Light gauge steel is a construction material that has gained increasing popularity in recent years due to its many advantages over traditional building materials. Light gauge steel is made from thin sheets of steel that are bent and formed into various shapes, resulting in a lightweight yet durable material that is easy to handle and transport.

What is light gauge steel?

Light gauge steel (LGS) is a construction material made from thin sheets of cold-formed steel. The steel sheets are usually less than 3mm thick. It is used in the building industry as purlins girts, light struts, roof sheeting, and floor decking,…

Light gauge steel is a popular construction material that offers some benefits over traditional building materials.

Nowadays, LGS is becoming increasingly popular in residential, industrial, and commercial buildings. Especially, in pre-engineered steel buildings.

The main components of light gauge steel frame

Wall system

A load-bearing wall carries vertical loads from the construction above or lateral loads resulting from the wind. These loads may act separately or in combination. Wall cladding refers to the outer layer of the wall system that provides weather protection and aesthetic appeal. Partitions are internal walls that divide a space into separate rooms or areas.

Flooring system

The flooring system in a light gauge steel frame can be made up of C-sections as joists connected to C-section bearers. The floor joists can be designed from a range of C-section sizes depending on loading parameters such as the weight of the flooring material, live loads from occupants or furniture, and any additional point loads from equipment.

Roof system

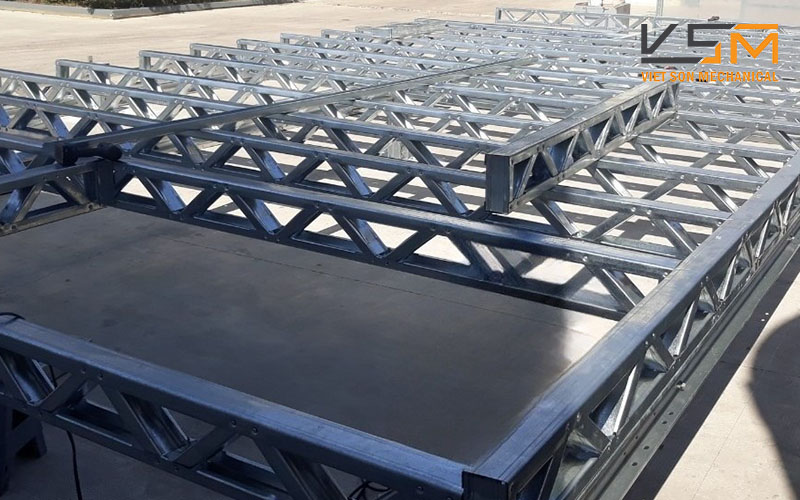

The roof system in a light gauge steel frame is typically a steel truss system that can be designed to support metal sheets or tiles. The steel roof framing system can suit all types of roof designs, including hip, gable, and Dutch gable roofs.

Advantages of light gauge steel

Here are 7 main advantages of LGS construction:

Lightweight and durable

Light gauge steel is lightweight, making it easy to handle and transport to the construction site. Despite its lightweight, it is incredibly durable and can withstand extreme weather conditions such as high winds, heavy snow loads, and earthquakes.

High strength

Light gauge steel has a high strength-to-weight ratio and is strong enough to support a large load while being lighter than timber and concrete. This makes it an ideal material for constructing buildings that require large spans or high-rise structures.

Structural safety

Light gauge steel’s strength and noncombustible properties enable it to withstand fires, earthquakes, and hurricanes.

Speedy construction

Light gauge steel structures can be assembled quickly and efficiently, reducing construction time. The components are pre-engineered and can be easily transported to the construction site. Overall saves up to 30% of the time for a project.

Design flexibility

Light gauge steel can be easily customized to fit any architectural style or design. The steel components can be cut and shaped to fit the exact specifications of the building design.

Remodel easily

Light gauge steel structures can be easily modified or remodeled to accommodate changing needs. The components can be disassembled and reassembled without causing damage, making adding or removing walls or modifying the building layout easy.

Recyclable

Light gauge steel is 100% recyclable, making it an environmentally friendly building material.

The applications of light gauge steel

Light gauge steel is a versatile building material that can be used in a variety of applications. Some of the standard applications of light gauge steel include:

- Villas, Residential houses, Apartments

- Warehouses, Sheds, Temporary Storage

- Commercial Office Complexes

- Low-Cost Houses

- Showrooms with composite Hot Rolled Frames

- School, Hospital Partition Walls, Cabins

- Portable Site Offices, Portable Toilets

Light gauge steel house construction price list

Viet Son provides a quote for the complete coverage of the assembled house, which is approximately 8.5 million VND per square meter, based on the proposed coverage configuration, including:

- Roof: simulated tile plastic-coated sheet

- Ceiling: 16mm PU insulated sheet

- Inner wall: 9mm Cemboard – Korean wallpaper

- Outer wall: 9mm Cemboard – 8mm Thai wood-grain coated Cemboard

- Bathroom: wall tiled

- Door: Tungshin aluminum with 5mm tempered glass

- Standard sanitary equipment: Vilarcera toilet and washbasin, Binh Minh water pipes

Viet Son – A reputable light gauge steel house construction company

Viet Son Mechanical is one of the leading companies in the field of designing and constructing light gauge steel houses.

Viet Son’s LightFrame light gauge steel houses meet the following criteria:

- Comprehensive solution: the entire process from design and manufacturing to completion of the house is completed and synchronized.

- Cost-effective: the light gauge steel houses are calculated and designed to be the most optimal.

- Rapid solution: all components are carefully manufactured with high-quality materials in the factory and quickly assembled on-site. The time to complete a prefabricated house is only 1/3 of the time required for a traditional house.

- Top quality: Viet Son understands that quality is a prerequisite for success, and produces high-quality products in modern factories with strict quality management processes.

- Global application: Viet Son’s light gauge steel houses are favored by most developed countries, and the company can design according to the customer’s needs, from resort villas to high-end apartments.

- Innovation: by combining advanced technical expertise in pre-engineered steel and super lightweight steel prefabricated house fields, Viet Son achieves high efficiency and load-bearing capacity, resulting in outstanding performance.

- Flexible and convenient design: combining the functional and financial factors of the project site, the existing structures are utilized and interior furnishings are arranged to create a comfortable and relaxing space.

- Environmentally friendly: all projects are harmoniously combined with natural lighting and ventilation. Natural materials found in coastal areas are used, and recycled materials are utilized, making the solution green and eco-friendly.

- Product longevity: the light gauge steel houses have a lifespan of about 30 years and can withstand wind speeds of up to category 12 hurricanes. Viet Son will provide maintenance and repair services for your house.

Choose Viet Son Mechanical to have a smart housing solution.

Here are some light gauge steel house models executed by Viet Son

Contact Viet Son for accurate advice and quotation on LightFrame light gauge steel houses:

- Hotline: +84898 679797 | +84922668868

- Email: [email protected]

- Fanpage: Viet Son Mechanical

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Cu Chi District, Ho Chi Minh City, Vietnam.