1. Introduction: The demand for CNC machining in the era of Industry 4.0

As production speed and efficiency become increasingly demanding, manufacturing businesses must adopt advanced technologies to ensure product quality and optimize production costs. One of the most widely applied technologies today is CNC Milling.

In Vietnam, Viet Son Mechanical is a pioneer in the field of precision mechanical processing, especially CNC Milling, with a team of experienced technicians and a modern machinery system. With the motto “Precision – Sustainability – Dedication”, Viet Son Mechanical is always the top choice for both domestic and international enterprises when it comes to machining highly technical components.

2. What is CNC Milling?

CNC Milling (Computer Numerical Control Milling) is a precision machining method where material is cut and shaped using a milling machine controlled automatically through computer programming.

Unlike traditional milling methods, CNC Milling uses encoded programs (G-code) to control tool movements, spindle rotation, speed, cutting depth, and milling paths. This ensures absolute precision and high repeatability for both mass and single-piece production.

Advantages of CNC Milling over conventional milling:

- Precisely controls each detail with extremely low tolerance (under 0.01mm).

- High processing speed, reducing production time.

- Capable of machining complex 3D profiles or tight-tolerance components.

- Flexible in design changes.

- Minimizes human error and reduces waste.

3. Applications of CNC Milling in industrial production

Thanks to its high precision and ability to process a wide range of materials, CNC Milling is widely used in many industries:

a. Machinery manufacturing

CNC Milling is indispensable in producing machine parts, mechanical assemblies, and industrial machinery like packaging machines, presses, CNC machines, and more.

b. Mold making industry

In mold making (plastic molds, metal casting molds, rubber molds…), CNC Milling helps create complex contours with high accuracy and smooth surfaces, minimizing the need for polishing.

c. Automotive – motorcycle – aerospace

Components like pistons, engine blocks, camshafts, gears, and gear housings are all machined using CNC Milling to ensure durability and reliable performance.

d. Electrical – electronics

Enclosures, mechanical PCBs, and stamping molds for electronics are all produced using CNC Milling for precision.

e. Construction and civil mechanical works

Steel structure parts, brackets, railings, bolts, and supports—all require CNC Milling to optimize installation performance and product durability.

4. The importance of CNC Milling in modern manufacturing

In the context of economic integration and increasingly stringent product quality requirements, CNC Milling is not just a machining method—it is a vital factor for manufacturing enterprises to thrive.

Benefits that CNC Milling offers:

- Increased precision and reliability: Extremely small tolerances, uniform products.

- Higher productivity: Fast milling speed, suitable for mass production.

- Cost-saving on labor and materials: Fewer errors and less waste.

- Meets high technical demands: Machining complex shapes and hard materials.

- Eco-friendly: Less dust, noise, and supports coolant recycling systems.

Investing in CNC Milling technology is therefore an investment in sustainable growth.

5. CNC Milling process at Viet Son Mechanical

At Viet Son Mechanical, the CNC Milling process is standardized into the following steps:

Step 1: Technical requirement intake

Customers provide technical drawings, product samples, or detailed specifications. Our engineers will consult and propose the most optimal solution.

Step 2: CAD/CAM design and programming

Using CAD/CAM software like SolidWorks, MasterCAM, and NX, we design 3D models and generate CNC machining programs (G-code).

Step 3: Machine preparation and workpiece setup

The workpiece is securely clamped on the machine table and aligned precisely with the machine’s coordinate system to ensure vibration-free milling.

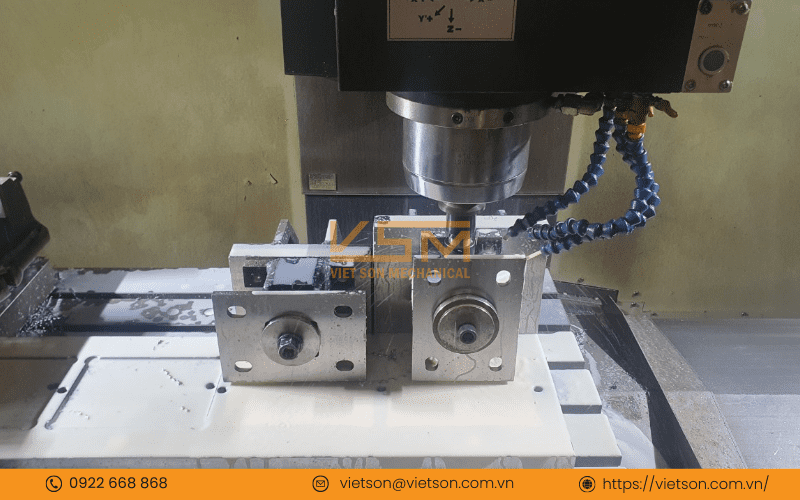

Step 4: CNC machining execution

The program is run automatically. Technicians monitor the operation closely to ensure safety and precision.

Step 5: Quality inspection and measurement

After completion, the product is measured using calipers, micrometers, and CMMs to ensure dimensional and tolerance compliance.

Step 6: Product delivery

Finished products are packaged and delivered to the customer in accordance with specifications and deadlines.

6. Common CNC Milling operations today

CNC Milling includes many different operations based on technical requirements:

- Face milling: For machining flat or angled surfaces.

- Groove milling: Creating keyways, circular or square slots.

- 3D surface milling: For molds and complex curved surfaces.

- Hole milling and drilling: Integrated in one setup.

- Multi-axis milling: Using 4-axis or 5-axis machines for special profiles.

Depending on the product, Viet Son Mechanical will select the most suitable machine and milling strategy to ensure optimal quality and cost.

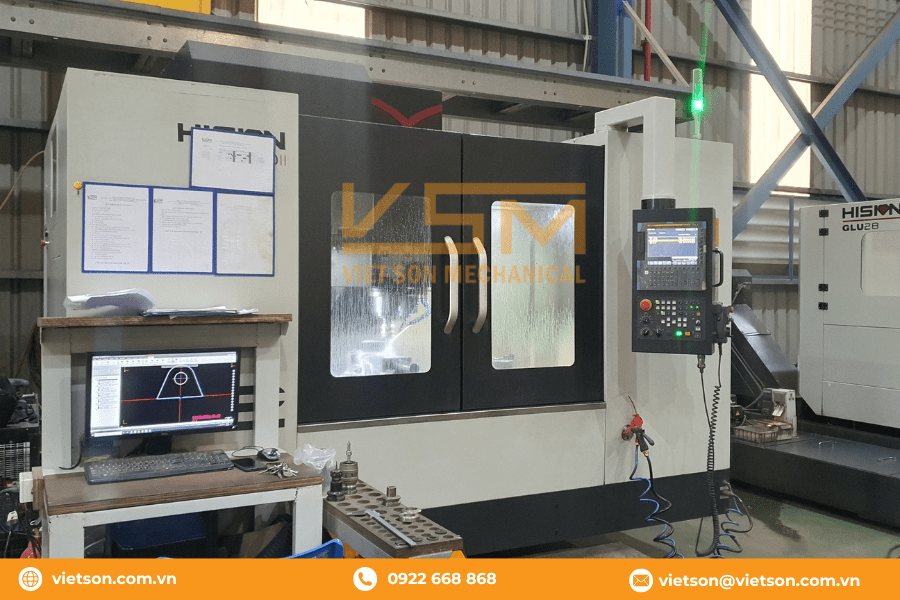

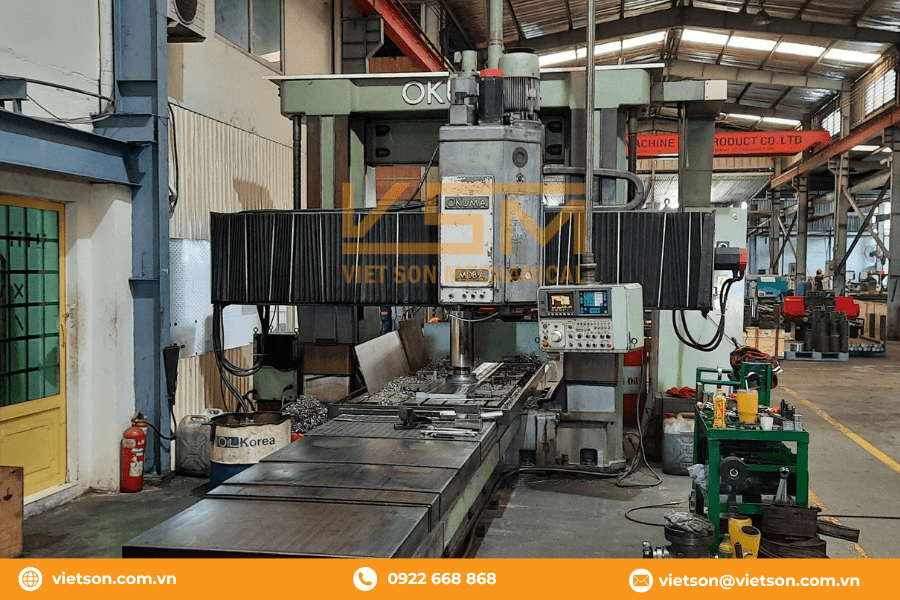

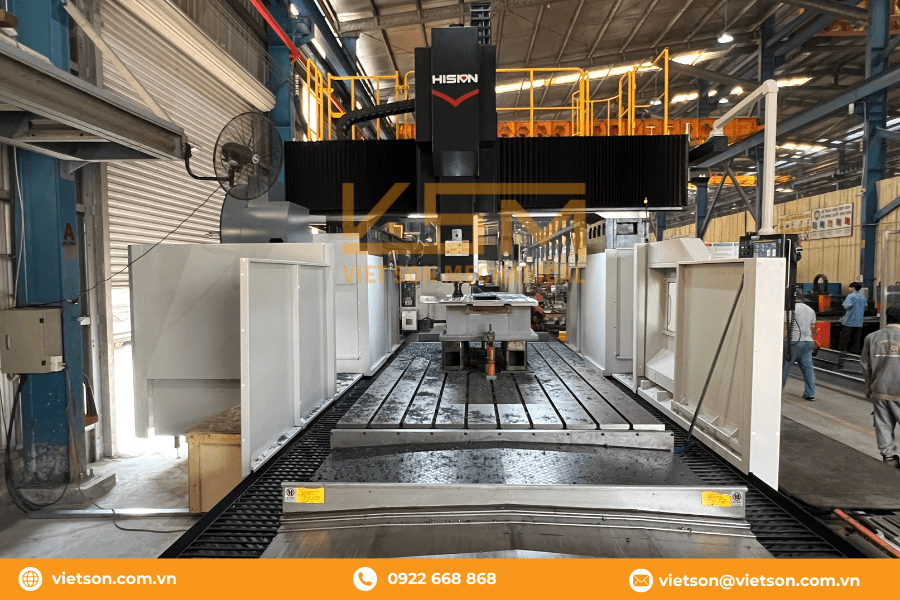

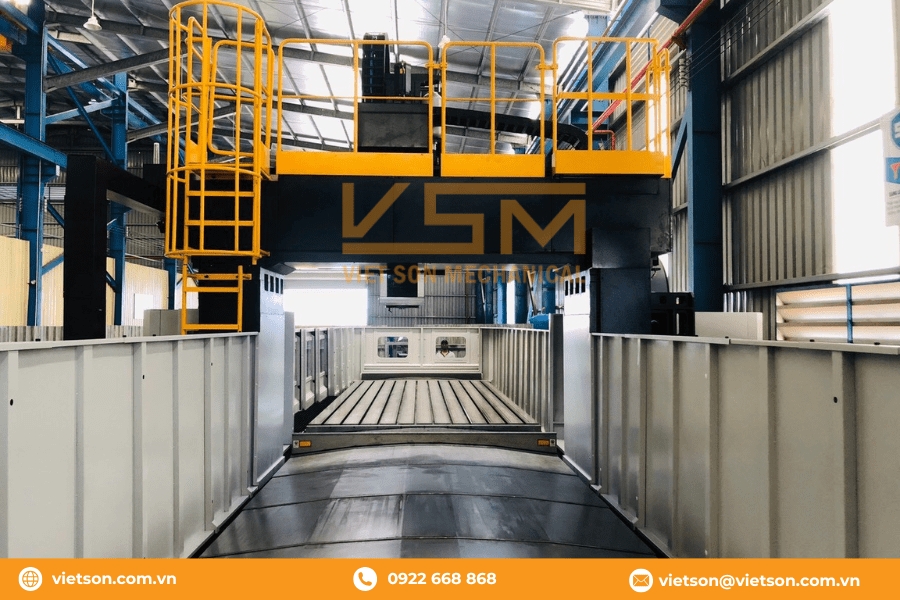

7. Modern machining equipment at Viet Son Mechanical

Việt Sơn Mechanical owns a modern fleet of milling machines, supporting a wide range of products from small to oversized components:

- CNC Milling machine 1.2m: Ideal for small, high-precision parts used in precision mechanics.

- Gantry milling machine 3m: Suitable for medium-sized structures such as rails or shafts.

- Gantry milling machine 4m: Serves industrial equipment components and medium structural steel.

- Gantry milling machine 6.5m: Specialized for oversized parts such as machine frames, machine bases, and crane structure components.

All machines are routinely maintained, fully CNC-controlled, and paired with the latest CAM software to ensure powerful and accurate machining capabilities.

8. How much does CNC Milling cost?

The cost of CNC Milling depends on several factors:

- Size and complexity of the part.

- Material type: Steel, stainless steel, aluminum, copper, technical plastics…

- Tolerance level: The smaller the tolerance, the higher the cost.

- Order quantity: Bulk orders receive better pricing.

- Surface finish requirements: Grinding, polishing, plating…

At Viet Son Mechanical, we commit to:

- Transparent quotations for each processing item.

- The most competitive pricing in the market, especially for loyal customers or long-term contracts.

- No hidden fees, no unexpected price increases.

Customers are encouraged to send us technical drawings or specifications to receive a free detailed quotation.

9. Viet Son Mechanical – A trusted CNC Milling service provider

With over 15 years of experience in precision mechanical processing, Viet Son Mechanical proudly partners with many domestic and international enterprises in manufacturing, construction, mold-making, and automation.

Why choose Viet Son Mechanical?

- Long-standing experience, highly skilled engineers and technicians.

- Modern equipment, capable of machining everything from small to oversized parts.

- Strict processes, comprehensive quality control.

- On-time delivery, flexible scheduling for project demands.

- In-depth technical consultation, assisting with product design and optimization.

Contact Us

- Factory Address: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City, Vietnam

- Office Address: 253 Dien Bien Phu Street, Xuan Hoa Ward, Ho Chi Minh City, Vietnam

- Hotline: (+84) 922 668 868 (Available on Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn

- Email: [email protected]

- Facebook: Cơ khí Việt Sơn

- YouTube: youtube.com/cokhivietson