1. Vietnam – A New Destination for CNC Precision Machining

As production costs in Germany and across Europe continue to rise, German industrial companies are expanding their supply chains to Asia. Vietnam is emerging as a new hub for CNC Precision Machining, thanks to three key factors: quality, competitive cost, and flexibility.

German customers, well-known for their strict requirements on tolerance, precision, and certifications, will only partner with suppliers that can prove:

- Advanced CNC technology that meets European standards.

- Transparent ISO-certified quality management systems.

- On-time delivery capabilities and long-term cooperation commitment.

2. Vietnam’s Capabilities in CNC Precision Machining

- Skilled workforce: Vietnamese engineers and technicians are well-trained, with extensive experience working with partners from Japan, Korea, and the EU.

- Competitive production cost: 20–30% lower than Eastern Europe and nearly 40% lower than Germany, while still meeting ±0.01 mm tolerances.

- Developed industrial infrastructure: Concentrated industrial zones and clusters, with strong logistics connectivity.

3. Competitive Advantages of Viet Son Mechanical in CNC Precision Machining

As a representative of Vietnam’s mechanical industry, Viet Son Mechanical stands out with unique strengths:

- Modern equipment: Investment in 3–5 axis CNC machines, large-scale CNC milling machines, and high-power laser cutting systems, ensuring precision up to ±0.005mm.

- International standard processes: Implementation of ISO 9001:2015, strict quality control from design to production.

- Experienced engineering team: Over 15 years in the industry, with proven collaboration with FDI partners.

- Flexible production capacity: Capable of handling both small-batch and mass production orders, shortening lead time while maintaining top quality.

- Comprehensive OEM & ODM solutions: Beyond machining, the company also provides design consulting and product optimization tailored for German customers.

4. German Customer Insights and How Viet Son Mechanical Responds

German customers focus on 5 key factors when selecting a partner:

- Absolute precision → Viet Son Mechanical ensures tight tolerances and 100% CMM inspection.

- Transparency & quality control → Clear QC reports, online audits, and factory tours.

Sustainability → Lean Manufacturing approach, optimized material usage, and waste reduction. - On-time delivery → ERP-based production management, committed to deadlines aligned with German standards.

- Cost-effectiveness & clarity → Transparent pricing structure, 20–30% more competitive than the EU market.

5. Why Choose Viet Son Mechanical as a Long-Term CNC Precision Machining Partner?

- Already exporting mechanical products to America, Australia, and Asia.

- Open to long-term cooperation models such as 3–5 year Frame Contracts with German enterprises.

- Sales and engineering teams fluent in English, ensuring smooth technical and business communication.

- Strong commitment to long-term cooperation, becoming a sustainable part of German customers’ supply chains.

6. CNC Machining Capabilities and Modern Machinery at Viet Son Mechanical

6.1. CNC Machining Capabilities of Viet Son Mechanical

Viet Son Mechanical stands out with a wide range of precision CNC machining services:

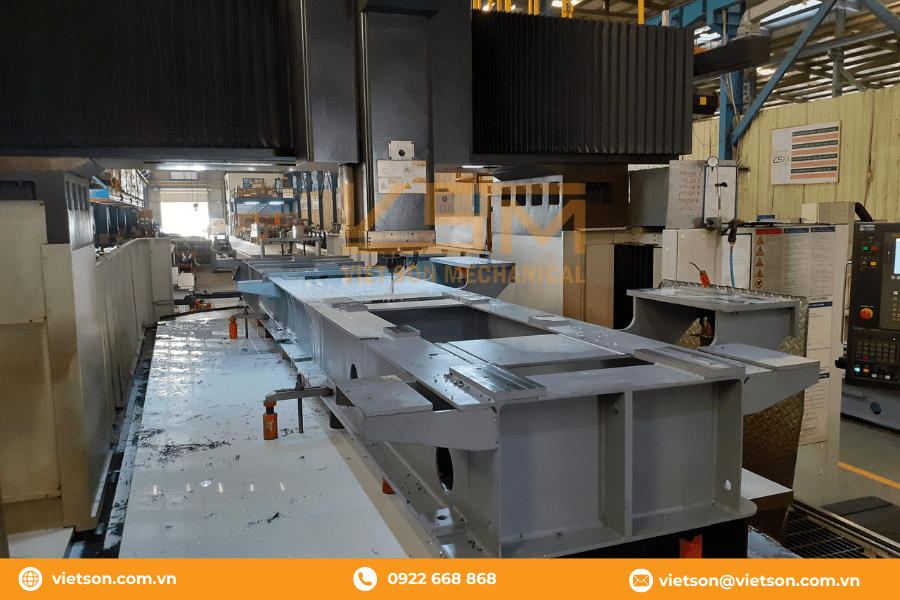

- CNC Milling: Ensures tight tolerances, capable of handling components from small to oversized parts.

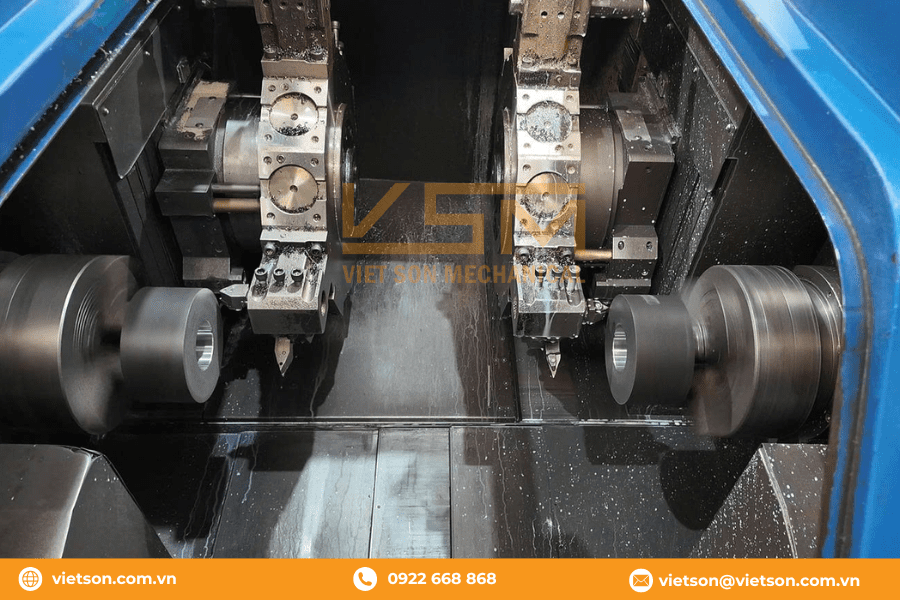

- CNC Turning: Ideal for shafts, gears, and round components requiring high precision.

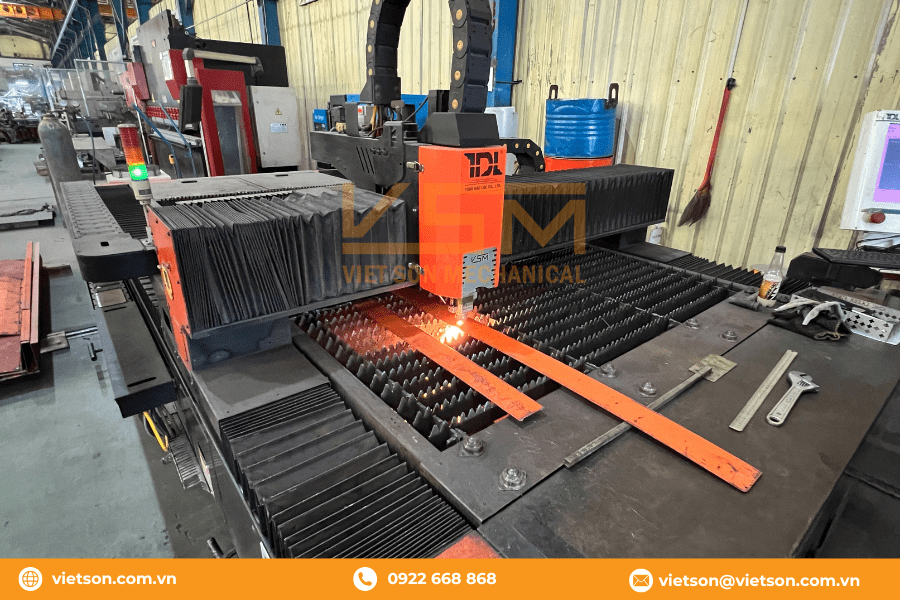

- CNC Laser Cutting: Efficiently cuts steel, stainless steel, and aluminum with smooth surfaces, meeting complex design requirements.

6.2. Modern Machinery System of Viet Son Mechanical

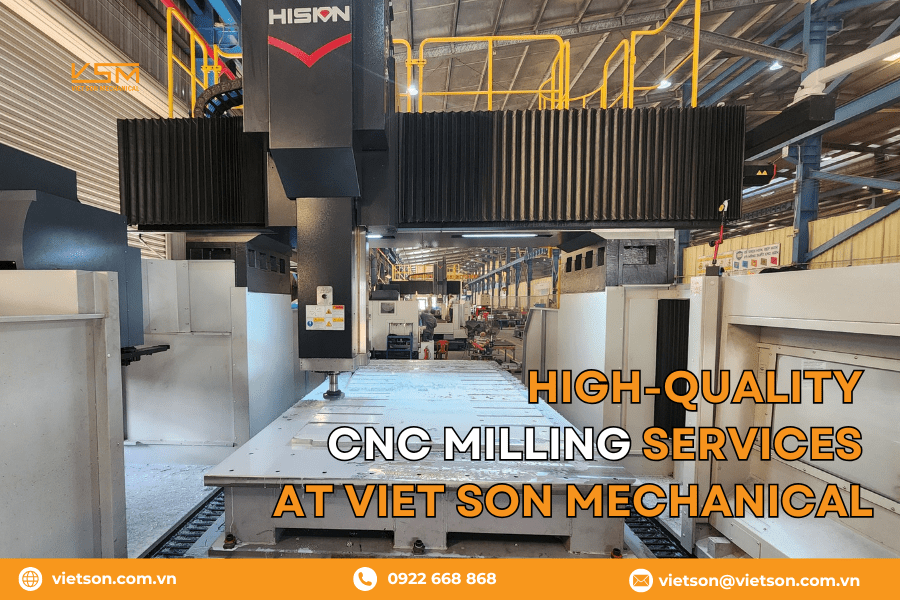

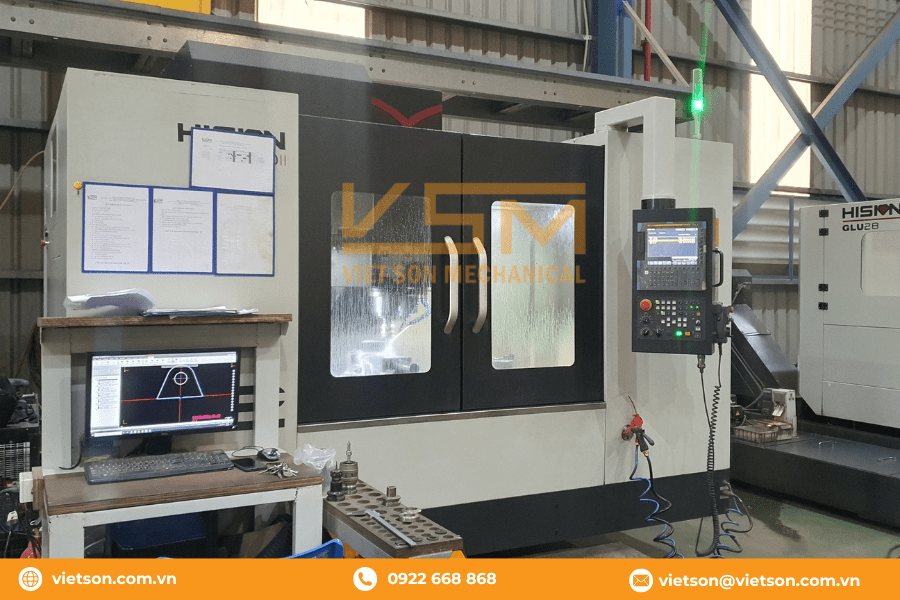

1.2m CNC Milling Machine – dedicated to machining small to medium-sized components.

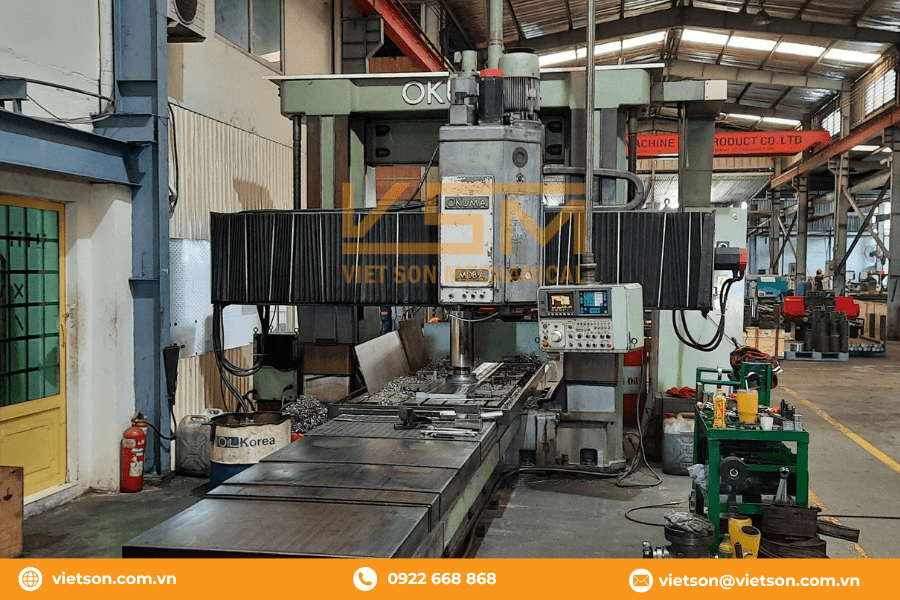

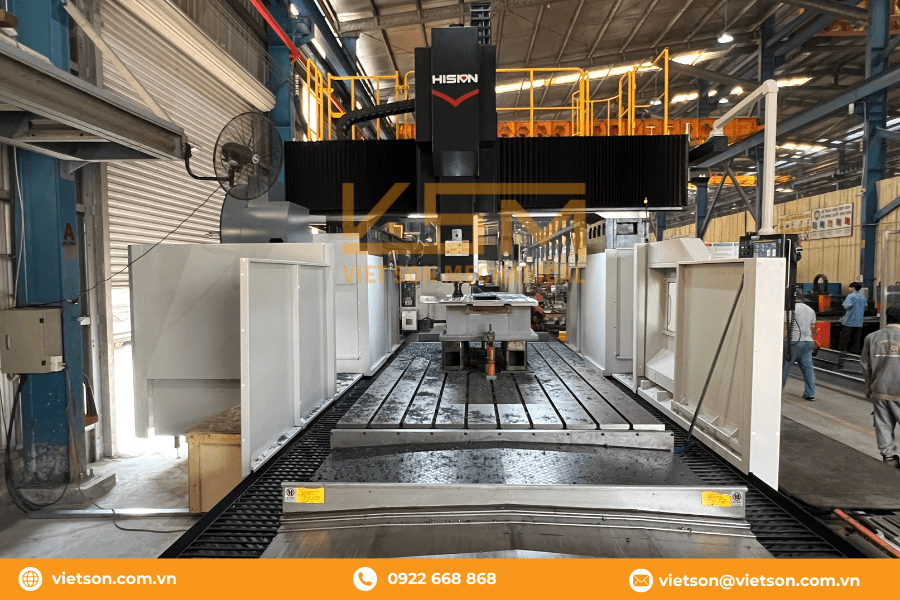

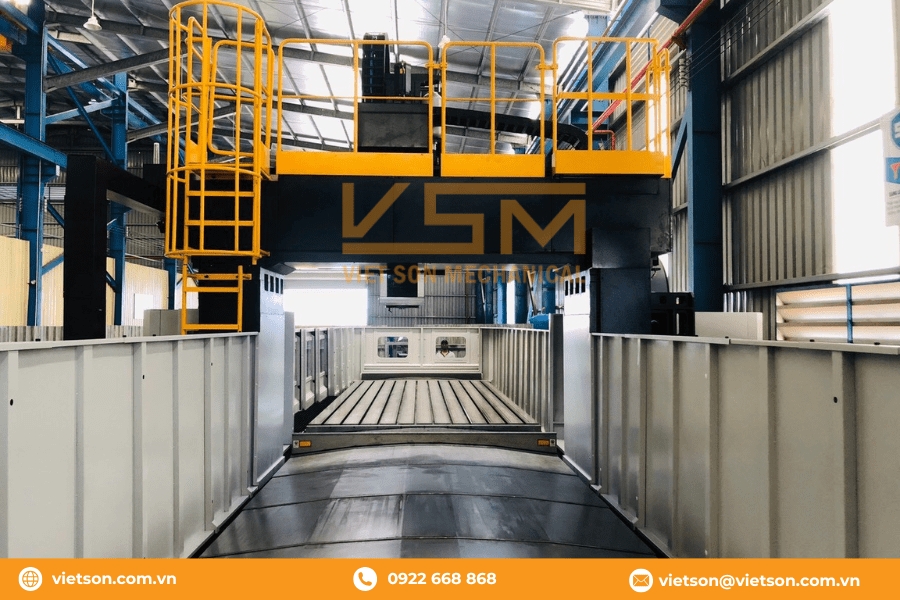

CNC Gantry Milling Machines (3m, 4m, 6.5m) – specialized in oversized and heavy-duty parts with ±0.005mm accuracy.

- 3m CNC Milling Machine

- 4m CNC Milling Machine

- 6.5m CNC Milling Machine

3m Lathe Machine – suitable for machining long shafts and large-diameter components.

2-axis CNC Lathe – optimized for mass production with stable accuracy.

High-power CNC Laser Cutting Machine – capable of cutting steel, stainless steel, and aluminum with smooth edges and high precision, suitable for complex components.

And many other modern machines that support the field of CNC machining.

7. Meet Viet Son Mechanical at EMO Hannover 2025

Don’t miss the opportunity to directly experience the CNC Precision Machining capabilities of Viet Son Mechanical at the world’s leading mechanical engineering exhibition – EMO Hannover 2025.

- Venue: Hannover Fairground, Hannover, Germany

- Date & Time: 9:00 – 18:00 | September 22 – 26, 2025

- Booth: J46 – Hall 6

At the exhibition, we will showcase:

- Oversize CNC Machining

- Customized Roll Forming Products

- OEM Machining Components

- Customized Automation Systems

Contact Us for More Information:

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Cu Chi, Ho Chi Minh City, Vietnam

- Office: 253 Dien Bien Phu Street, Xuan Hoa Ward, Ho Chi Minh City, Vietnam

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/

- Email: [email protected]

- Facebook: Viet Son Mechanical

- YouTube: youtube.com/cokhivietson