CNC milling machining is a modern solution in mechanical production, allowing for the creation of complex parts with high precision, meeting diverse needs in industries such as automotive, aerospace, and medical. This article will introduce CNC milling machining, popular types of milling machines, the implementation process, along with the outstanding advantages and applications of this technology.

I. Introduction to CNC Milling Machining

What is CNC Milling Machining?

CNC milling machining is a mechanical processing method that uses computer-controlled milling machines to cut and shape products from materials such as metals, plastics, wood, or other alloys. CNC stands for “Computer Numerical Control,” which refers to the automatic control of machinery based on pre-programmed instructions.

At Viet Son Mechanical, we take pride in being one of the leading units in the field of CNC milling machining in Vietnam. With many years of experience and investment in modern technology, we specialize in providing high-quality CNC milling machining services for customers both domestically and internationally. Our experienced technicians, along with advanced machinery systems, ensure that each product meets technical standards and the strict requirements of our clients.

Viet Son Mechanical is committed to providing optimal processing solutions, from design to production, helping customers save time and costs while ensuring product quality. With the motto “Quality is paramount,” Viet Son Mechanical continuously strives to affirm its position in the supporting industry and mechanical processing sector.

Contact for CNC Milling Machining Services:

Phone: 0922 668 868

Website: https://vietson.com.vn/

Email: [email protected]

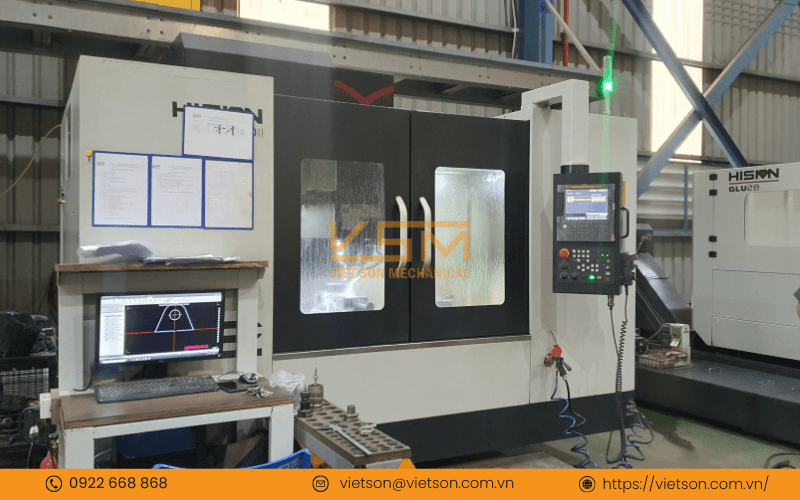

II. Types of CNC Milling Machines at Viet Son Mechanical

At Viet Son Mechanical, two common types of CNC milling machines used are the 3-axis CNC milling machine and the bed mill:

1. 3-Axis CNC Milling Machine:

This type of milling machine features three moving axes: X, Y, and Z. These axes allow for machining on flat surfaces, cavities, and grooves.

The 3-axis milling machine is suitable for machining simple to medium complexity parts, often found in products that require precision but are not overly complex.

Advantages: Easy to operate, high precision, time and cost-efficient.

Applications: Machining flat parts, cavities, and grooves in the fields of mechanical engineering, healthcare, electronics, and automotive.

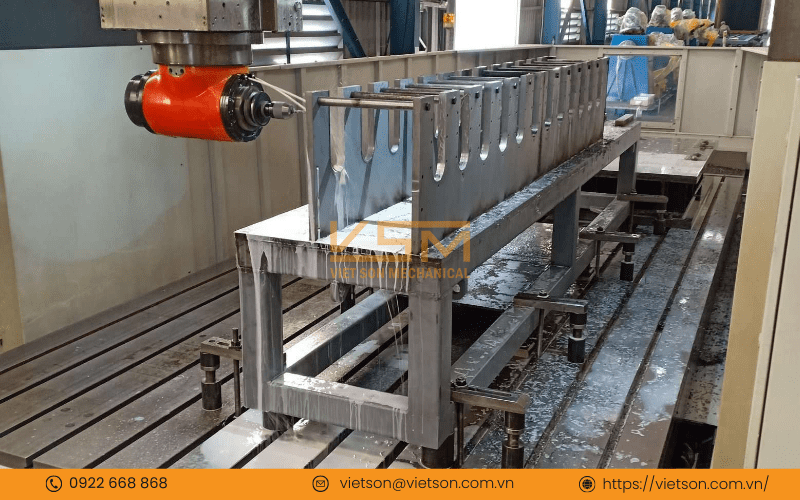

2. Bed Mill Machine:

This is a large milling machine with high load capacity and power. The table is fixed, with only the spindle moving, which helps reduce vibration and increase stability.

The bed mill is ideal for large, heavy, and complex parts that require high precision, commonly used in mold making and machining large components.

Advantages: High load capacity, stable, durable, suitable for machining large parts.

Applications: Machining large, heavy components such as frames and molds in the automotive, aerospace, and shipbuilding industries.

Both types of milling machines help Viet Son optimize efficiency and quality in machining projects, meeting the diverse requirements of customers.

III. CNC Milling Machining Process

The CNC milling machining process is an automated production method controlled by a computer, designed to create precise mechanical components from various materials such as metals, plastics, or alloys.

- Designing Technical Drawings (CAD – Computer-Aided Design):

- The first step in the process is to design detailed drawings of the component to be machined using CAD software (such as AutoCAD, SolidWorks).

- Characteristics: Drawings are typically in 2D or 3D format, containing complete technical specifications regarding dimensions, shapes, and technical requirements of the part.

- Machining Programming (CAM – Computer-Aided Manufacturing):

- After obtaining the CAD drawing, the CNC technician uses CAM software to convert the design into control codes for the CNC machine, usually G-code and M-code.

- G-code: Used to control the position and speed of the cutting tool.

- M-code: Used to control machine functions such as turning on/off, tool changes, and coolant pump operation.

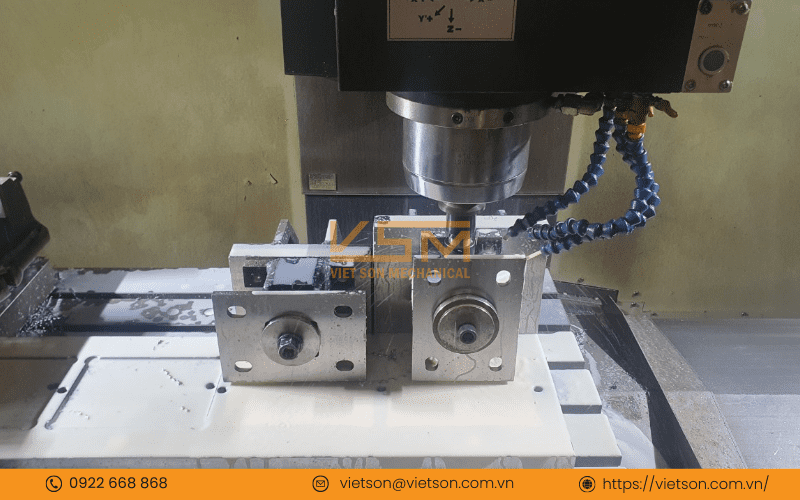

- Preparing Material and Setting Up the CNC Machine:

- Prepare raw material (metal, plastic, alloy) and securely fix it on the CNC machine table using vices or clamps.

- Install the appropriate milling cutter and calibrate the origin coordinates on the material for the machine to identify the cutting start point.

- Check machining parameters (spindle speed, feed rate, cutting depth) in the control software to ensure precise cutting.

- CNC Milling Machining:

- Starting the CNC Machine: The machine will perform machining based on the programmed codes, controlling the cutting tool to move along the axes (X, Y, Z) for cutting and shaping the product.

- Material Cutting: The machine removes excess material from the workpiece in small layers, creating the desired shape and size according to the original design.

- During this process, coolant is often used to reduce temperature, extend the lifespan of the cutting tool, and ensure a smooth machined surface.

- Product Inspection and Finishing:

- After machining, the product is inspected for dimensions and shapes using measurement tools to ensure compliance with technical standards. If necessary, the product undergoes finishing processes such as polishing, heat treatment, plating, or painting to enhance durability and aesthetics.

- A comprehensive quality check is performed before delivery.

- CNC Machine Maintenance:

- After machining is complete, regular maintenance for the CNC machine is required, such as cleaning, checking cutting tools, and inspecting the control system to ensure the machine operates smoothly and maintains high performance for future machining tasks.

The CNC milling machining process ensures precision, efficiency, and the ability to produce in bulk, meeting the high technical demands of the mechanical engineering industry.

Viet Son Mechanical is one of the leading experts in CNC milling machining. We are known for our precise machining services, ensuring high technical standards and utilizing modern technology in our production process.

Contact for CNC Milling Machining:

Phone: 0922 668 868

Website: https://vietson.com.vn/

Email: [email protected]

IV. Advantages of CNC Milling Machining

CNC milling machining is a modern technology in the mechanical manufacturing industry, allowing for the production of complex components with high precision and superior productivity. This technology offers several outstanding advantages, making it increasingly popular in production.

High Precision: CNC milling machining provides high accuracy, enabling the production of components with complex sizes and shapes while maintaining minimal tolerances. This is crucial in industries that demand stringent precision, such as aerospace, medical, and electronics.

Automation: CNC milling machines operate automatically, minimizing human intervention during the machining process. This not only increases productivity but also reduces errors caused by human factors.

Time Efficiency: The automated and rapid machining process saves production time. CNC machines can manufacture multiple components in a shorter period compared to traditional methods.

Complex Machining Capability: With flexible programming capabilities, CNC milling machines can create complex shapes that are difficult to achieve with manual machining methods.

Cost Savings: Although the initial investment cost for CNC machines may be high, the savings in time, materials, and reduced errors contribute to lower overall production costs.

Material Versatility: CNC milling machining can be applied to a variety of materials, from metals (such as steel and aluminum) to plastics and alloys, providing flexibility for manufacturers.

Easy Customization and Adjustment: When design changes are needed, reprogramming the CNC milling machine is relatively easy and quick, allowing production to adjust to customer or market demands.

Quality Control: The CNC machining process allows for better monitoring and quality control. Measurement tools can be integrated into the process to ensure products meet technical standards.

Safety and Convenience: Reducing human intervention in the machining process not only enhances product quality but also ensures the safety of operators.

These advantages have made CNC milling machining a popular and effective choice in the manufacturing and production industry.

V. Applications of CNC Milling Machining in Industry

CNC milling machining has become a standard processing method widely applied across various industries due to its flexibility, high precision, and ability to efficiently handle complex components.

Automotive Industry: Manufacturing parts such as frames, shafts, and other mechanical components with high precision to ensure vehicle safety and performance.

Aerospace Industry: Machining complex parts for engines and aircraft structures, where extreme precision and durability are essential.

Medical Industry: Producing medical devices such as bone frames, surgical instruments, and components of medical machinery with absolute precision to ensure patient safety.

Electronics Industry: Machining electronic components, circuit boards, and enclosures with complex shapes and high technical requirements.

Mold Manufacturing: Producing molds for plastic, metal, and other materials, with the precision necessary for mass production processes.

Precision Engineering: Machining precise mechanical components for machinery, equipment, and other industrial applications.

Interior Decoration: Manufacturing decorative components, furniture, and wooden items with intricate designs.

Energy Sector: Machining parts for wind and solar power plants and other renewable energy equipment.

Handicrafts: Creating unique handicraft products with the assistance of CNC technology, providing high aesthetics and quality.

Food Industry: Machining equipment and tools in food processing, ensuring hygiene and food safety standards.

Thanks to these diverse applications, CNC milling machining has become an indispensable part of many modern manufacturing and fabrication sectors.

Viet Son Mechanical specializes in providing CNC milling machining services with a variety of applications across different industries.

Contact for CNC Milling Machining:

Phone: 0922 668 868

Website: https://vietson.com.vn/

Email: [email protected]

VI. Factors Affecting the Quality of CNC Milling Machining

The quality of CNC milling machining is influenced by several factors:

Material Quality: The properties of the material (hardness, strength, ductility) affect the cutting ability and precision of the final product. Different materials require different machining parameters.

Cutting Tools: The quality, shape, and sharpness of the cutting tools are crucial. Worn or inappropriate tools can lead to errors and unsatisfactory surface finishes.

Spindle Speed and Feed Rate: The spindle speed and the cutting tool’s feed rate need to be adjusted according to the material and tool type. Incorrect speeds can lead to overheating, rapid wear, or poor surface finish.

Machining Equipment: The accuracy and stability of the CNC milling machine significantly impact product quality. Old or poorly maintained machines can cause errors during machining.

Control System Accuracy: The programming software and CNC control system need precise calibration. Errors in commands or programming can result in cutting discrepancies.

Workpiece Setup: Properly securing the workpiece on the machine bed is critical. The workpiece must be securely fastened to prevent movement during machining, which affects precision and product quality.

Coolant Usage: Using the appropriate coolant helps lower temperatures during machining, extends tool life, and ensures a smooth surface finish.

Quality Control: Implementing quality checks at each machining stage helps detect issues early and allows for timely adjustments, enhancing the quality of the final product.

These factors must be managed and optimized to ensure product quality in CNC milling machining, effectively meeting customer requirements and technical standards.

VII. How to Choose a Reliable CNC Milling Machining Service Provider

When selecting a reputable CNC milling machining service provider, there are several important factors to consider to ensure that businesses find a partner that meets their needs.

- Experience and Reputation: Research the company’s history and evaluate its reputation through customer feedback and reviews.

- Service Quality: Check the quality control processes and any international certifications that the company holds.

- Technology and Equipment: Assess the types of machinery, technology, and material processing capabilities of the provider.

- Technical Team: Learn about the qualifications and experience of the technical staff, as well as their ability to provide technical advice.

- Customer Service: Ensure that the provider has a good customer service policy and offers prompt support during transactions.

- Delivery Times: Consider the provider’s ability to meet delivery schedules while maintaining quality.

By taking these factors into account, you can find a reliable and quality CNC milling machining service provider that best meets your production requirements.

If you are in need of a reputable CNC milling service provider, Viet Son Mechanical is one of the top choices. Viet Son is recognized for its high-quality CNC gear machining services, supporting the industrial sector in Vietnam and exporting to many countries worldwide.

Some highlights of Viet Son Mechanical:

- Highly Skilled Technicians: Our team possesses strong expertise and experience in CNC machining.

- Modern Equipment: We utilize advanced CNC milling machines to ensure high precision and machining efficiency.

- Dedicated Customer Service: We actively listen and respond to customer needs, providing solutions that optimize costs. Our delivery and after-sales service are handled professionally.

- Guaranteed Product Quality: All products undergo thorough inspection before delivery to customers.

By integrating advanced technology and creativity into our production process, Viet Son not only produces mechanical products that meet international standards but also sets trends in the industry. We also offer customized machining services to meet specific production needs.

Contact for CNC Milling Machining:

- Phone: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website: https://vietson.com.vn/

- Email: [email protected]

- Facebook: Viet Son Mechanical Facebook

- YouTube: Viet Son Mechanical YouTube Channel

Viet Son is always ready to listen and provide the best services and products to meet all customer needs. For more detailed information, please feel free to contact us!