Overview of Modern Construction Trends

With climate change becoming more severe and the cost of building materials and labor continuously rising, the global construction industry is undergoing a major transformation to seek more optimal, economical, and sustainable solutions. Among them, the LIGHT GAUGE STEEL HOUSE has emerged as an inevitable trend of the era.

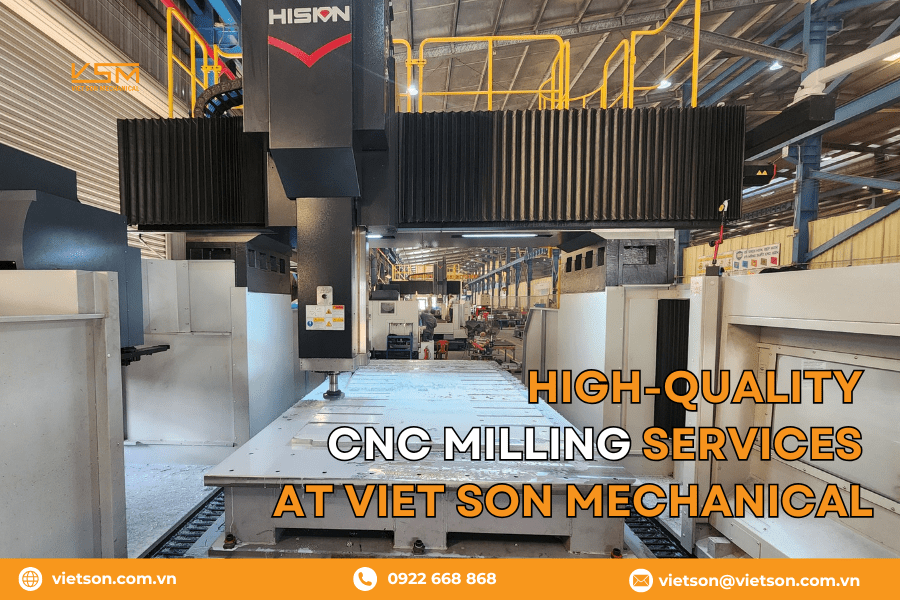

Originally used for temporary shelters like worker camps or field offices, LIGHT GAUGE STEEL HOUSES are now widely applied in factories, schools, offices, homestays, residential buildings, and other specialized structures. With over 15 years of experience in the mechanical engineering industry, Viet Son Mechanical is proud to be a pioneer in delivering high-quality LIGHT GAUGE STEEL HOUSE solutions, applying advanced manufacturing technologies that meet international standards.

What is a LIGHT GAUGE STEEL HOUSE?

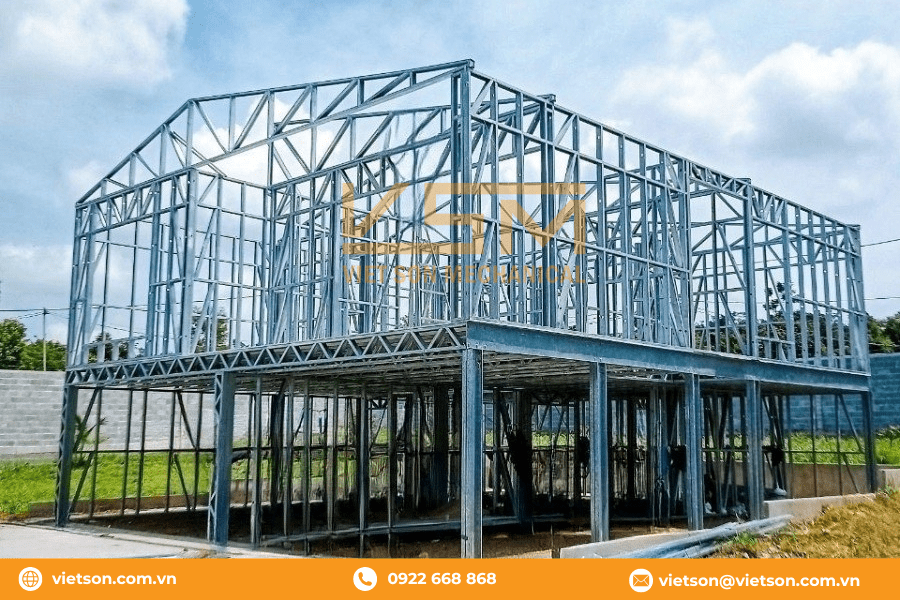

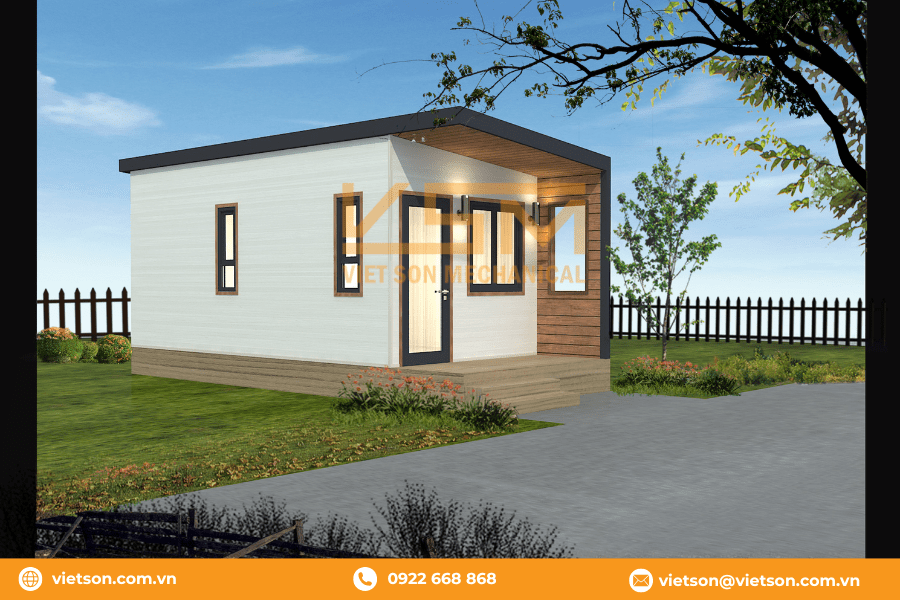

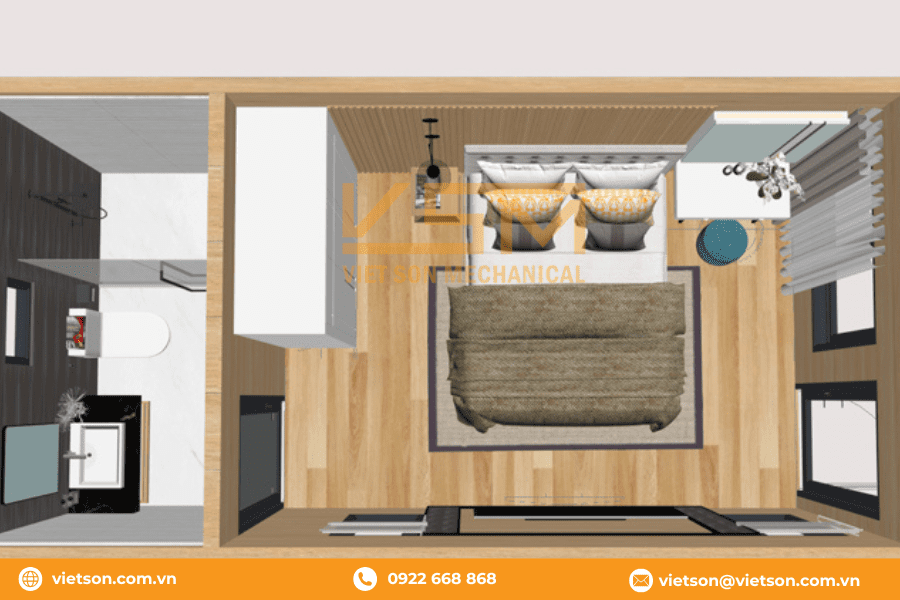

A LIGHT GAUGE STEEL HOUSE is a building model that uses prefabricated components manufactured at the factory and assembled directly on site. The main structural frame is typically made from lightweight steel, insulated panels, and EPS or cement board wall panels. Components such as columns, beams, purlins, walls, and roofs are all pre-designed to standard specifications and can be easily assembled or dismantled.

Outstanding Advantages of Using Light Steel Frame Houses

1. Fast Construction, Time-Saving

- Saves 50–70% of construction time.

- Quick installation with only 3–5 construction workers.

2. Cost-Effective Investment

- Minimizes labor needs and reduces site rental duration.

- Optimizes long-term operational costs.

3. Easy to Dismantle, Reuse, and Relocate

- Up to 90% of frame materials can be reused.

- Reduces construction waste, saves long-term investment.

4. Safe – Durable – Aesthetic

- Resistant to termites, high load-bearing capacity, no cracks.

- Diverse designs and modern color schemes.

5. Environmentally Friendly

- Aligns with green building trends and resource-saving goals.

- Reduces CO₂ emissions and meets LEED standards (Leadership in Energy and Environmental Design).

Call us now: +84 922 668 868 Email: [email protected] Website: www.vietson.com.vn

Applications of Light Gauge Steel House

Thanks to their superior durability, load-bearing capacity, and quick construction, steel frame structures are widely applied in various sectors:

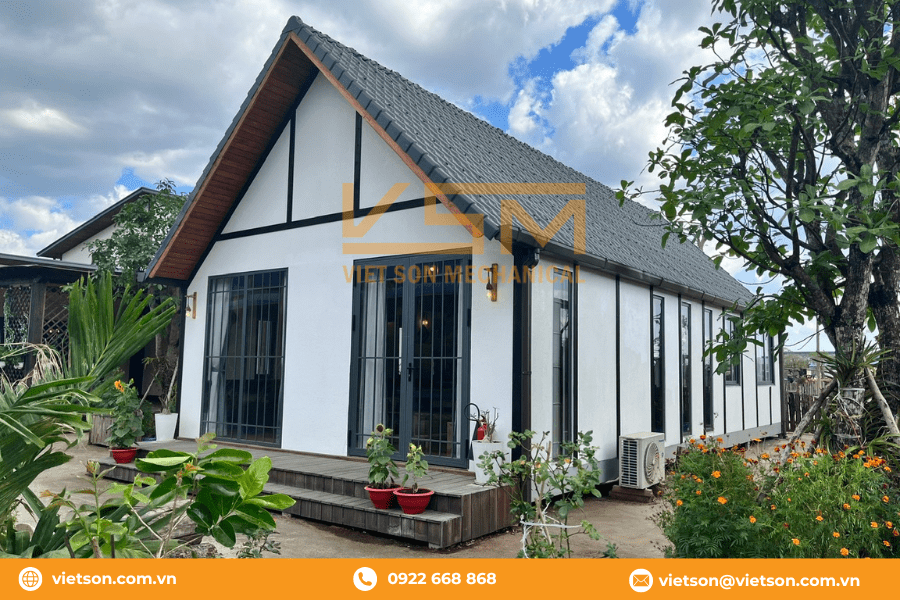

1. Residential

- Modern and durable steel-frame townhouses and villas.

- Budget-friendly LGSF single-story homes with fast installation.

- Compact prefabricated houses for families or homestays.

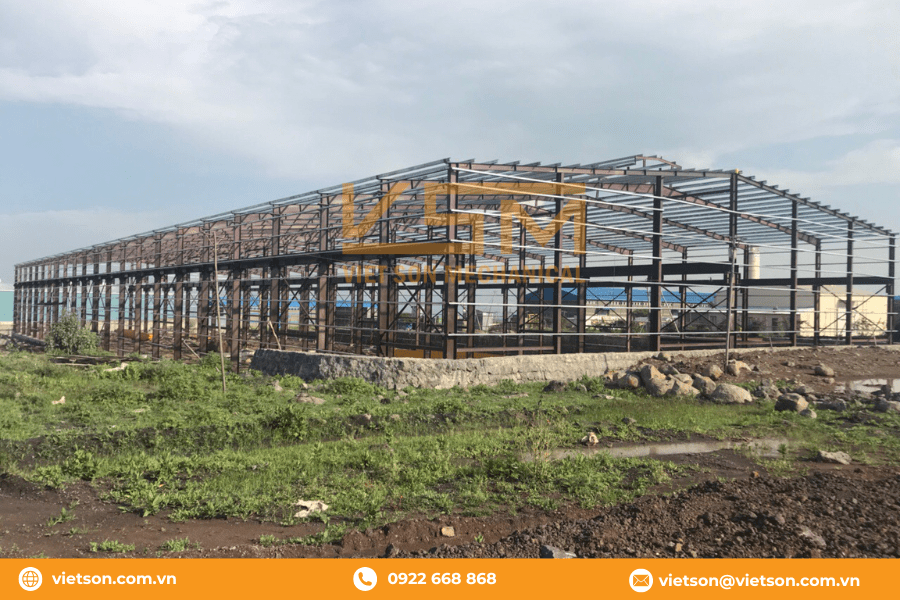

2. Industrial Projects

- Factories, warehouses, and industrial zones.

- Manufacturing and assembly plants.

- Cold storage and heavy-load warehouse facilities.

3. Commercial Projects

- Automotive and industrial machinery showrooms.

- Shopping malls, supermarkets, and convenience stores.

- Restaurants and cafes with modern design.

4. Public Infrastructure

- Community centers, sports arenas.

- Bus shelters, waiting stations, terminals.

- Conference and exhibition centers.

LIGHT GAUGE STEEL HOUSE Services by Viet Son Mechanical

As a leading enterprise in mechanical construction and steel structures in Vietnam, Viet Son Mechanical continuously innovates and develops to provide a comprehensive LIGHT GAUGE STEEL HOUSE solution, meeting the increasingly diverse and flexible needs of today’s construction market. We offer an end-to-end service from design consulting, steel fabrication, on-site installation, to final handover – helping customers save time, optimize costs, and ensure long-lasting quality.

With more than 15 years of practical experience in mechanical manufacturing and industrial construction, along with a highly skilled engineering team and modern factories in Ho Chi Minh City, Viet Son Mechanical has firmly established its position in the market. We are proud to be the trusted partner of hundreds of domestic and international clients, participating in thousands of projects across Vietnam and Southeast Asia.

LIGHT GAUGE STEEL HOUSE Installation Process at Viet Son Mechanical

Step 1: Customer Order

- Requirement gathering: Receive project details including type, scale, and specific technical needs.

- Solution consulting: Engineers offer initial suggestions on construction methods, steel frame structure, and material options.

- Contract signing: Formal agreement after discussing all design and construction terms.

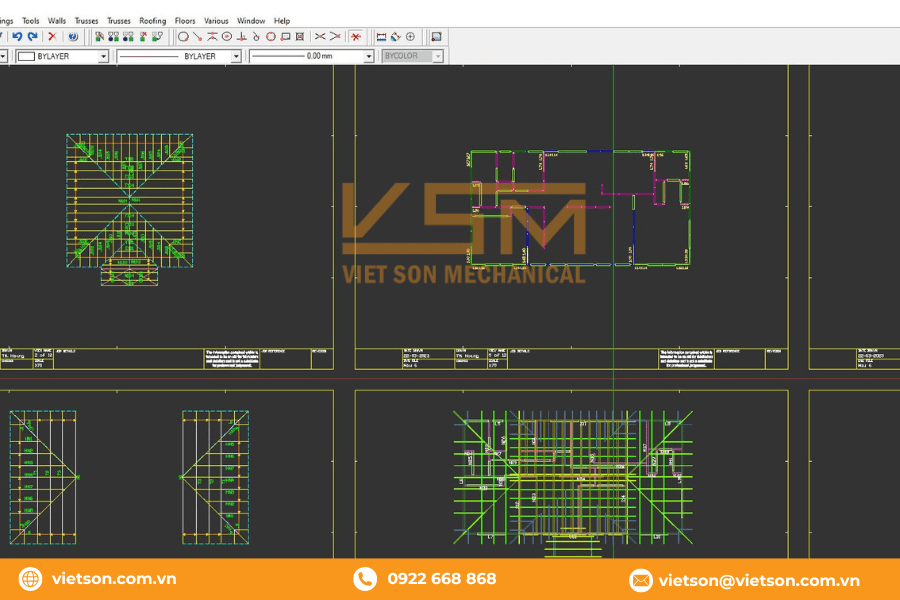

Step 2: Design Software

- Professional software such as PROCAD, 3DS MAX, and AutoCAD is used to create 3D models and 2D technical drawings.

Step 3: 3D Models, 2D Drawings, BOM, Quotation, CNC Data

- 3D Models: Provide a visual overview of the entire steel frame structure.

- 2D Drawings: Include floor plans, elevations, sections, and connection details.

- Bill of Materials (BOM): List all required materials such as:

- Main steel frame: columns, beams, purlins.

- Walls and roofs: roofing sheets, insulated panels.

- Accessories: bolts, screws, anti-rust paint.

- Quotation: Estimate costs for materials, labor, equipment, and timeline.

- CNC Data: Export data for CNC programming to ensure high-precision manufacturing.

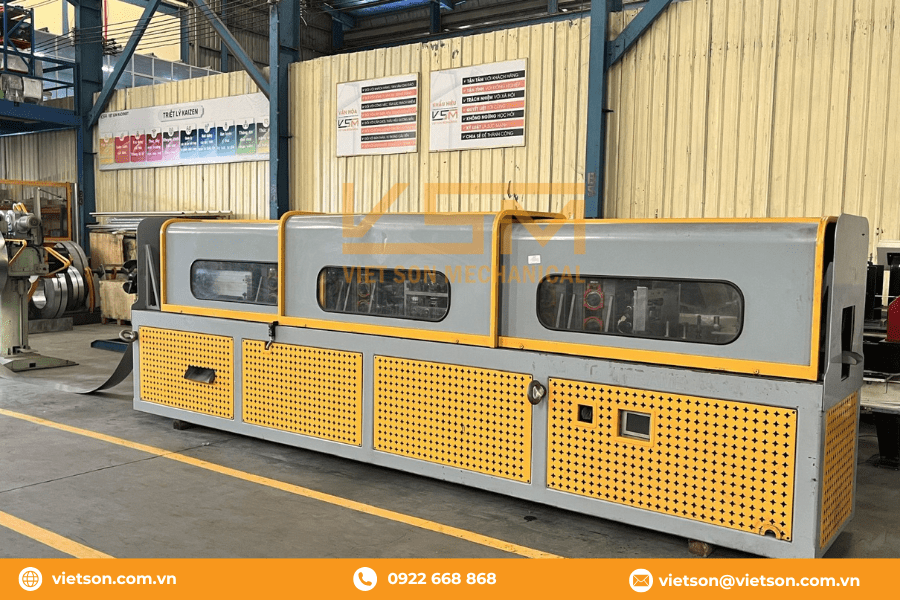

Step 4: SmartFrame Machine for Steel Frame Fabrication

- SmartFrame machines automatically cut, punch, and form steel components based on the design.

- CNC technology ensures high precision in every detail.

- All components of the frame, walls, and roof are fully automated and produced on the SmartFrame system.

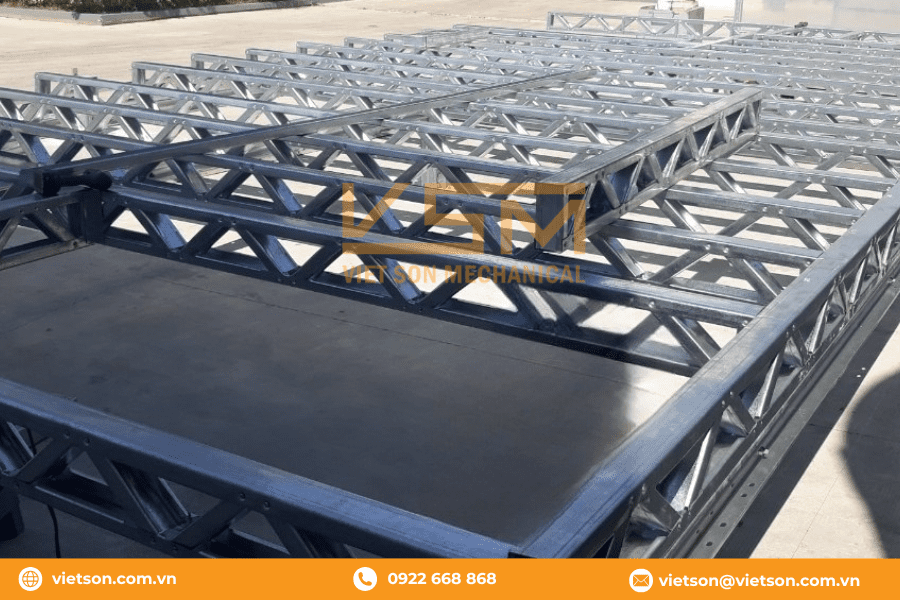

Step 5: Products

- Completed steel frame components are inspected for size, welding quality, and accuracy.

- Coated with anti-rust paint and carefully packaged for transportation.

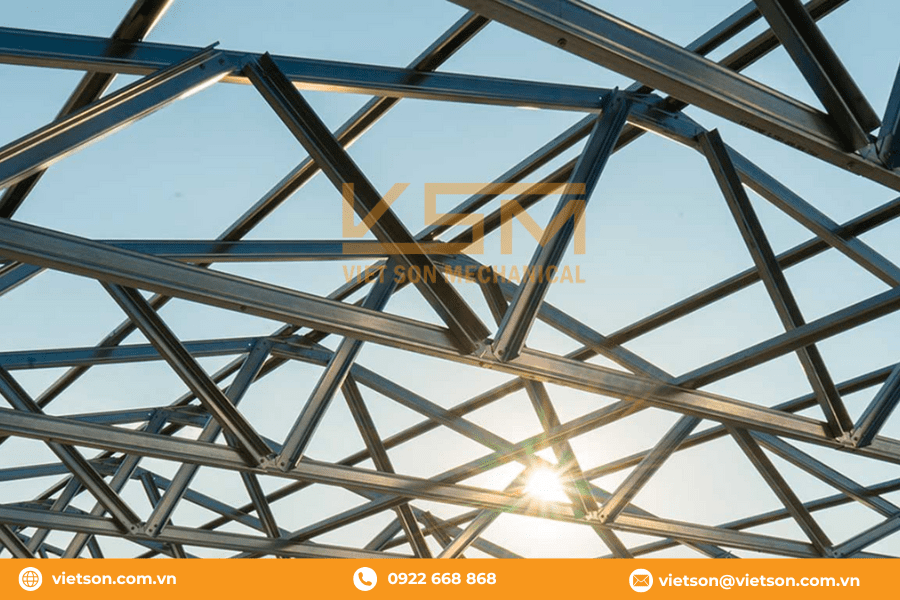

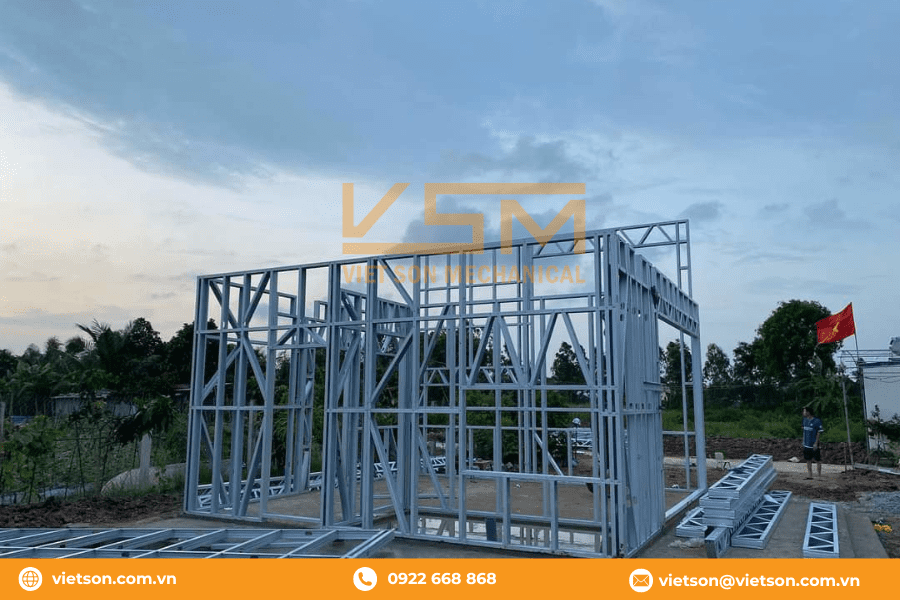

Step 6: Assembly of Floor | Wall | Roof Frame

- Roof frame structure

- Wall frame structure

- Floor frame structure

Step 7: Complete Steel House Frame

- Final assembly: The steel frame is assembled according to the installation drawings, ensuring accuracy and vertical alignment.

- Reinforcing connections: Use high-strength bolts and bracing systems to enhance stability.

- Inspection and acceptance: Evaluate the strength, roof tightness, and frame alignment.

Viet Son Mechanical Brings LIGHT GAUGE STEEL HOUSE to Sydney Build Expo 2025

We are proud to showcase our LIGHT GAUGE STEEL HOUSE – a sustainable and flexible construction solution – at Sydney Build Expo 2025, taking place on May 7–8, 2025 at ICC Sydney – Booth 10, Hall 4.

This is a golden opportunity for customers, investors, and international partners to directly experience:

- Steel frame components produced by SmartFrame machines.

- Full mock-ups of our LIGHT GAUGE STEEL HOUSE solutions.

- On-site technical consultation, design solutions, and quotations.

A LIGHT GAUGE STEEL HOUSE is not just a trend – it is the inevitable solution for a modern construction world: fast, adaptable, and sustainable. With industry-leading production capabilities, advanced technology, and a dedicated technical team, Viet Son Mechanical is committed to delivering the most optimal LIGHT GAUGE STEEL HOUSE solutions for every usage scenario.

Wellcome to Booth10, Hall 4!

Contact Viet Son Mechanical Today!

- Factory: Lot C2-7, Street N7, Tan Phu Trung Industrial Zone, Cu Chi, Ho Chi Minh City, Vietnam

- Office: 253 Dien Bien Phu St., Vo Thi Sau Ward, District 3, Ho Chi Minh City, Vietnam

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson?locale=vi_VN

- YouTube: youtube.com/cokhivietson