Viet Son Mechanical specializes in providing high-quality steel plate machining services, meeting the diverse needs of customers across various industries. With many years of experience and the use of advanced technology, we are committed to delivering steel plate products with high precision, durability, and optimal performance.

I. Introduction to Sheet Steel Machining

What isSheet Steel Machining?

Sheet Steel Machining is the process of transforming steel sheets into specific products or components according to technical requirements. This process often involves methods such as cutting, bending, welding, and surface finishing to create components with accurate dimensions and shapes.

Sheet Steel Machining is a crucial part of the manufacturing industry, helping to produce high-quality products that meet market demands. At Viet Son Mechanical, we provide high-quality Sheet Steel Machining services, using modern machinery and advanced technology.

With the commitment to deliver optimal value to our customers, Viet Son always focuses on quality and precision in every product. Sheet Steel Machining is a critical aspect of the manufacturing industry, and we are proud to be your trusted partner in meeting market needs with high-quality products.

Contact for Sheet Steel Machining:

Phone: 0922 668 868

Website: https://vietson.com.vn/

Email: [email protected]

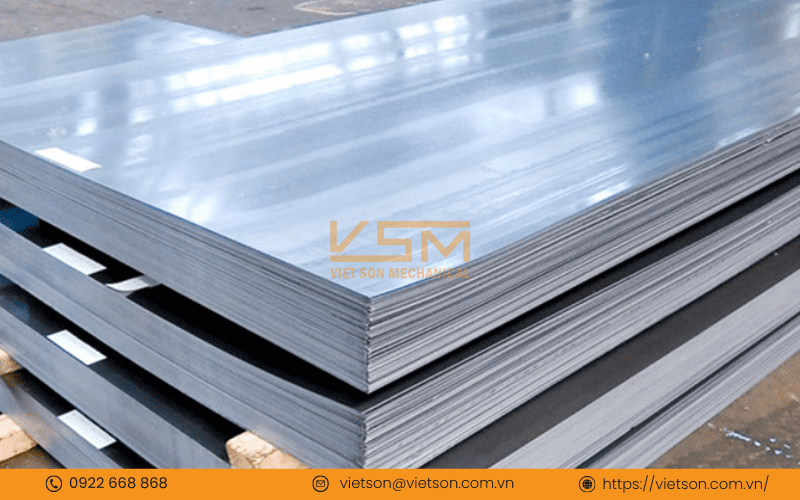

II. Popular Types of Sheet Metal for Machining

Some of the most common types of sheet metal used in machining and manufacturing:

- Carbon Steel Sheet Metal

Characteristics: Carbon steel sheet contains carbon, with carbon content usually ranging from 0.05% to 2.0%. This type of steel is easy to machine and has high strength.

Applications: Commonly used in the production of structural components, machinery, and mechanical parts.

- Alloy Steel Sheet Metal

Characteristics: Alloy steel sheet is produced by combining various alloying elements such as manganese, nickel, chromium, and molybdenum, which enhance the mechanical properties of the steel.

Applications: Often used in applications requiring high strength and durability, such as in machine manufacturing, automotive production, and tool making.

- Stainless Steel Sheet Metal

Characteristics: Stainless steel sheet contains a high chromium content (at least 10.5%), which provides corrosion resistance. This type of steel also maintains a shiny finish.

Applications: Widely used in the food industry, healthcare, and products that require high hygiene standards.

- Mild Steel Sheet Metal

Characteristics: Mild steel sheet typically has a low carbon content, around 0.05% to 0.25%. It is easy to weld and machine.

Applications: Commonly used in manufacturing components that do not require high strength, such as in construction structures, machine enclosures, and consumer products.

- Heat-Resistant Steel Sheet Metal

Characteristics: This type of steel is specially designed to withstand high temperatures without deforming or losing its mechanical properties.

Applications: Often used in the oil and gas industry, boilers, and other high-temperature applications.

- Wear-Resistant Steel Sheet Metal

Characteristics: Wear-resistant steel sheet is produced with high hardness, which helps it resist abrasion and wear during use.

Applications: Commonly used in mining equipment, construction, and other applications requiring high durability.

Each type of sheet metal has its own properties and applications, making it important to choose the right type of steel for machining and manufacturing.

III. Sheet Steel Machining Process at Viet Son Mechanical

The Sheet Steel Machining process involves several steps to transform raw sheet metal into finished products or specific components.

- Material Preparation and Sheet Cutting

Selecting and Inspecting Sheet Metal: Choose the appropriate type of sheet metal based on technical requirements and inspect the quality to ensure there are no defects.

Cutting the Sheet Metal: Use cutting methods such as laser, plasma, or CNC cutting machines according to the design drawing to create the desired shape and size, optimizing material usage.

- Bending and Shaping

Bending the Sheet Metal: Use bending machines to shape the sheet metal as required. This process may include bending, creating angles, or forming other complex shapes.

Size Inspection: Ensure that the dimensions and shapes of the parts after bending meet the technical requirements.

- Welding

Welding Techniques: Use welding methods such as TIG welding, MIG welding, or arc welding to join the parts together.

Weld Inspection: Ensure that the welds meet quality and durability standards, with no defects.

- Surface Machining and Quality Inspection

Surface Treatment and Protection: Perform surface treatments such as grinding, polishing, painting, and applying anti-rust coatings to enhance the aesthetic and durability, while protecting the product from environmental factors.

Quality Inspection: Use measuring tools such as calipers and CMM (Coordinate Measuring Machine) to inspect the dimensions, shapes, and overall quality of the product before delivery.

The Sheet Steel Machining process may vary depending on the specific requirements of each project. With years of experience and advanced technology, Viet Son Mechanical ensures the provision of high-quality Sheet Steel Machining services that meet all stringent technical requirements from customers.

Contact for Sheet Steel Machining:

Phone: 0922 668 868

Website: https://vietson.com.vn/

Email: [email protected]

IV. Sheet Steel Machining Methods at Viet Son Mechanical

Viet Son Mechanical provides a variety of advanced Sheet Steel Machining methods to meet the diverse needs of customers, ranging from heavy industries to high-tech applications.

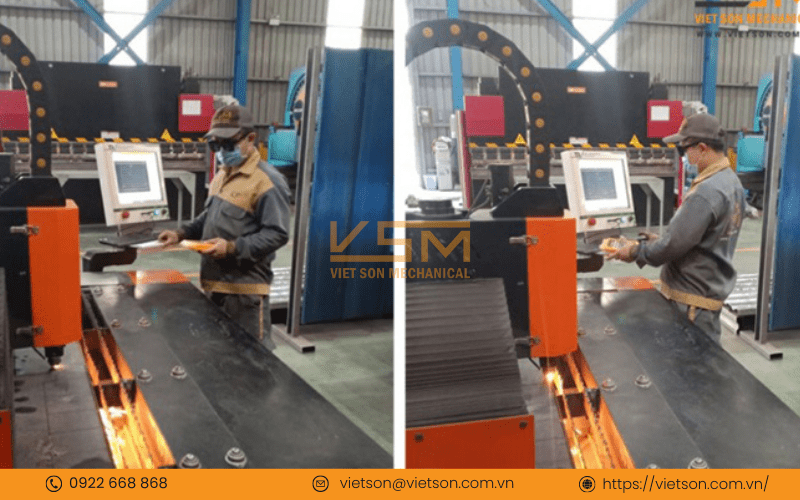

1. CNC Plasma Cutting

Advantages: Can cut thick sheet metal quickly, with high precision and minimal thermal distortion.

Applications: Used for producing thick parts that require complex shapes.

Features: This method uses high-voltage electrical current combined with compressed air to create a plasma jet for cutting steel. Viet Son Mechanical uses CNC plasma cutting machines to ensure precise and smooth cuts.

2. CNC Laser Cutting

Advantages: Extremely high precision, can cut small parts with sharp detail and smooth cut surfaces.

Applications: Suitable for products that require high aesthetic quality, moderate steel thickness, and the machining of complex shapes.

Features: Uses a concentrated laser beam to cut, this method does not cause thermal distortion and creates a smooth surface after cutting.

3. CNC Punching

Advantages: Punches holes or shapes parts with consistent size and high precision.

Applications: Suitable for sheet parts that require many round, square, or special-shaped holes.

Features: Uses a CNC punching machine with high compressive force, capable of rapidly punching multiple holes on the sheet metal surface.

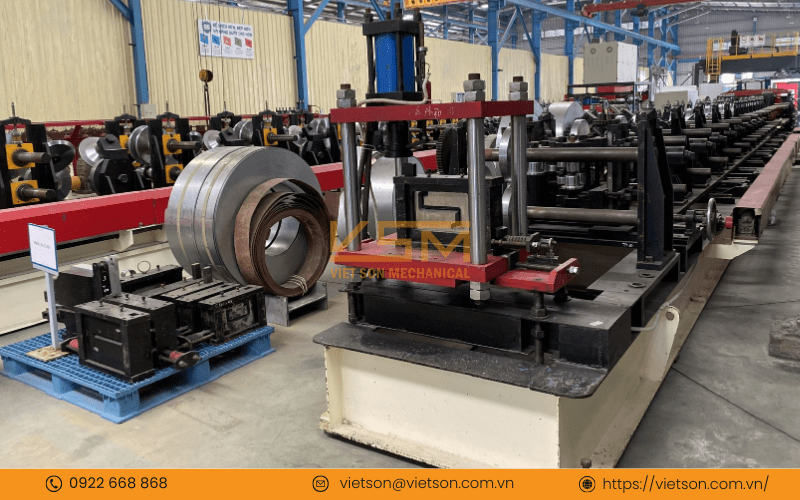

4. Flattening and Shaping

Advantages: Ensures the flatness of sheet metal before other machining steps, helping to reduce errors during production.

Applications: Used before other processes to shape sheet metal to standard specifications.

Features: Uses modern flattening machines to eliminate initial deformations, ensuring flatness before cutting, bending, or punching.

These methods help Viet Son meet the diverse needs of customers, providing high-quality, flexible, and cost-effective Sheet Steel Machining solutions.

V. Advantages of Sheet Steel Machining at Viet Son Mechanical

The advantages of Sheet Steel Machining are becoming increasingly apparent through the growing popularity of this manufacturing method. High precision in production, the ability to create complex shapes, and flexibility in design are key factors that make Sheet Steel Machining the top choice in the manufacturing industry.

High Precision: Sheet Steel Machining uses advanced technologies, allowing the production of highly precise products that meet strict technical requirements.

Flexibility: Sheet Steel Machining methods such as cutting, bending, and welding can be adjusted flexibly according to design requirements, enabling the production of various types of products.

Time and Cost Efficiency: Automating the machining process helps reduce production time and labor costs, while optimizing material usage.

Ability to Create Complex Shapes: Sheet Steel Machining allows the creation of complex shapes that traditional manufacturing methods cannot achieve.

High Durability: Products made from Sheet Steel Machining typically have high durability, meeting the needs of use in harsh environments.

Ease of Surface Machining: Surface processes such as grinding, polishing, and painting can be easily performed, enhancing the aesthetic appeal and corrosion resistance of the product.

Wide Application: Sheet Steel Machining is used in many fields, from construction and machinery manufacturing to automotive production, meeting the diverse needs of the market.

Thanks to these advantages, Sheet Steel Machining has become a popular choice in modern manufacturing industries. If you are looking for high-quality Sheet Steel Machining services, contact Viet Son Mechanical for consultation and support:

- Phone: 0922 668 868

- Website: https://vietson.com.vn/

- Email: [email protected]

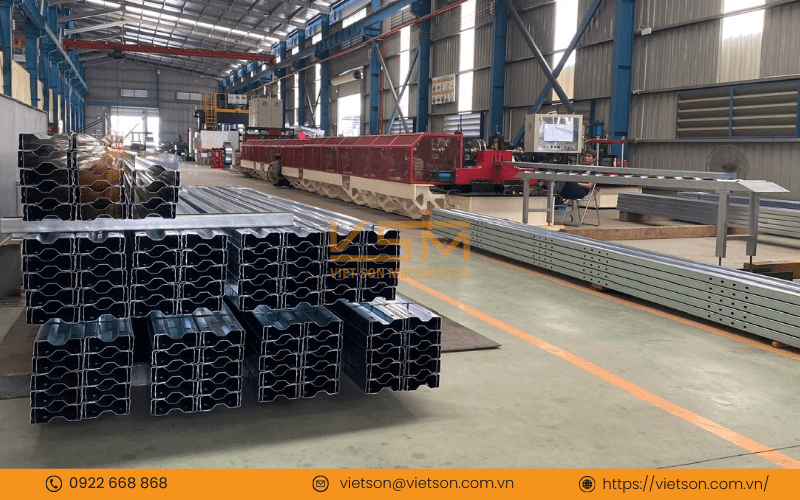

VI. Applications of Sheet Steel Machining at Viet Son Mechanical

Sheet Steel Machining is not only known for its durability and flexibility but is also widely used across various industries.

- Construction

In the construction industry, sheet metal is used to fabricate building frames, bridges, and other large structures. The high strength and load-bearing capacity of sheet metal make it an ideal choice for structures subjected to heavy loads. - Automotive Industry

Sheet metal plays a crucial role in the automotive industry. It is used to produce car bodies, engine covers, and other essential parts, ensuring safety and durability for the vehicles. - Machinery Equipment

In machinery and equipment manufacturing, Sheet Steel Machining is commonly used to produce industrial and agricultural machinery. The ability to form complex shapes meets the high technical demands of the industry. - Manufacturing Industry

Many mechanical parts, such as gears, couplings, and machine frames, are machined from sheet metal. This ensures the quality and performance of mechanical products. - Electrical Industry

Sheet metal is also used to produce electrical cabinets, frames for electrical equipment, and other components. Durability and safety features are critical in this application. - Maritime Industry

Machined sheet metal is applied in shipbuilding, structural frameworks, and maritime equipment. The corrosion resistance of sheet metal is essential in harsh marine environments. - Energy Industry

Sheet Steel Machining is used in the production of energy equipment and energy transport vessels, contributing to the development of the oil, gas, and renewable energy industries.

With its versatility and high durability, Sheet Steel Machining has solidified its importance in many fields. Choosing quality sheet metal ensures that the final product meets technical standards and high performance.

VII. Choosing a Reliable Sheet Steel Machining Provider

Choosing a reliable Sheet Steel Machining provider is a key factor in ensuring the quality of the product and the success of the project. Viet Son Mechanical is proud to continuously improve to bring the best services and products to our clients.

- Experience and Reputation

Long-standing experience in the industry is a determining factor in the reputation of a machining provider. Viet Son Mechanical, with many years of operation in Sheet Steel Machining, has built a solid reputation and earned the trust of customers. - Quality of Service

Viet Son always emphasizes product quality. A strict quality control process ensures that the products meet the highest technical standards. - Technology and Equipment

Viet Son Mechanical is equipped with modern machinery and advanced technology, enabling Sheet Steel Machining with high precision and efficiency. We continuously update new technologies to meet the ever-increasing demands of the market. - Technical Team

The technical team at Viet Son Mechanical not only has high expertise but also the ability to advise and support customers in optimizing designs, thus bringing optimal value to the product. - Customer Service

We are committed to providing the best customer service, always ready to listen to and meet customer needs. Prompt and professional support is our top priority. - Delivery Time

Viet Son Mechanical always ensures the ability to meet delivery deadlines, helping customers maintain project progress while ensuring product quality.

Choosing a reliable Sheet Steel Machining provider not only helps save costs but also ensures that the product meets high-quality standards. Viet Son Mechanical is proud to be one of the most reputable Sheet Steel Machining providers in Vietnam. Contact us for the best advice and support for your project.

Contact for machining: 0922 668 868 (Zalo – Viber – WhatsApp)

Address: Lot C2-7, N7 Road, Tan Phu Trung Industrial Zone, Tan Phu Trung Commune, Cu Chi District, HCMC

Website: https://vietson.com.vn/

Email: [email protected]

Facebook: https://www.facebook.com/cokhivietson

YouTube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w