Production & construction of smartframe light steel houses

Construction plays a crucial role in the overall development and sustainability of society. Therefore, continuous research and development of construction solutions are being carried out to take the field to new heights – smarter and more convenient.

Smartframe – a pre-engineered thin steel technology, is evaluated as one of the new breakthroughs that will change the future of construction worldwide. SmartFrame technology has advantages such as being lightweight, fast construction, modern, and cost-effective. Viet Son is the pioneering unit in applying this technology in Vietnam.

SMARTFRAME – MODERN TECHNOLOGY SOLUTION

Many high-tech works have been applied from Smartframe technology around the world, but this is still a concept that is not well-known in Vietnam. The technology is applied in creating lightweight steel frame structures for civil and industrial construction using thin steel members, galvanized, high strength, and convenient.

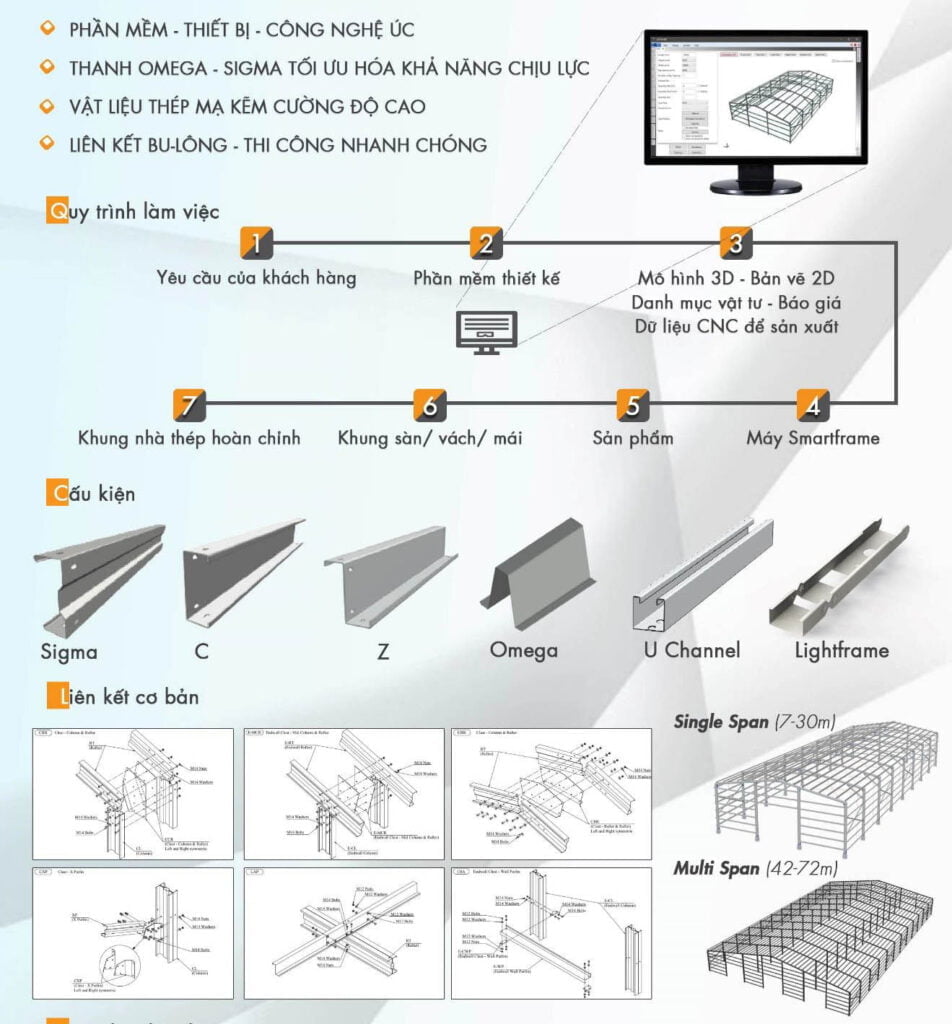

Smartframe connects design software and programming software with the steel structure production line capable of creating the entire structure from the floor to the frame, to the roof with specialized operations. Components are automatically processed on modern CNC machines and synchronized.

Software is responsible for calculating technical parameters such as load capacity, lightweight yet sturdy structure. Moreover, the technology uses high-strength steel to create the most accurate and optimal products. This not only makes the construction process easy and fast but also saves significant project time and costs. It can be seen that Smartframe is a comprehensive solution and aimed at true and sustainable values.

SMARTFRAME – APPLICATIONS AND OUTSTANDING ADVANTAGES

Smartframe is directly applied in construction practice with two product lines: LightShed and LightFrame, respectively applied for industrial and civil lightweight steel houses.

LIGHTFRAME ADVANTAGES

- Integrated SmartFrame machine, automatically controlling the production process.

- Manage order history, customers, and shipping logs, etc.

- Publish detailed drawings, material order forms, installation instructions.

- Automatic computer control system, integrating high-speed inkjet printers and printing codes for each detail.

- Details are accurately processed, assembled simply and quickly.

- The frame structure, walls, floors, and roofs are modularly designed to ensure fast installation.

LIGHTSHED ADVANTAGES

- A flexible industrial steel building system that includes the SmartShed software, Sigma, C, Z purlin machines, Omega purlin machines, pressing machines and CNC plasma cutting machines.

- The SmartShed software is a complete and comprehensive software, from design and control of production machines to installation guidance for your warehouse.

- All machines are synchronized with SmartShed software and integrated with automatic coding printers on products.

- Components are made of high-strength galvanized steel – Shaped – non-welded and non-painted, environmentally friendly and easy to assemble.

- Products are designed with beautiful and modern architecture – Lightweight – Low cost – High economic efficiency.

SMARTFRAME INDUSTRIAL MODEL APPLICATIONS USING LIGHTSHED

Single span

The most economical with 7 – 30m

Multi span – 2

The most economical with 30 – 50m

Multi span – 3

The most economical with 42 – 72m

Multi span – Lean to

The most economical with 42 – 72m

SMARTFRAME CIVILIAN MODEL APPLICATIONS USING LIGHTFRAME

Wall frame structure

Floor Frame

Roof Frame Structure

Basic connections & completed house frames

THE TECHNOLOGY HAS BEEN APPLIED PRACTICALLY IN MANY PLACES AROUND THE WORLD

Structures made of galvanized and shaped steel without paint or welding. Therefore, the assembly process is easy and friendly to the environment. The product meets the criteria that the construction industry constantly strives for, which is durable structure and lightweight. The construction is guaranteed safe from the negative impacts of weather and sustainable over time.

Furthermore, the economic efficiency is also a highly evaluated advantage. According to calculations, SmartFrame contributes to reducing 30% of the time and 60-70% of labor for construction. This directly affects the construction project cost. In the long run, the technology has lower costs with superior structural quality.

SMARTFRAME TECHNOLOGY APPLICATION PROCESS

SmartFrame creates projects according to special requirements, applying Australian technology and not requiring investment in a solid foundation like traditional methods. The special thing is that the process is carried out in a closed and synchronized manner, so that the investor does not have to face any unnecessary inconvenience

SMARTFRAME STEEL HOUSE DESIGN AND CONTRUCTION

The following figures demonstrate the strong capabilities of Viet Son Mechanical:

- Design and construction of over 10,000 factories with different areas.

- 50+ highly specialized domestic and Australian personnel with professional working capacity and attentive customer service.

- 50+ typical projects highly appreciated by professional communities.

- 20 modern machines and equipment such as LightFrame rolling machine, Batten machine, bending machine, plasma cutting machine, along with the most advanced production lines today: C/Z purlin production line, Sigm beam production line.

- Application of technology from Australia to create constructions with thin steel bars according to international standards.

- Some major units that have been our long-term partners such as Duy Tan Plastic, An Viet JSC, and Thanh Phat Mechanical Company.

SmartFrame, with its outstanding advantages and practical applications, has created a new trend in the construction industry. The product achieves a high level of completion in a short amount of time, saves costs, and is suitable for environmental conditions in Asia in general and Vietnam in particular.

Viet Son has applied SmartFrame technology to major construction projects both domestically and internationally, such as house frame construction in Belgium, frame and floor construction in the Philippines, warehouse construction in Ethiopia, warehouse construction in Ben Tre, and the Viet Son factory. This affirms the reputation and quality of projects under the Viet Son Mechanical brand.

For details on manufacturing and construction services for lightweight steel buildings using SmartFrame, please contact our hotline for advice.