Solar power systems are becoming a sustainable and cost-effective solution for households, businesses, factories, and industrial zones. One of the core factors that directly impacts the efficiency and lifespan of these systems is the SOLAR FARM FRAME – a mechanical structure designed to hold solar panels in place and optimize sunlight absorption.

With over 15 years of experience in metal fabrication and mechanical engineering, Viet Son Mechanical proudly stands as a leading manufacturer of SOLAR FARM FRAME in Vietnam. We not only provide production solutions but also accompany clients from design consultation to full installation, ensuring optimal efficiency and long-term durability for your solar system.

What is a SOLAR FARM FRAME?

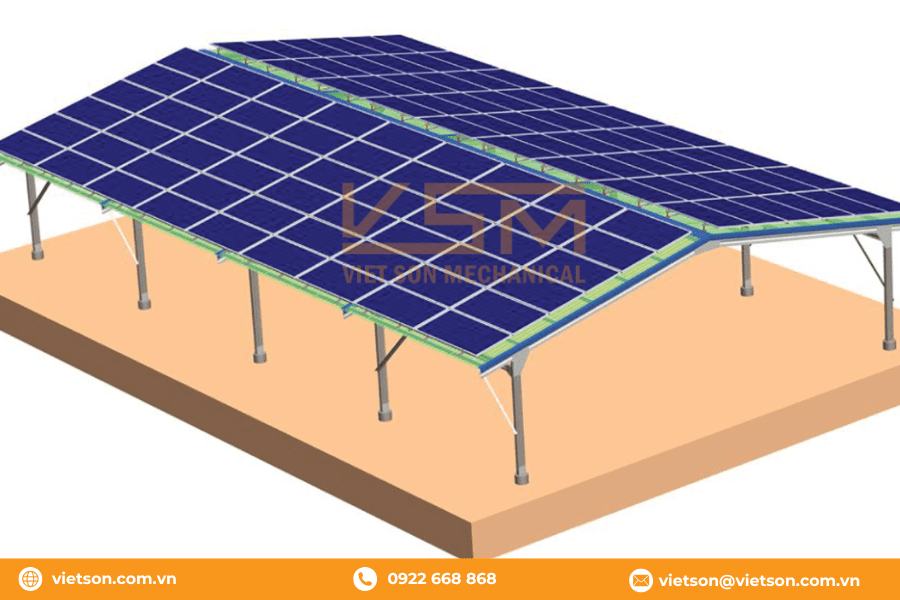

A SOLAR FARM FRAME (also known as a solar mounting structure) is a steel or aluminum framework designed to support and secure solar panels on rooftops or the ground. It plays a crucial role in:

- Determining the tilt angle and orientation of solar panels

- Withstanding wind loads and structural forces

- Ensuring long-term durability in outdoor environments

- Maximizing solar energy yield

Depending on the type of project (solar farm, factory rooftop, residential rooftop…), the SOLAR FARM FRAME will vary in design, materials, and installation methods.

Key Features of a High-Quality SOLAR FARM FRAME

A reliable SOLAR FARM FRAME must meet strict technical standards and requirements for durability, corrosion resistance, and flexible installation. Key characteristics include:

1. Durable Materials

- Aluzinc or Galvalume-coated steel: Rust-resistant, anti-corrosive, lifespan up to 25–30 years

- High-grade aluminum alloy: Lightweight, anti-rust, easy to transport and install

2. Optimized Structural Design

- C, Z, or Sigma profiles enhance rigidity and load-bearing capacity

- Designed to withstand harsh weather in Vietnam (typhoons, strong winds, high humidity)

3. Flexible Installation

- Easy to assemble, disassemble, maintain, and replace

- Compatible with various solar module types

4. High Precision

- Fabricated using advanced CNC machines

- Accurate 2D and 3D design data ensure zero errors during installation

Applications of SOLAR FARM FRAME

SOLAR FARM FRAME has wide applications across many sectors:

- Solar farms: Ground-mounted systems with large-scale capacity, from hundreds of kWp to MWp

- Industrial rooftop solar: Suitable for factories and industrial zones

- Residential solar systems: Installed on houses, villas, and low-rise buildings

- Floating solar systems: Specialized frame designs for lakes, reservoirs, and water bodies

Benefits of Using SOLAR FARM FRAME

Fast Construction – Time-Saving

- Pre-fabricated with high precision, SOLAR FARM FRAME requires only assembly on-site without cutting or welding.

- Installation is 30–50% faster compared to traditional manual methods.

Customizable to Various Terrains

- Viet Son Mechanical designs SOLAR FARM FRAME for different terrains such as hard soil, sandy land, coastal areas, hillsides, and wetlands.

- Flexible solutions help minimize foundation costs and simplify structural adaptation.

Weather-Resistant Durability

- Engineered to withstand wind speeds up to 160 km/h, snow, and heavy rain per international standards.

- Materials like hot-dip galvanized steel and extruded aluminum resist rust even in coastal and high-humidity environments.

Optimized Space Usage

- Smart structural layout maximizes usable area for solar installation.

- Can be customized for single-axis, dual-axis, or floating systems depending on project requirements.

Enhances Asset Value and Brand Image

- A high-quality SOLAR FARM FRAME system delivers a professional appearance and strengthens corporate branding.

- Supports “green enterprise” image and helps achieve LEED, EDGE, or ESG standards.

Ideal for Commercial Solar Investments

- Easy to install, relocate, and scale – suitable for B2B, PPA (Power Purchase Agreement) models.

- Investors can easily adapt according to market demands and project growth.

Viet Son Mechanical – Trusted Manufacturer of SOLAR FARM FRAME

Viet Son Mechanical owns flexible SmartFrame technology, enabling investors to quickly construct solar farms and rooftop SOLAR FARM FRAME systems using Australian-standard technology.

The SmartFrame system includes:

- SmartShed Software

- Sigma/C/Z purlin roll forming machines

- Batten production systems

- Laser CNC cutting and punching machines

SmartShed is a fully integrated software system handling everything from design to production control and on-site assembly instructions.

All machinery is synchronized with SmartShed, including automatic part labeling, on-the-fly dimension adjustment, automatic cutting to any length, and pre-programmed punching.

All components are made from high-strength galvanized steel – roll-formed – with no welding or painting, making it environmentally friendly and easy to install.

Our SOLAR FARM FRAME products are minimalistic in design, durable, lightweight, cost-effective, and economically optimized for both ground-mount and rooftop solar projects.

SOLAR FARM FRAME Production Process at Viet Son Mechanical

1. Project Requirement Intake

We collect basic project details: site area, roof type, module type, capacity, etc.

2. Professional Design Software

We use advanced software including:

- AutoCAD, SolidWorks, Tekla Structures

- PVsyst for energy performance simulation

- SAP2000 for structural strength analysis

3. 3D Modeling and Detailed 2D Drawings

- Full assembly drawings and bill of materials (BOM)

- Accurate CNC data ready for production

- Comprehensive and transparent quotations

4. Manufacturing with SmartShed Line

Modern SmartShed production line ensures:

- Full automation from cutting to punching and packing

- 100% accuracy to design

- Increased productivity, minimized errors

5. Sigma/C/Z Purlin Production

- We manufacture C, Z, or Sigma purlins from hot-dip galvanized steel.

- Precisely roll-formed using high-end machinery.

6. Final Assembly & Quality Inspection

- All SOLAR FARM FRAME products are thoroughly inspected before delivery.

- Packed according to standards, ensuring no deformation or surface damage.

If you are looking for a professional and reliable SOLAR FARM FRAME manufacturer, Viet Son Mechanical is your trusted partner. We are committed to delivering high-quality, cost-effective solutions tailored to your solar energy project.

Let Viet Son Mechanical accompany your clean energy journey!

- Hotline: 0922 668 868 (Zalo – Viber – WhatsApp)

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Zone, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Office: 253 Dien Bien Phu, Vo Thi Sau Ward, District 3, Ho Chi Minh City

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w