I. Introduction to CNC Machining and Traditional Machining

1. What is CNC machining?

Definition of CNC machining technology.

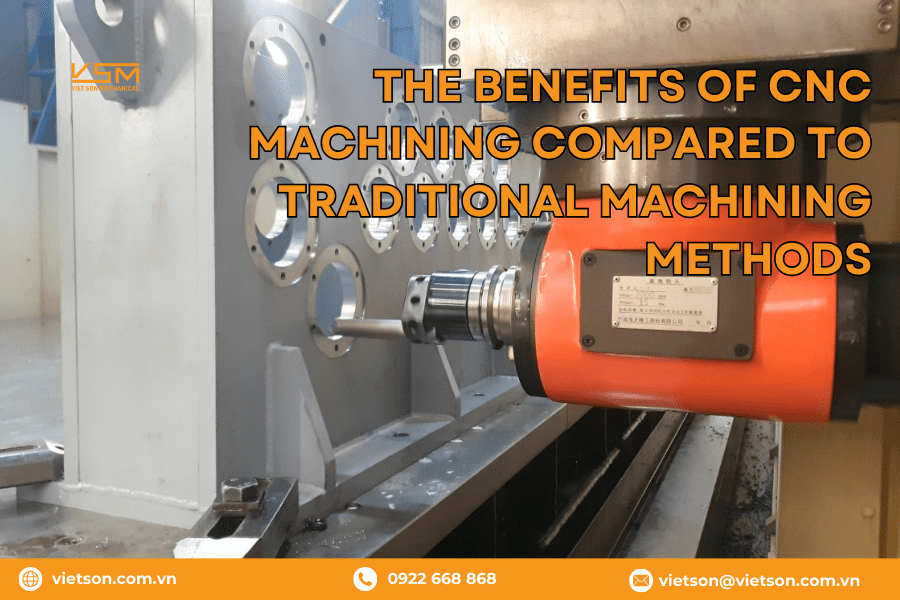

CNC machining (Computer Numerical Control) is a modern mechanical machining method, in which the cutting and shaping of materials are carried out completely automatically thanks to computer-controlled machinery.

The operating principle of CNC machines in mechanical processing.

- Technical drawing design: Use CAD/CAM software to create product models.

- Machining programming: Converting drawings into G-code for the CNC machine to understand and execute.

- Automatic machining: The machine operates according to programmed commands, cutting and shaping materials according to technical specifications.

- Quality control: Measurement, accuracy check before shipment

2. What is traditional processing?

Traditional machining is a method that uses lathes, milling machines, planers, grinders, etc., combined with the manual operations of machinists to shape products.

Popular Traditional Machining Methods

- Turning: Removing material by rotating the workpiece and cutting with a lathe tool.

- Milling: Cutting with a rotating milling cutter to create a flat surface or shape.

- Grinding: Create a shine, increase the precision of the details.

- Drilling: Drill holes according to the required dimensions.

- Planer: Machining flat surfaces, simple curved surfaces.

The Limitations of Traditional Machining

- Dependent on the skill of the mechanic, the accuracy is not high.

- Cannot process complex details.

- Low productivity, time-consuming machine setup, and manual operations.

- High error rate, causing material waste.

3. The trend of CNC technology development in the mechanical engineering industry today.

- Automation: Reducing dependence on manual labor, enhancing production efficiency.

- Smart software application: Integrating AI and IoT to monitor and optimize the machining process.

- The demand for machining complex parts is increasing: Especially in the automotive, aerospace, medical, and electronics industries.

- 5-axis CNC technology: Helps process products with special shapes that traditional CNC machines cannot handle.

II. Comparison of CNC Machining and Traditional Machining

| Criteria | CNC machining | Traditional processing |

| Accuracy and stability | Very high, small error | Depends on the skill of the craftsman |

| Production speed and productivity | Fast, continuous operation | Slower, takes more time |

| The ability to machine complex details | Machining extremely complex details | Limitations with complex designs |

| Level of automation | Completely automatic | Manual, dependent on humans |

| Labor cost | Reduction through automation | High, needs many skilled workers. |

| Waste of materials | Minimize waste, optimize cutting | Wasted a lot due to mistakes. |

III. The Benefits of CNC Machining

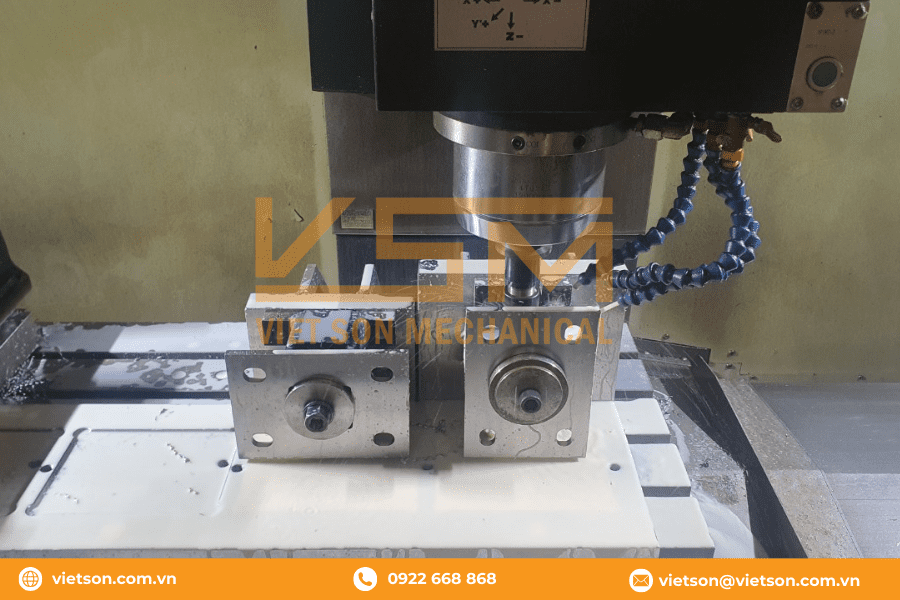

1. High Accuracy, Minimized Errors

- Using numerical control programming helps achieve precision machining down to the micrometer.

- Reduce human error compared to traditional methods.

- Increase the uniformity among the products.

2. Increase Productivity and Save Time

- High-speed machining, continuous without stopping the machine.

- Less manual intervention is needed, reducing machine adjustment time.

- Optimize the production process, accelerate the progress.

3. Ability to Process Various Materials and Complex Details

- Machining on various materials such as steel, aluminum, copper, plastic, composite…

- Easily execute high-difficulty details with small tolerance requirements.

- Well-suited for industries that require high precision such as aerospace, automotive, and medical.

4. Reduce Labor Costs and Technical Errors

- CNC machines operate automatically, reducing dependence on the skills of mechanical workers.

- Limit errors during the processing, reduce the rate of defective products.

- Saving raw materials through more precise cutting.

5. Increase Automation and Efficient Production Management

- Integrating smart control technology helps monitor the production process.

- Support connecting with the production management software system (ERP, MES).

- Easily program, adjust, and monitor CNC machine productivity remotely.

6. Occupational Safety and a Better Working Environment

- Minimize direct contact with cutting tools and hot metal workpieces.

- Reduce noise and vibration compared to traditional machining methods.

- The cooling and dust extraction system helps ensure a safe working environment.

IV. Viet Son Mechanical – Reputable CNC Machining Unit

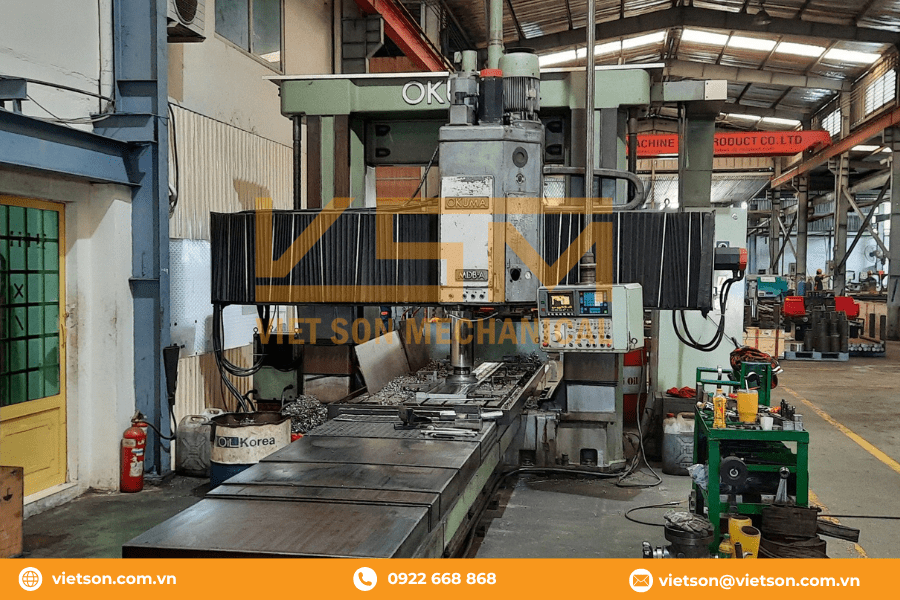

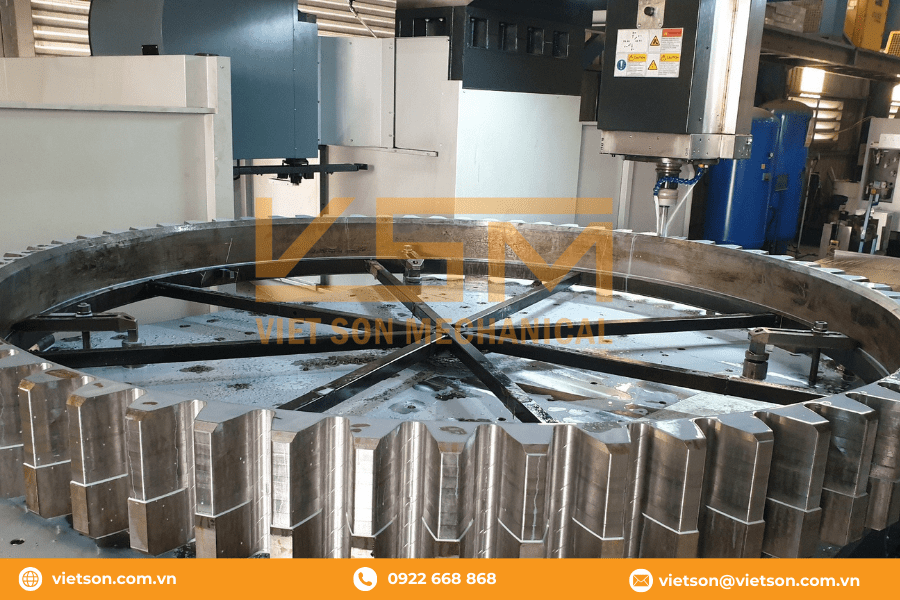

Viet Son Mechanical is one of the leading reputable enterprises in the field of CNC machining of machine parts in Vietnam. With over 10 years of experience in the industry, Viet Son Mechanical has established a solid position thanks to its highly skilled technicians and modern CNC machinery.

The company not only focuses on product quality but also places emphasis on customer satisfaction, providing diverse machining solutions, from milling, turning, to cutting and shaping machine parts.

With continuous efforts to improve and apply advanced technology, Viet Son Mechanical has become a trusted partner of many large and small enterprises across the country, contributing to enhancing production efficiency and meeting market demands.

V. Applications of CNC Machining in the Mechanical Industry

- Automobile manufacturing industry: Machining engine components, chassis, suspension systems…

- Aerospace industry: Manufacturing aircraft components with high precision requirements.

- Healthcare sector: Manufacturing surgical instruments, body implant components.

- Electronics industry: PCB manufacturing, electronic components.

- Mold manufacturing industry: Plastic injection molds, metal stamping molds…

VI. Why Choose Viet Son Mechanical Company for CNC Machining Services?

1. Modern CNC Machining Technology

- Invest in advanced CAM/CAD software technology.

2. Experienced Engineering Team

- Technical expert with many years of experience in the CNC machining field.

- Always update new technologies to enhance machining quality.

3. Product Quality Commitment

- Ensure the product meets high accuracy according to customer requirements.

- Strict quality inspection before delivery.

4. Competitive Prices, Dedicated Support

- Support in consulting, designing, and manufacturing upon request.

- Reasonable prices, optimizing production costs for businesses.

5. Quickly Meet the Schedule

- The automated production system helps ensure delivery schedules.

- The ability to process large quantities in a short time.

Viet Son Mechanical is proud to be one of the leading units in the field of CNC machining of machine parts in Vietnam. With many years of experience in the mechanical industry, we are committed to providing high-quality machine part processing services that meet all the stringent requirements of our customers.

With the motto “Viet Son Mechanical – Cooperate for Development” we continuously strive to become a reliable partner in the field of mechanical processing. Please contact us for the best consultation and support for your projects!

Contact to Order CNC Machining Services at Viet Son Mechanical

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website: https://vietson.com.vn/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w