The use of Light Steel Frame solutions is gradually replacing traditional construction methods thanks to their flexibility, fast installation, and cost savings. With over 15 years of experience in mechanical construction, Viet Son Mechanical proudly provides high-quality Light Steel Frame systems that meet all technical and architectural requirements.

In this article, we provide detailed information on Light Steel Frame systems, their advantages, technical specifications, cost-determining factors, and a reference price list from Viet Son Mechanical, helping you choose the most suitable solution for your project.

What is a Light Steel Frame?

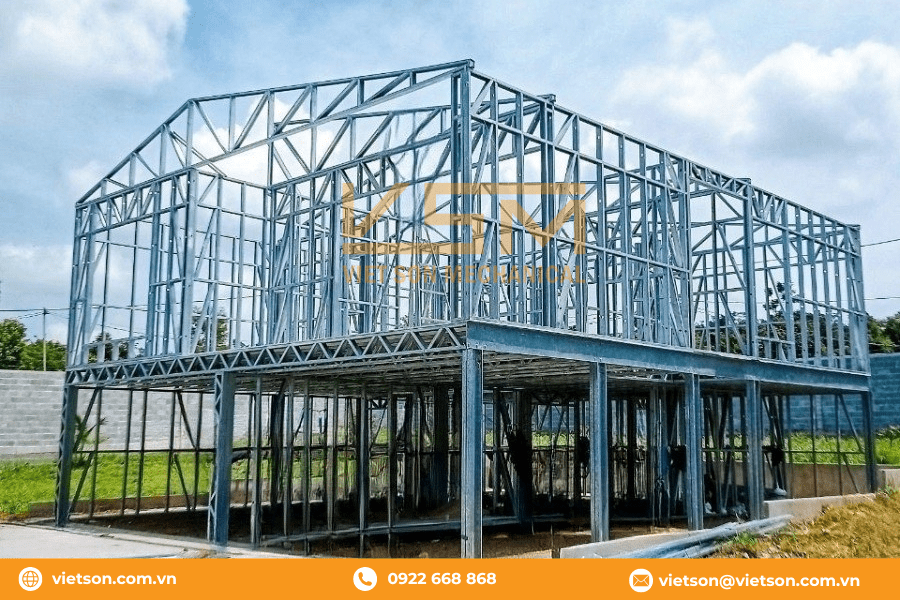

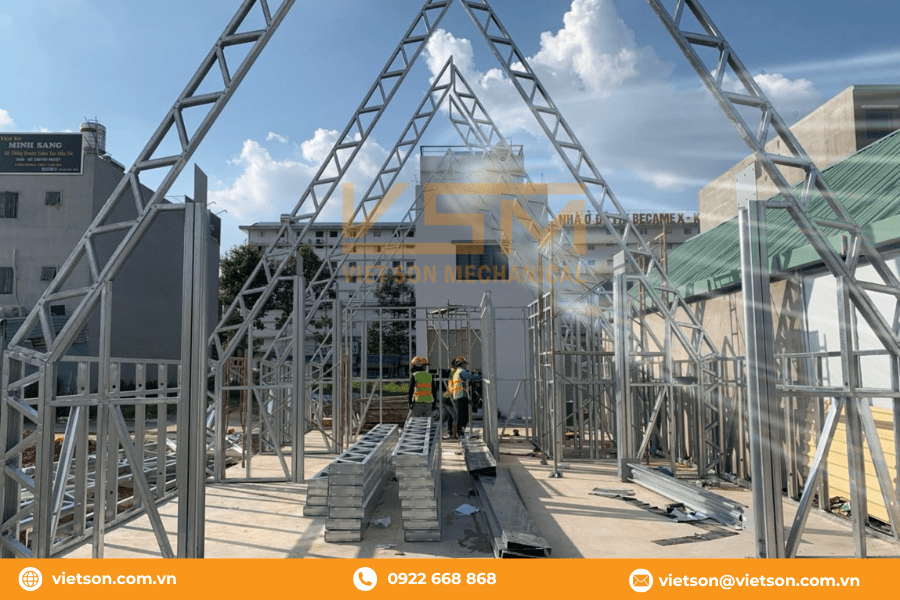

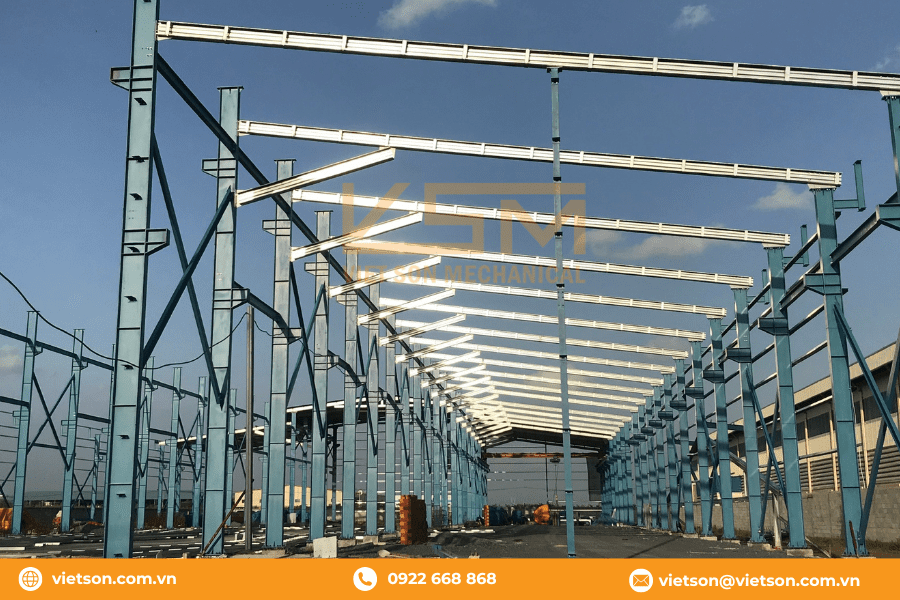

A Light Steel Frame is a structural system made from high-strength steel that is much lighter than conventional structural steel. These frames are pre-fabricated using advanced machinery and quickly assembled onsite. They are commonly used in residential buildings, factories, prefabricated houses, resorts, homestays, warehouses, and farms.

Key Features of Light Steel Frame:

- Uses galvanized or zinc-aluminum alloy-coated steel for anti-rust properties.

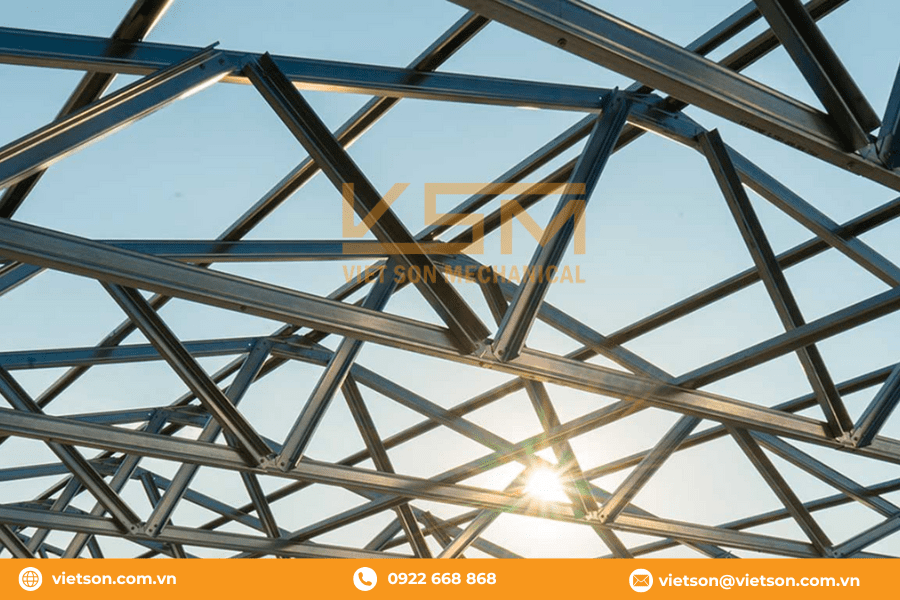

- Assembled via bolts, screws, or welding at connection points.

- Manufactured with automatic roll forming machines (Light Gauge Roll Forming Machine).

- Quick installation and easy expansion for future upgrades.

Technical Specifications of Light Steel Frame by Viet Son Mechanical

When choosing a Light Steel Frame, some standard specifications to consider include:

| Technical Specification | Reference Value |

| Steel thickness | 1.5 – 3.0 mm |

| Section height (C-profile) | 100 – 350 mm |

| Steel length | Based on design |

| Steel strength | G450 – G550 |

| Coating class | Z275 – AZ150 (aluminum-zinc coating) |

| Fabrication tolerance | ±1mm |

Depending on the scale and design of your project, Viet Son Mechanical will customize the frame system to optimize both cost and load-bearing capacity.

Advantages of Light Steel Frame

The use of Light Steel Frame in construction is becoming a key trend due to numerous benefits over traditional methods. Below are the main advantages for investors, contractors, and end users:

1. Lightweight – Quick Installation

Light Steel Frames are made from coated steel with moderate thickness and significantly lighter weight than traditional structural steel or reinforced concrete. This results in:

- Reduced pressure on the foundation, lowering foundation costs.

- Faster transportation, assembly, and completion.

- Minimized use of heavy lifting equipment, saving labor and machinery costs.

2. Rust-Resistant – Long Lifespan

A critical factor in the durability of Light Steel Frames is the protective coating. The steel used is typically zinc-coated or zinc-aluminum alloy-coated (Zincalume), offering:

- Resistance to chemical corrosion in high-humidity or acid rain environments.

- Protection from oxidation due to air exposure.

- Immunity to termites and mold, unlike timber structures.

With coatings like Z275 – AZ150, the average lifespan of Viet Son Mechanical‘s Light Steel Frame systems can reach 30 – 50 years under normal usage, and even longer with proper maintenance.

3. High Precision and Uniformity

Frames are manufactured on automated lines with SmartFrame systems, offering millimeter-level accuracy:

- Ensures consistency among components for on-site assembly.

- Minimizes manual errors and improves construction quality.

- Reduces on-site adjustments as all components are pre-measured at the factory.

4. Easy Expansion, Upgrades, and Reusability

Unlike fixed concrete structures, Light Steel Frames can be easily disassembled and expanded:

- Enables lengthening, floor addition, or renovations without affecting the main frame.

- Ideal for modular projects, resorts, site offices, and temporary facilities.

- Components can be reused in future projects, minimizing construction waste.

5. Fire Resistance – Safety for Property and Lives

A notable advantage of Light Steel Frame structures over materials like wood or concrete (with flammable components) is their fire resistance:

- Steel is non-combustible and does not emit toxic fumes at high temperatures like composite or foam materials.

- The frame structure does not promote fire spread, providing more time for emergency response.

- When paired with fire-resistant materials such as PU/PIR panels, gypsum boards, or insulation layers, it offers superior fire protection.

This level of safety not only protects lives and property but also reduces insurance costs and boosts investor credibility in project operations.

Factors Affecting the Cost of Light Steel Frame Construction

Construction costs for Light Steel Frame systems vary depending on technical and site-specific conditions. Here are the main factors that influence pricing:

1. Project Scale

Project size plays a crucial role in investment:

- Larger projects usually have lower unit costs (VND/m²) due to mass production and optimized logistics.

- However, total investment is higher due to increased material and labor volume.

Factors like total floor area, number of stories, and design requirements (wind resistance, seismic resistance, etc.) also affect pricing.

Example: A single-story 500m² factory will have a lower unit cost than a 100m² one, but a higher overall budget.

2. Materials Used

Material type has the most impact on cost, including:

- Steel type: Galvanized steel, Zincalume, cold-rolled steel—all vary in cost.

- Thickness: From 1.5mm to 3.0mm, chosen based on load requirements—thicker steel is more expensive.

- Coating: Z275 or AZ150 affects both lifespan and pricing.

- Accessories: Roofing, insulation panels, bolts, drainage, doors, etc. are also cost factors.

3. Construction Time

Timing and deadline requirements influence the cost:

- Peak construction seasons (March to August) incur higher labor and material prices.

- Urgent deadlines or overtime work may require extra shifts or faster production—leading to additional costs.

4. Construction Location

Project location affects:

- Transportation costs from factory to site—remote or offshore locations incur higher logistics fees.

- Local labor costs—urban areas have higher rates than rural regions.

- Site terrain—weak soil, slopes, or lack of infrastructure may require special construction solutions.

That’s why Viet Son Mechanical always conducts detailed site surveys to offer the most cost-effective and suitable solution for each project.

Estimated Cost for Light Steel Frame Construction at Viet Son Mechanical

Viet Son Mechanical provides comprehensive Light Steel Frame services including design, fabrication, and installation. Here’s a reference price list:

| Construction Part | Unit Price | Weight per m² | Price per kg |

| Wall & Roof Frame | 1,500,000 VND/m² | ~30 kg/m² | 50,000 VND/kg |

| Floor Frame | 600,000 VND/m² | ~12 kg/m² | 50,000 VND/kg |

Note: The above prices are for reference only. Please contact Viet Son Mechanical for customized quotations based on your project’s design and specifications.

Viet Son Mechanical – Trusted Light Steel Frame Manufacturer in Vietnam

With years of experience and modern facilities, Viet Son Mechanical is a pioneer in manufacturing and installing Light Steel Frame structures to international standards. Our strengths include:

- CNC fabrication facilities in Ho Chi Minh City.

- Professional engineers and architects with deep structural expertise.

- Automated roll forming lines producing various profiles (C, Z, U, Sigma…).

- ISO 9001:2015-certified quality control system.

We have successfully completed numerous domestic and international projects, especially in prefabricated buildings, factories, resorts, site offices, etc.

Do you have a project needing Light Steel Frame construction?

Contact Viet Son Mechanical now for consultation and a detailed quotation:

- Factory: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Cu Chi, HCMC, Vietnam

- Office: 253 Dien Bien Phu, Vo Thi Sau Ward, District 3, HCMC

- Hotline: (+84) 922 668 868 (Zalo – Viber – WhatsApp)

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson?locale=vi_VN

- YouTube: youtube.com/cokhivietson