitions, and insulation panels.

- SmartFrame System: An advanced automated system for light steel framing that controls cutting, punching, and profiling with high accuracy.

Every stage is strictly quality-controlled, from material input to finished products, ensuring each Galvanized Purlin delivered meets technical and mechanical standards.

Applications of Galvanized Purlin in Real-World Projects

Why Choose Galvanized Purlin from Viet Son Mechanical?

- Over 20 years of experience in mechanical fabrication

- Highly skilled engineering team with expert consultation

- Certified, high-quality products trusted by top clients

- Fast and timely delivery nationwide

- Competitive pricing with technical installation support

Contact Us for Galvanized Purlin Orders

Looking for a trusted Galvanized Purlin supplier? Contact Viet Son Mechanical today for expert consultation and competitive quotes.

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Cu Chi, Ho Chi Minh City, Vietnam

- Office: 253 Dien Bien Phu Street, Vo Thi Sau Ward, District 3, Ho Chi Minh City

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson?locale=vi_VN

- YouTube: youtube.com/cokhivietson