I. Overview of the mechanical engineering industry in the region.

The Mechanical Processing in Tan Binh is a dynamic and developing field, playing an important role in the economy of Ho Chi Minh City. This area is home to many factories, enterprises, and production facilities, creating a diverse ecosystem for the mechanical engineering industry.

1. Characteristics of the mechanical processing industry in Tan Binh

Diverse products: The Mechanical Processing in Tan Binh produces various types of products such as machine components, industrial equipment, household appliances, and mechanical parts for the construction and automotive sectors.

Advanced technology: Many businesses in the region have invested in modern technology and advanced machinery, helping to improve product quality and increase labor productivity.

2. Market and demand

Tan Binh is one of the rapidly developing areas of the city with many industrial zones and industrial clusters. The demand for mechanical processing products and services here is always high due to the development of other industries.

The area also attracts many domestic and foreign investment projects, creating opportunities for the expansion of the mechanical engineering industry.

3. Opportunities and challenges

Opportunity: The transformation of the economy and the high demand for product quality create many opportunities for mechanical processing units. Participating in the global supply chain also brings growth potential.

Challenge: Fierc competition in the mechanical engineering industry requires businesses to continuously improve technology, enhance service quality, and optimize production processes.

The mechanical engineering industry in Tan Binh not only contributes to the local economic development but also plays an important role in providing essential products for the national industry. The sustainable development of this industry will contribute to enhancing Tan Binh’s position in the context of global competition.

II. Popular mechanical machining services in Tan Binh

The Tan Binh area stands out with a variety of mechanical processing services, meeting the needs of different industries.

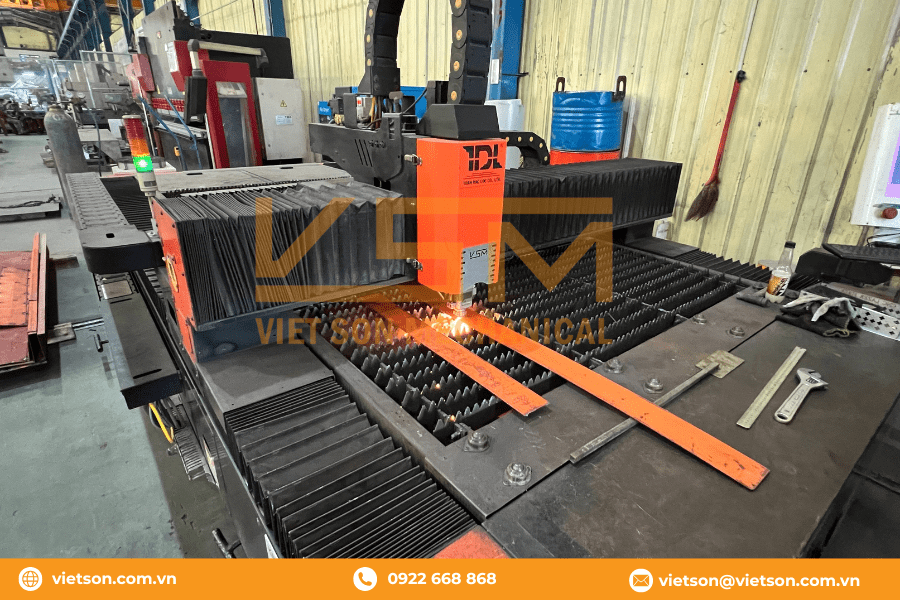

1.Laser cutting processing

Using modern laser cutting technology to create precise shapes and sizes from metal sheets. This is a quick method, resource-efficient, and highly precise.

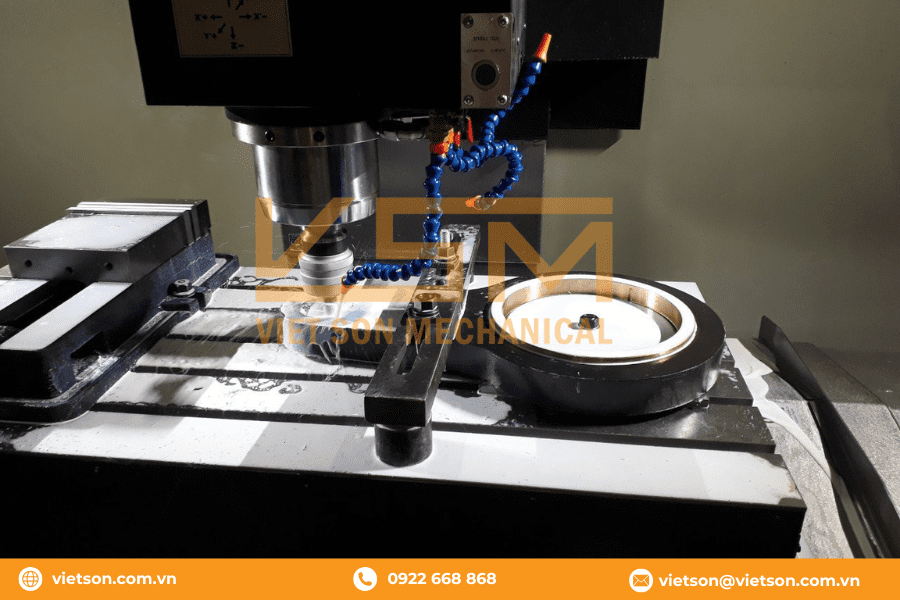

2. CNC milling

CNC milling services allow for the machining of complex-shaped parts. With CNC milling machines, products can be processed with high precision and good working efficiency.

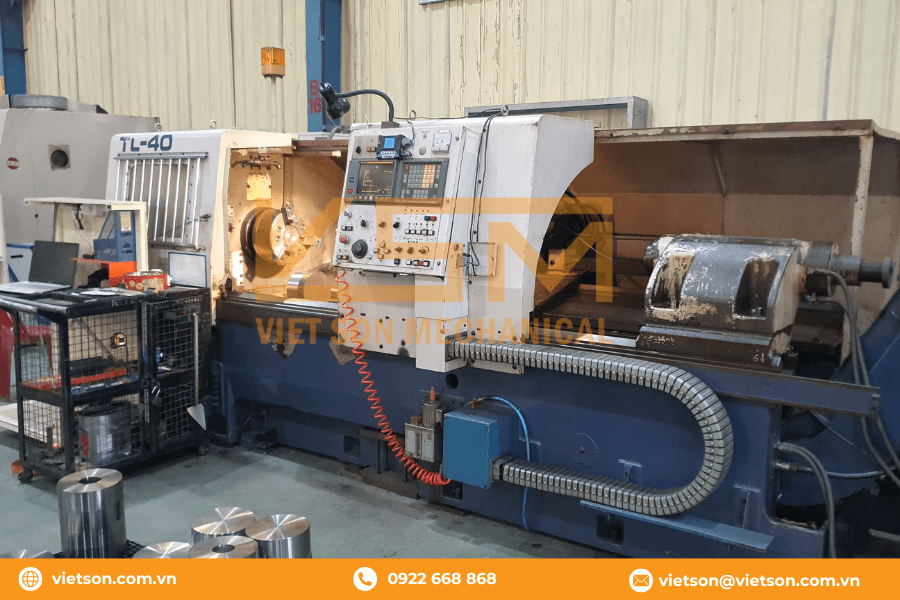

3. CNC turning

CNC turning is used to create round or cylindrical parts with high precision. This service is often applied in the machinery parts manufacturing industry.

4. Surface treatment processing

Surface treatment services such as polishing, plating, powder coating, and anti-rust spraying help enhance the durability and aesthetics of the product.

5. Manufacturing brackets and structural frames

Providing processing services for structural frames, reinforcement for products or construction works. This includes the fabrication of steel structures and iron frames for factories, houses, and other constructions.

6. Manufacturing special components

Tan Binh also has many units that process special mechanical components according to customer requirements, serving industries such as machinery manufacturing, electronics, and automation.

The mechanical machining services in Tan Binh are not only diverse but also ensure quality and professionalism, effectively meeting the needs of customers both within and outside the area. Investment in technology and the enhancement of the technicians’ skills are key factors that help the mechanical processing industry here develop sustainably.

III. Typical Mechanical Processing Company in Tan Binh

Viet Son Mechanical is one of the leading units in the field of mechanical processing in Vietnam, with many years of experience and reputation in the industry. Viet Son Mechanical specializes in providing high-quality mechanical processing services, meeting the diverse needs of customers.

Although Viet Son Mechanical does not belong to the Tan Binh area, with our extensive experience and market reputation, we are confident in meeting the mechanical processing needs of customers in this area.

Main services

- CNC machining: Using modern technology to process complex parts with high precision.

- Profile steel processing: Providing profile steel processing solutions for the construction and manufacturing industries.

- Deck manufacturing: Specializing in the production and processing of high-quality deck floors for construction projects.

Quality commitment

Viet Son Mechanical commits to providing the best products and services with a professional production process, strict quality control, ensuring that all products meet the highest standards.

Professional team

We have a team of experienced engineers and staff, always ready to advise and support customers in every project.

Viet Son Mechanical Company is not only a reliable partner but also a trustworthy companion on your development journey. Please contact us to learn more about our services and products.

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/

- Email: [email protected]

IV. CNC machining process at Viet Son in the Tan Binh area

Viet Son Mechanical Company proudly possesses a professional mechanical processing process, ensuring high product quality and quickly meeting customer needs.

1. Receiving customer requests

- Survey information: Receive requests from customers regarding products that need processing, including dimensions, materials, and specific technical specifications.

- Consultation: Provide information and the best solutions to meet customer requirements.

2. Plan the design

- Designing drawings: Use CAD software to create detailed drawings according to customer requirements.

- Confirmation: Send the drawing to the customer for approval before proceeding with the processing.

3. Choosing ingredients

- Quality ingredients: Choose types of ingredients that meet technical requirements, ensure quality, and have clear origins.

- Inspection: Conduct quality checks on raw materials before they are put into production.

4. Machining

- Cutting, Bending, Welding: Using modern machinery to perform processing steps such as cutting, bending, and welding, ensuring accuracy according to the design drawings.

- CNC machining: For complex parts, use CNC milling and CNC turning to achieve the highest precision.

5. Surface treatment

Surface finishing: Carry out surface treatment processes such as grinding, polishing, or anti-rust painting to enhance the aesthetics and durability of the product.

6. Quality control

- Measurement and evaluation: Use specialized measuring devices to check the size and shape of the product.

- Comprehensive inspection: Evaluate product quality before delivery, ensuring compliance with technical standards.

7. Packing and shipping

- Carefully packaged: The product is safely packaged to protect it during transportation.

- On-time delivery: Arrange delivery according to the time agreed upon with the customer.

The mechanical processing process of Viet Son in the Tan Binh area not only focuses on product quality but also prioritizes customers, ensuring their satisfaction and trust. With experience and investment in technology, Việt Sơn is committed to delivering high-quality mechanical products that meet all market demands.

Above all, Viet Son Mechanical not only excels in the mechanical processing process but also provides reputable and high-quality customer care and after-sales services.

V. Why you should choose machining at Viet Son Mechanical Company

Viet Son Mechanical Company was established with the mission of providing high-quality mechanical processing solutions for various industries. We are proud to be one of the leading units in the field of mechanical processing in Ho Chi Minh City, especially in the Tan Binh area.

Professional team: With a team of highly qualified engineers and technicians with many years of experience in the industry, Viet Son is committed to providing customers with products that meet the highest standards of quality and precision. We always strive to update new technologies and improve production processes to serve our customers in the best way possible.

Diverse services: Viet Son Mechanical offers a variety of mechanical processing services, but still commits to services with modern processes and machinery.

Quality commitment: Viet Son is committed to always using high-quality materials and applying strict quality control processes to ensure that each product meets the highest standards. With a dedicated warranty policy and after-sales service, Việt Sơn is always ready to assist customers with any arising issues.

Diverse customers: Viet Son Mechanical serves a diverse range of customers both domestically and internationally, from large companies to small manufacturing workshops, in fields such as construction, machinery manufacturing, automotive production, and electronics. We always listen to and understand our customers’ needs to provide the best solutions.

With the motto “Viet Son Mechanical – Cooperating for Development” we continuously strive to become a reliable partner in the field of mechanical processing. Please contact us for the best consultation and support for your projects!

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website: https://vietson.com.vn/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson