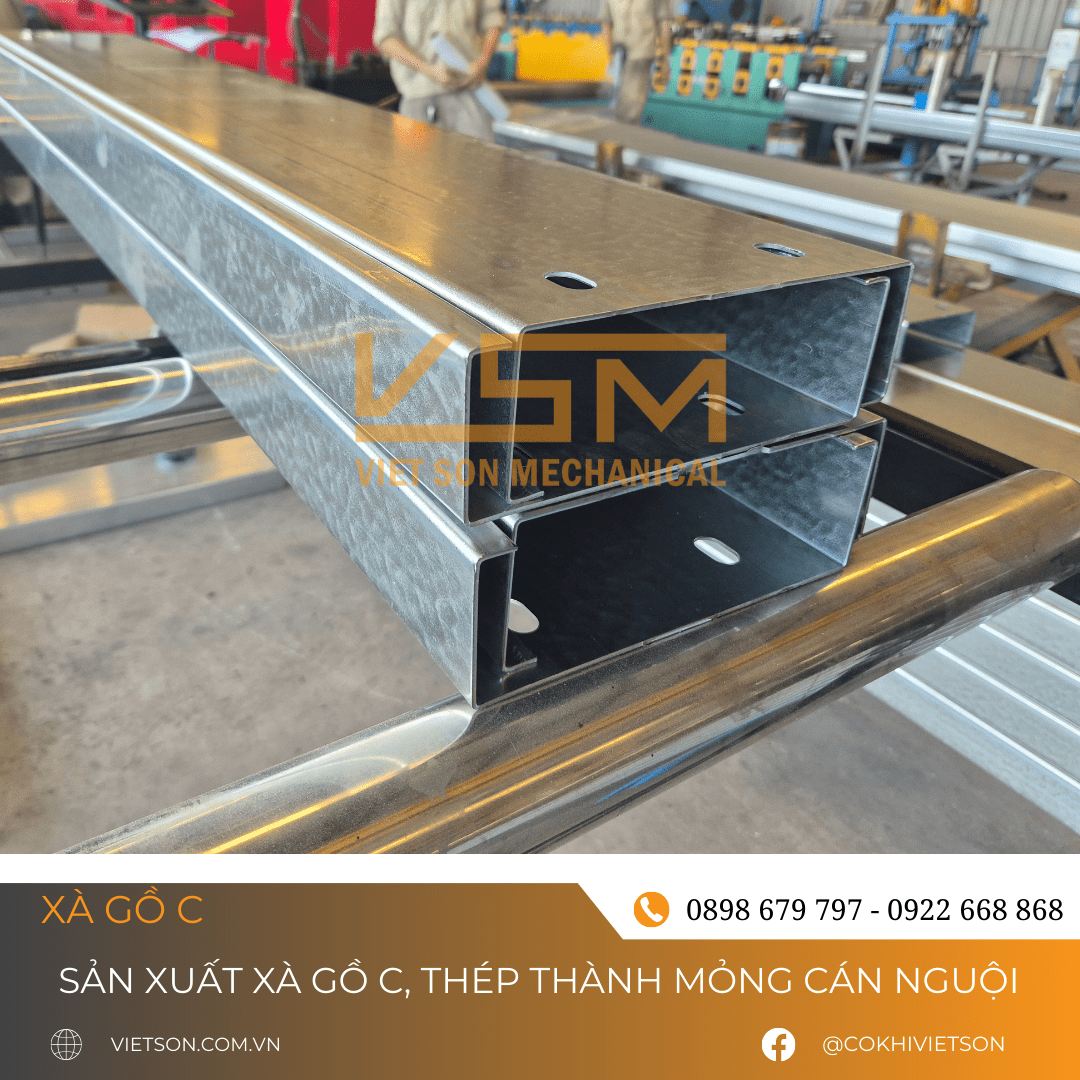

C PURLINS

Deck floor is a steel corrugated iron floor plate that is linked on a steel structural beam system by welding nails. The structure of the deck is a corrugated galvanized sheet. Deck floor is manufactured at the factory with high technical requirements. This type of floor has the effect of replacing floor formwork without a support tree. Combined with bearing forces with reinforced concrete floors, it helps to speed up the construction progress.

In the field of construction and mechanical engineering, the use of C purlins is becoming more and more popular, providing effective solutions for metal structure projects. To meet the increasingly diverse needs of the market, C purlin processing has become a smart choice for construction and metal fabrication companies.

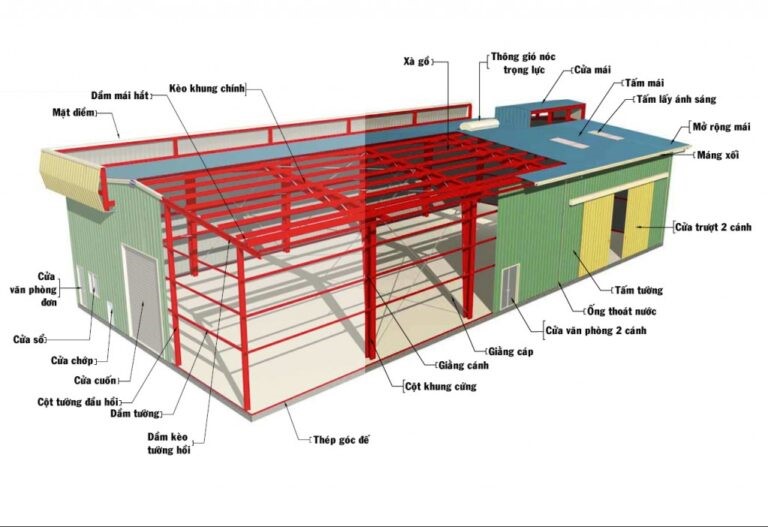

1. C-purlin and its application in construction

C purlin, also known as C-shaped purlin, is an important component in the field of construction and mechanical engineering. Designed with the shape of the letter “C”, C purlin is widely used in many metal structure projects due to its versatility and versatility.

2. C purlin characteristics

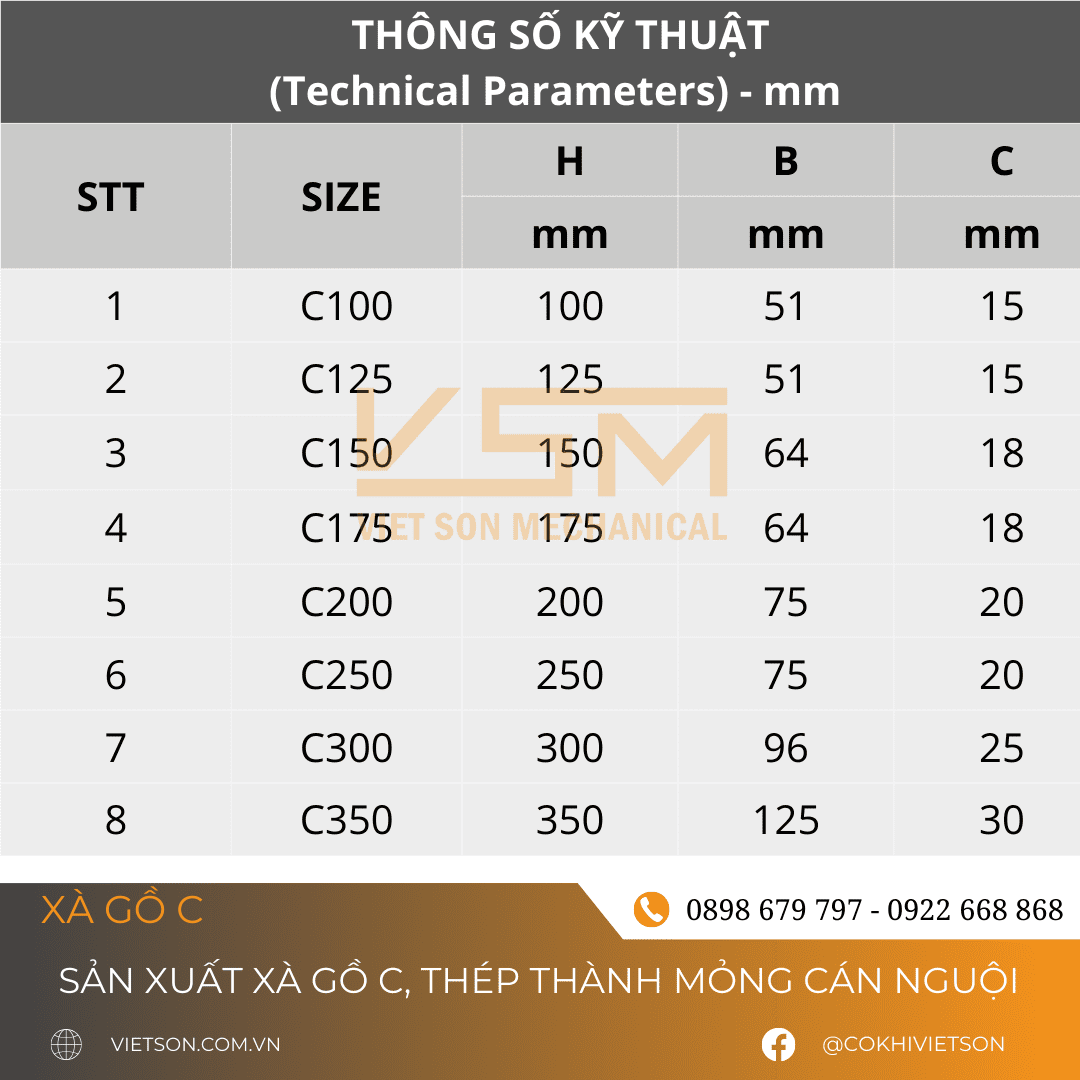

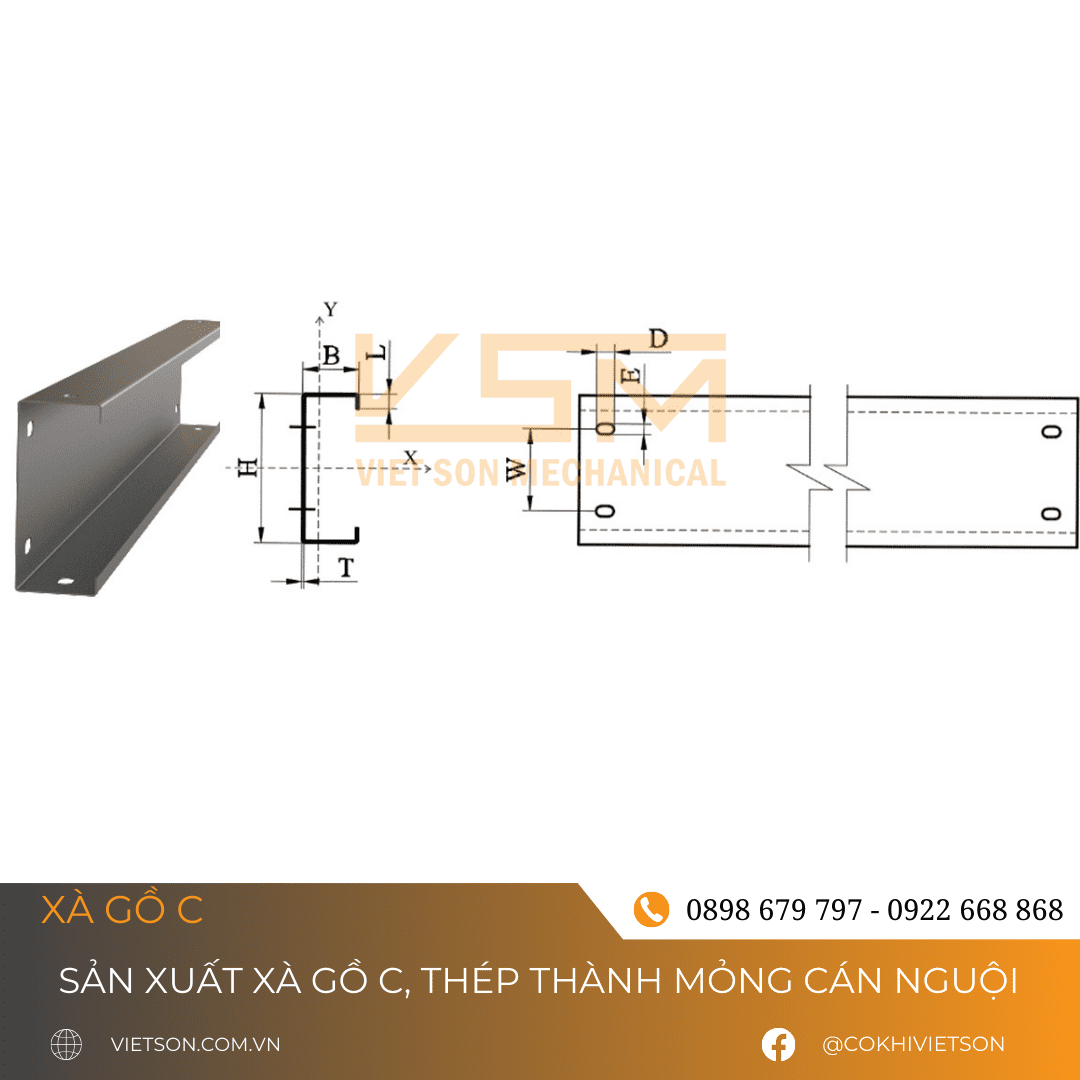

2.1 Variety of shapes and sizes

C-purlins can be produced in a variety of sizes and shapes, from small and light to large and strong. This creates flexibility in design and application.

2.2 High-quality materials

Usually manufactured from high-quality metals such as high-strength steel, C-purlins have good load-bearing capacity and durability, making them suitable for projects that require stability and safety.

2.3 Diverse applications

C-purlins are used in many fields, including bridge and house construction, factory structures, renewable energy projects, and many other applications. This proves its versatility and flexibility.

2.4 Corrosion resistance

If properly fabricated and treated, C-purlins are resistant to corrosion, increasing their ability to maintain shape and durability in harsh environments.

2.5 Advanced Processing Process

Advances in metal processing technology have optimized the C-purlin manufacturing process, from cutting and bending to welding and surface processing, ensuring quality and precision.

3. Applications of purlins

3.1 House Construction

C purlins are used to create load-bearing structures in the construction of high-rise roof structures.

3.2 Workshop and factory structure

C purlins are used in the construction of workshops and factories with flexibility in design.

3.3 Solar Projects

In renewable energy projects, C purlins support the installation of solar panels and other equipment.

4. Advantages of C-Purlin Constructions

4.1 . Durability and load-bearing capacity

C Purlins are made from high-quality metal materials, providing excellent load-bearing capacity and durability. This makes them the preferred choice for projects requiring stability and safety.

4.2 . Flexibility in design

The C purlin fabrication process offers great flexibility in design and shaping, helping to meet specific project requirements. This allows for the creation of products with a variety of shapes and sizes.

4.3. Save time and money

Processing C purlins through modern technology helps optimize the production process, thereby minimizing time and costs compared to free production. On average, the assembly time through pre-processed screw joints of C purlins saves construction and assembly time compared to conventional houses.

4.4. Quality assured

Professional processing units often use high quality control machines and processes, ensuring that C purlins meet technical standards and requirements.

4.5. Adaptation to the environment

With good corrosion resistance and load-bearing capacity, C purlin adapts well to harsh environments, ensuring long-term service life and performance.

5. Why should you process steel profiles at Viet Son Mechanical?

Viet Son Mechanics is a reputable and quality steel processing unit for the following reasons:

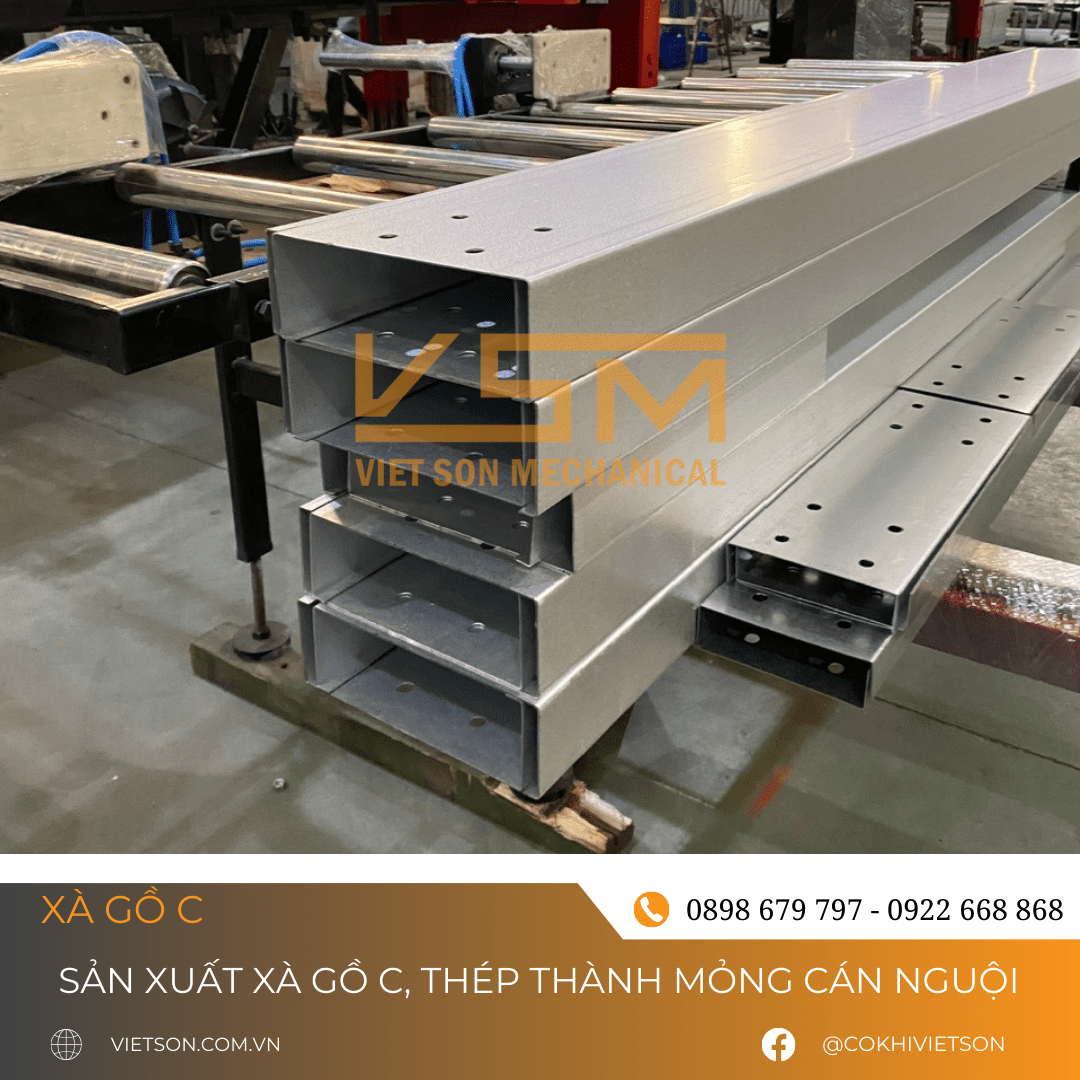

Modern machinery and equipment: Viet Son Mechanical is equipped with modern machinery and equipment to perform steel profile processing efficiently and with quality. This can ensure that the final product meets specific technical requirements and standards.

High Precision: Using advanced machinery and technology, Viet Son Mechanical Engineering is capable of working with high precision, helping the final product to have precise dimensions and characteristics.

Large Volume: Viet Son Mechanical Engineering is capable of large volume, which is especially important if you have a large order or need to mass produce products.

Fully Certified Materials: Viet Son Mechanical Engineering is capable of providing quality certified steel materials, ensuring that your product complies with safety and quality standards.

Guaranteed on schedule: Viet Son Mechanical Engineering can commit to the progress of the project and ensure that your order will be completed on time, which is especially important in construction and industrial manufacturing.

Prestige and quality: Viet Son Mechanical Engineering has a reputation in the metalworking and steel industry, and they are recognized for the quality of their products and services.

As the leading unit in Vietnam in designing, manufacturing, and processing high-quality metal rolling with a variety of models and types according to customer requirements.

Over the years, Viet Son Mechanical Engineering has continuously invested and developed to meet the increasing demand for mechanical services of customers. For the most accurate and detailed quote, please contact us:

► Contact for Machining: 0922 668 868 (Zalo – Viber – WhatsApp)

► Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

► Website: https://vietson.com.vn/

► Email: [email protected]

► Facebook: https://www.facebook.com/cokhivietson

► Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w

Thank you very much for your trust!