Structural steel is one of the most essential materials in the construction and manufacturing industries. With excellent load-bearing capacity, high durability, and a variety of shapes, structural steel is widely used in building frameworks, factories, bridges, and many other applications. The process of rolling and forming structural steel requires advanced technology and precise techniques to ensure high-quality products that optimize costs and enhance construction efficiency.

1. Introduction to Steel Profile Processing Services

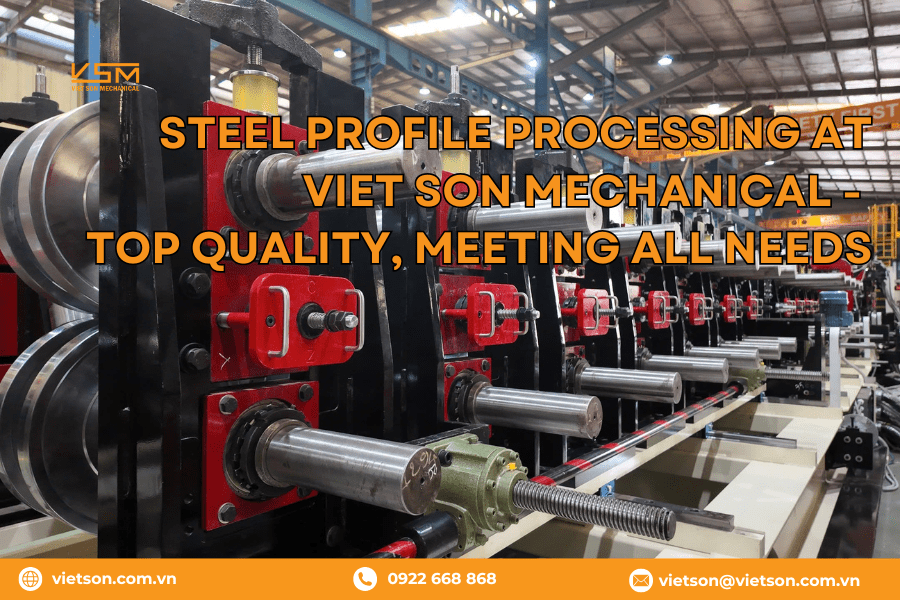

Viet Son Mechanical is proud to be a leading unit in the field of steel profile processing, providing high-quality products that meet the diverse needs of customers in the construction and mechanical engineering industries. With modern technology and a team of experienced technicians, we are committed to delivering high-precision, durable, and cost-effective products.

By applying strict production standards, we ensure that each product when it leaves the factory has high precision, meeting stringent technical requirements. Customers who come to Viet Son not only receive the best products but also benefit from consulting support from a team of experienced experts.

2. Types of Shaped Steel Processed at Viet Son

Viet Son Mechanical specializes in processing shaped steel for various industrial and construction sectors. We provide high-quality rolled steel products, ensuring sustainability and optimal load-bearing capacity.

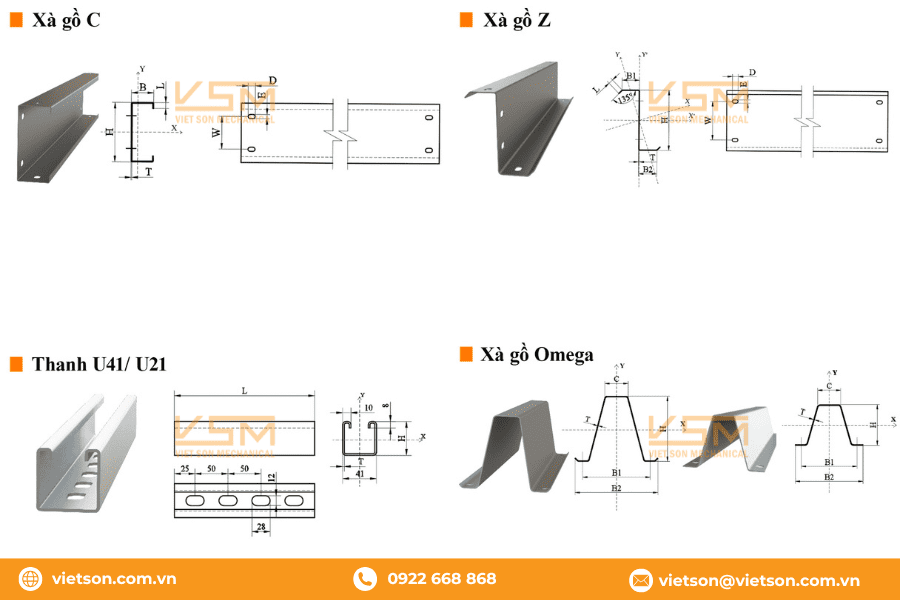

2.1. C, U, Z, Omega Purlin – Widely Used in Construction

- C, U, Z purlin: Commonly used in the structure of factories, pre-engineered steel buildings, canopies, and steel frame systems. With good load-bearing capacity, easy installation, and lightweight, C, U, Z purlin help reduce the load on the structure and optimize construction costs.

- Omega purlin: It is a steel frame reinforcement solution, commonly used in ceiling and partition systems, helping to increase the rigidity and durability of the structure.

2.2. Deck Floor – A Modern Solution for Concrete Floors

Deck flooring is an indispensable material in projects with steel floor structures. This product helps increase load-bearing capacity, shorten construction time, reduce formwork costs, and ensure high durability.

Thanks to the reinforced rib design, the Deck floor can securely bond with concrete, ensuring the structure achieves long-term performance.

>>> Learn more about the types of purlins from Viet Son Mechanical

2.3. Benefits of Using Shaped Steel at Viet Son

- High durability, good corrosion resistance: suitable for various environmental conditions.

- Meeting strict technical standards: ensuring safety and longevity of the structure.

- Production on demand: diverse sizes, suitable for each specific project.

- Competitive pricing: helps optimize costs for contractors and businesses.

3. The Process of Processing Steel Profiles at Viet Son

Step 1: Receive Request

- The customer provides the technical specifications and the required drawings.

- The team of engineers consults and proposes appropriate solutions to ensure the highest product quality.

Step 2: Prepare the Materials

- Choose the type of steel that meets technical requirements and quality standards.

- Check the input materials to ensure there are no defects that could affect the processing.

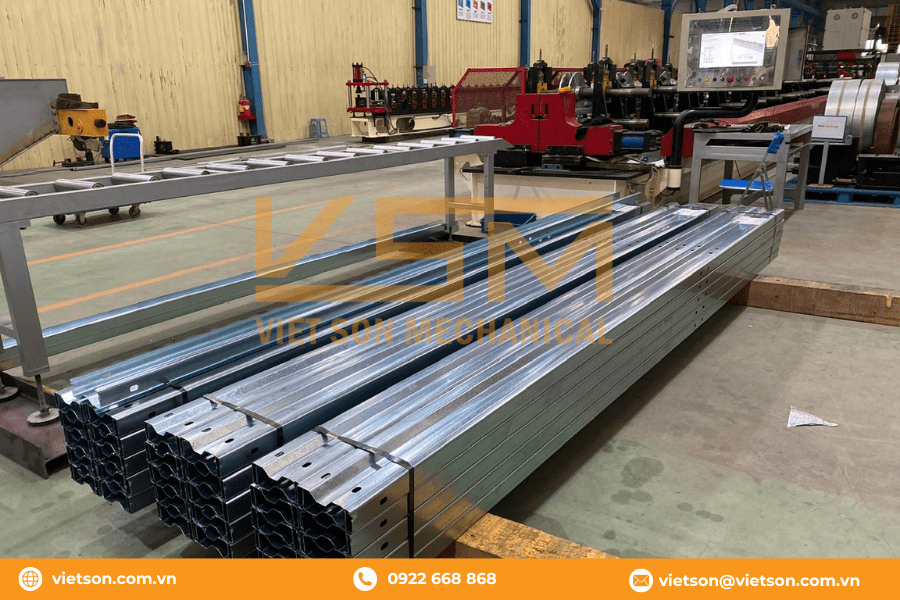

Step 3: Steel Bar Processing

- Cutting process: Steel is cut to the required dimensions using high-tech CNC cutting machines, ensuring absolute precision.

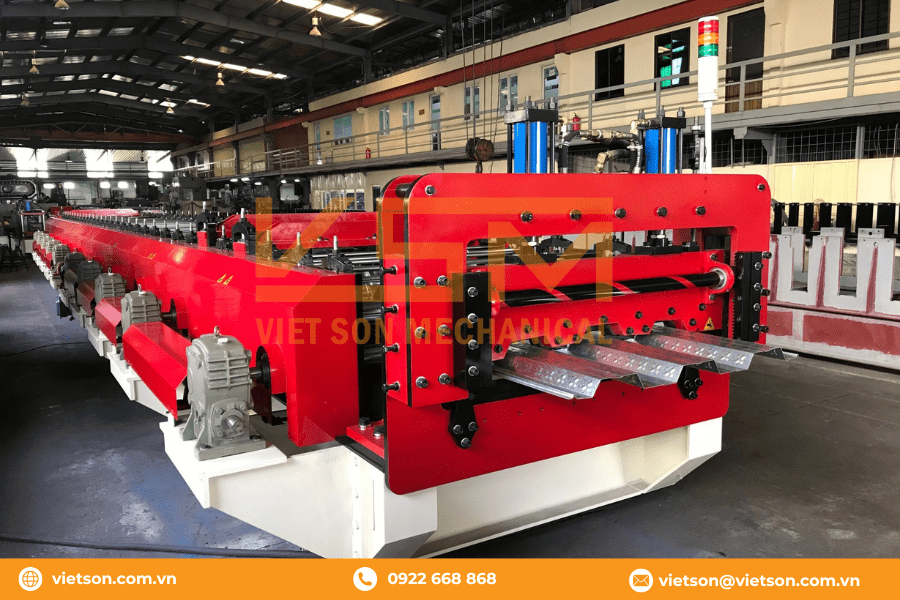

- Rolling process: Using an automatic rolling mill system to shape steel according to standards.

- Shaping and adjusting: The product after rolling is checked for shape, straightness, and technical parameters to ensure it meets the requirements.

Step 4: Quality Check

- Check the thickness, hardness, and load-bearing capacity of the product using specialized measuring equipment.

- Evaluate the surface finish, ensuring there are no technical errors or discrepancies.

- All products must meet standards before being shipped to ensure quality and absolute safety.

Step 5: Finalize and Package

- Proceed with surface treatment to enhance corrosion resistance (galvanizing, powder coating if required).

- Packaging and storing according to standard procedures to ensure the product does not deform during transportation.

Step 6: Timely Delivery

- Fast nationwide delivery, meeting project deadlines.

- Support installation and provide technical consultation if the customer has a need.

4. Why Choose Viet Son Mechanical Engineering?

Quality Meets International Standards

The product is manufactured under strict processes, ensuring durability, high load capacity, and compliance with domestic and international construction standards.

Modern Technology

- We continuously invest in advanced machinery and processing technology to optimize production processes, increase efficiency, and minimize errors.

- Viet Son Mechanical Company owns 50 types of modern machinery and equipment according to ISO 9001:2015 standards.

Competitive Prices

We optimize production costs to offer the most reasonable prices while ensuring product quality, helping customers save the most on expenses.

Professional Customer Service

- The technical consulting team is always ready to assist.

- Clear warranty and maintenance policy.

- Provide flexible machining solutions according to customer requirements.

With the motto “Viet Son Mechanical – Cooperation for Development” we continuously strive to become a reliable partner in the field of mechanical processing. Please contact us for the best consultation and support for your projects!

Contact to book services at Viet Son Mechanical

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website:https://vietson.com.vn/en

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w