In modern construction, structural steel plays a crucial role in creating durable structures, optimizing costs, and ensuring the safety of buildings. Thanks to its high load-bearing capacity, flexibility in construction, and exceptional durability, structural steel has become the preferred choice for construction projects ranging from residential to industrial. Let’s explore the remarkable benefits of this material with Viet Son Mechanical in the article below.

1. What is Structural Steel?

Structural steel is a type of metal material produced by hot-rolling or cold-rolling steel billets into various shapes, such as I, H, U, and V. Structural steel offers numerous advantages, including high strength, excellent load-bearing capacity, and ease of processing and installation. Thanks to its robust structure, structural steel is widely applied in residential, industrial, and infrastructure construction.

2. Outstanding Benefits of Structural Steel in Construction

2.1. High Load-Bearing Capacity

- Structural steel possesses exceptional mechanical strength, capable of withstanding heavy loads without deformation.

- Steel beams such as H, I, and U profiles are designed to distribute force evenly, enhancing the structural rigidity of buildings.

2.2. Cost Savings & Material Efficiency

- Compared to concrete, structural steel reduces building weight by up to 30%, lowering foundation and reinforcement costs.

- Saves 10–20% of materials compared to traditional construction methods.

2.3. High Flexibility in Construction

- Easy to assemble, cut, weld, and shape to meet technical requirements.

- Shortens construction time by up to 40% compared to traditional reinforced concrete structures.

2.4. Durability & Long Lifespan

- Structural steel is resistant to corrosion and oxidation when galvanized or powder-coated.

- The average lifespan of structures using structural steel can reach 50–70 years.

2.5. Environmentally Friendly

- Structural steel is 90% recyclable, significantly reducing construction waste.

- Reduces the consumption of natural resources compared to traditional materials.

3. Applications of Structural Steel in Construction

- Factory structures and pre-engineered buildings: Using H and I beams for main frameworks to enhance load-bearing capacity.

- Bridges and high-rise buildings: U and C steel beams strengthen structural stability.

- Industrial machinery structures: L-shaped steel is used for support frames, machine bases, and load-bearing components.

- Shipbuilding industry: H and I beams reinforce ship frames, ensuring structural integrity and stability at sea.

- Energy industry: Structural steel is used in the construction of power transmission towers, wind turbines, and oil rigs.

- Other applications: Structural steel is widely used in many other fields depending on specific requirements.

4. Structural Steel Processing at Viet Son Mechanical

Step 1: Receiving Customer Requirements

- The first step in steel processing is gathering customer requirements, including design drawings, technical specifications, and the number of products needed.

Step 2: Designing

- After receiving customer requirements, engineers use specialized software to design the product. The design software helps determine the dimensions, shapes, and chemical composition of the product.

Step 3: Data Export

- Once the design is complete, engineers export the product data into a file containing drawings, material lists, and machine operation data.

Step 4: Manufacturing

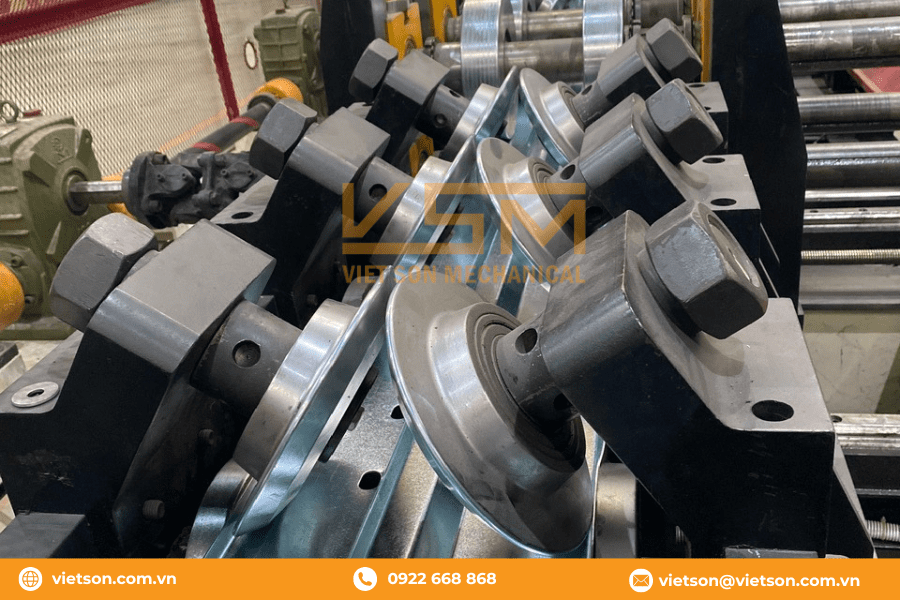

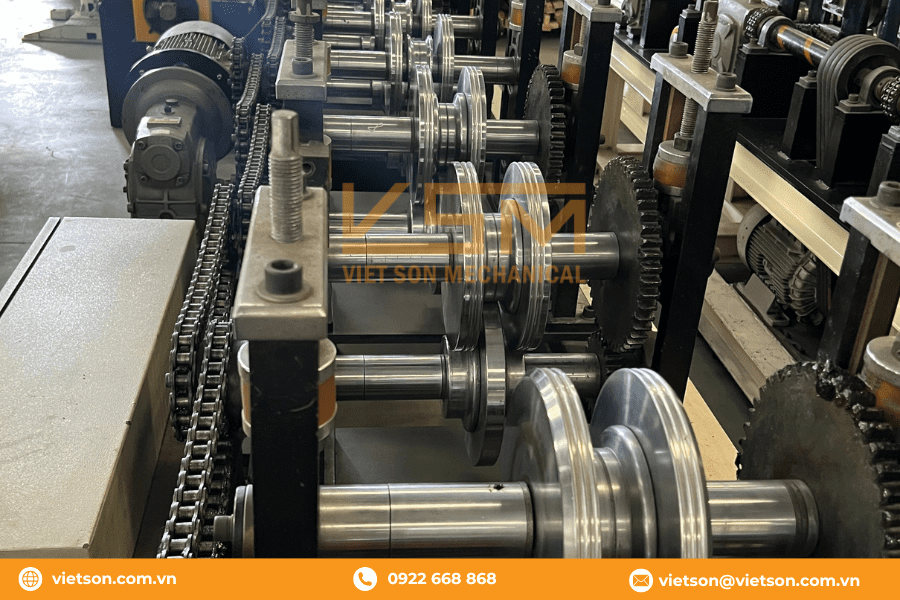

- Based on the exported data, workers begin production. Structural steel is produced using two main methods:

- Hot Rolling: Uses high temperatures to shape steel billets, typically used for large, high-precision products.

- Cold Rolling: Uses pressure to reshape steel billets at room temperature, suitable for smaller products with slightly lower precision.

Step 5: Packaging & Delivery

- After manufacturing, structural steel products are packaged and delivered to customers.

5. Choosing High-Quality Structural Steel at Viet Son Mechanical

5.1. Diverse Structural Steel Products

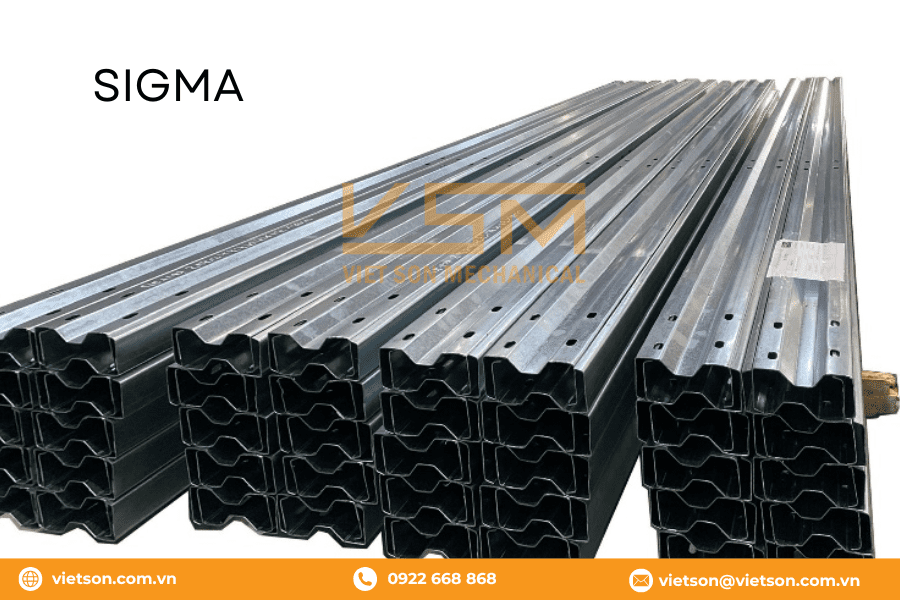

Sigma Purlin

- Sigma purlins feature a balanced center rib design, improving load-bearing capacity and stability by 15% compared to traditional C-purlins.

- Commonly used in warehouse roofs, industrial buildings, and non-crane factory structures.

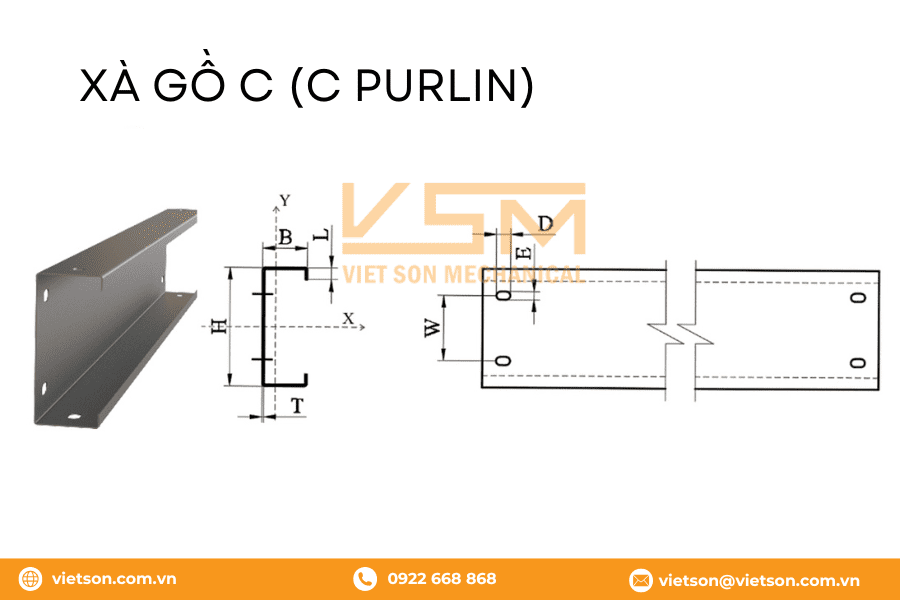

C-Purlin

- Equal-flange design, easy to assemble, lightweight, and strong.

- Used for truss frames, column structures in simple buildings, and projects with spans under 6m.

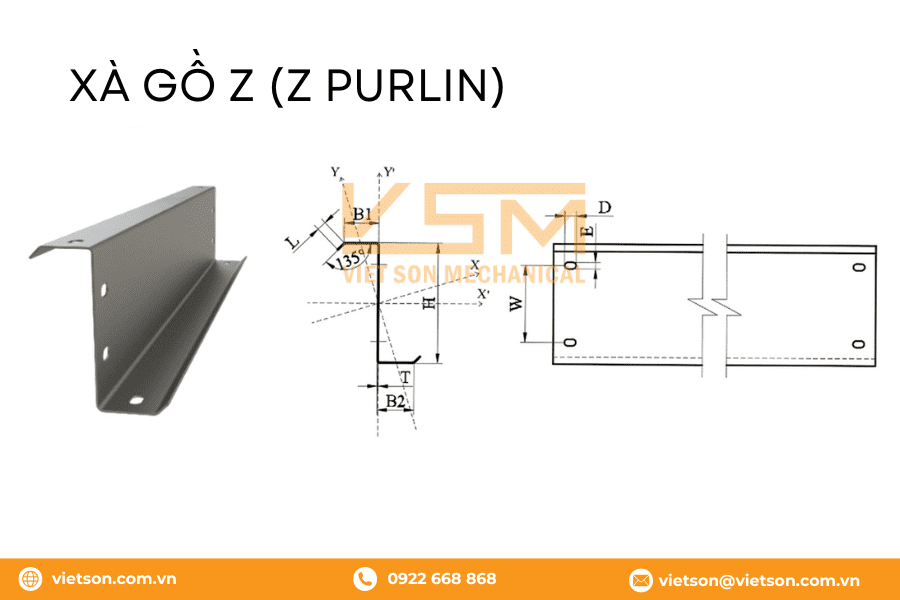

Z-Purlin

- Asymmetrical flange design enhances load-bearing efficiency at critical stress points.

- Ideal for roof and wall purlins, offering compact packaging and easy transportation.

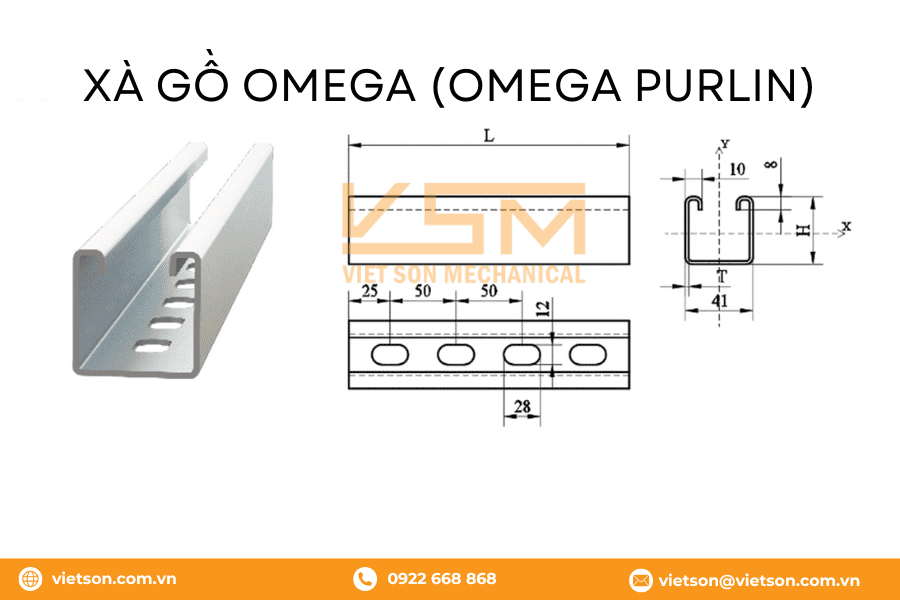

Omega Purlin

- A-shaped cross-section allows stacking for increased structural stability at load-bearing joints.

- Ideal for roof purlin, solar panel mounting systems, and lightweight steel frameworks.

C Truss

- Unequal flange design, enabling easy interlocking for enhanced rigidity.

- Used for roof trusses, partition frames, and interior walls.

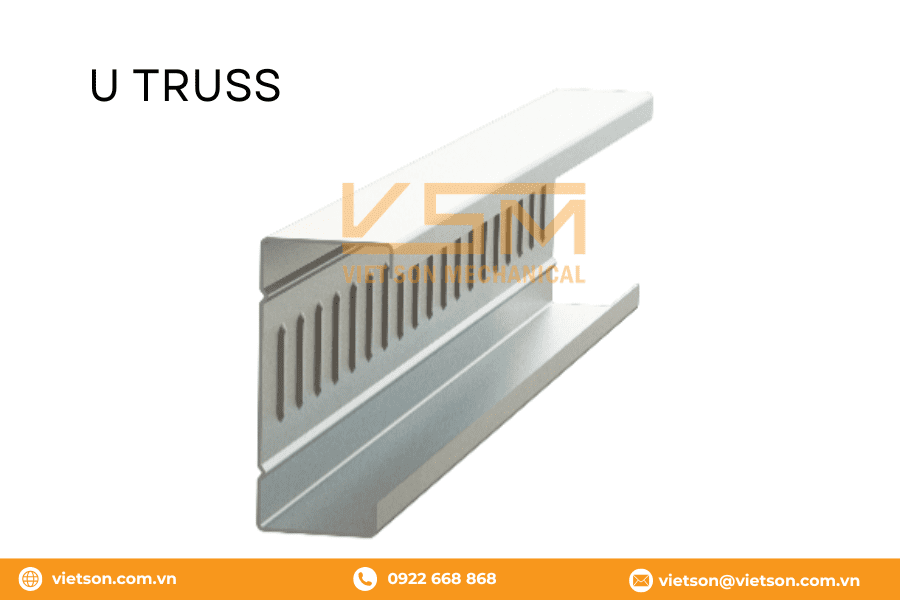

U Truss

- No flange ribs, allowing seamless interlocking with C Truss Beams for additional reinforcement.

- Often paired with C Truss Beams to create strong, lightweight partition walls.

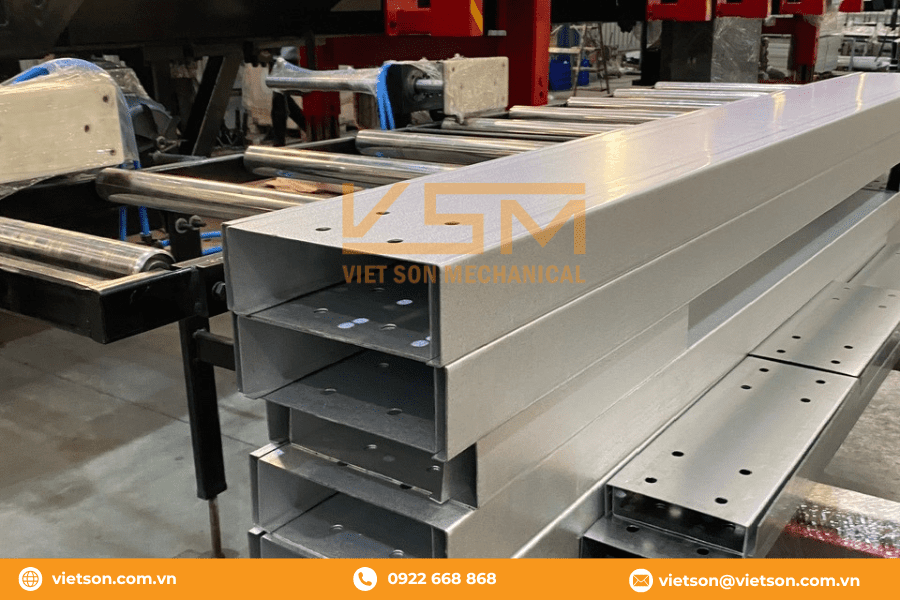

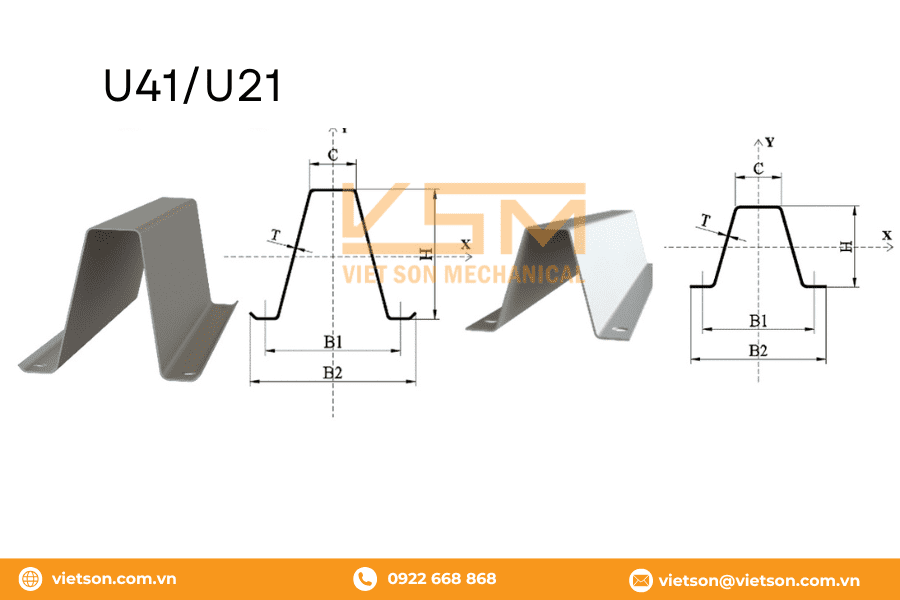

U41/U21

- Pre-punched holes for quick installation, eliminating the need for welding.

- Features flange ribs for enhanced stability and load-bearing capacity.

- Commonly used for electrical support systems and cable tray mounting.

5.2. International-Standard Quality

- Products comply with JIS (Japan), ASTM (USA), and TCVN (Vietnam) standards.

- Strict quality control ensures durability and optimal load-bearing performance.

- Advanced surface treatments enhance corrosion resistance.

5.3. Competitive Pricing & Attractive Offers

- Best prices for bulk orders and long-term contracts.

- High discounts for loyal customers.

- Cost-effective solutions to help clients optimize expenses.

5.4. Professional Consultation & Support

- Technical consultation: Our expert engineers help select the best steel products for your project.

- Nationwide delivery: Fast and reliable shipping ensures timely project completion.

- Warranty policy: Guaranteed according to manufacturer standards.

With years of experience and a solid reputation in the industry, Viet Son Mechanical is proud to supply high-quality structural steel that meets international standards, catering to all customer needs. Contact us today for expert consultation and the best pricing!

Contact Viet Son Mechanical now for the best quotes and expert advice!

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website:https://vietson.com.vn/en

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w