Modernity in processing shaped rolled steel

In the process of processing shaped rolled steel at Viet Son Mechanical, modernity is clearly demonstrated through the application and combination of the most advanced technologies in the mechanical industry. With investment in modern equipment and flexible working processes, we ensure to bring customers products with optimal precision and quality.

High-end processing machinery: We use top-notch processing machinery, equipped with advanced technology such as CNC laser cutting machines, CNC milling machines, and other precision processing equipment. This helps us handle every detail and shape with great precision.

- C purlin rolling machine

- Z purlin rolling machine

- Omega bar rolling machine

Flexible working process: The team of technicians and artisans at Viet Son Mechanical are highly trained and have the ability to work flexibly in an industrial environment that requires agility and creativity. Workflow is optimized to ensure efficiency and flexibility in machining.

Diverse metal materials: Modernity is also reflected in the ability to process many different types of metals such as stainless steel, iron, steel, and aluminum, providing flexibility in choosing materials depending on requirements. specific to each project.

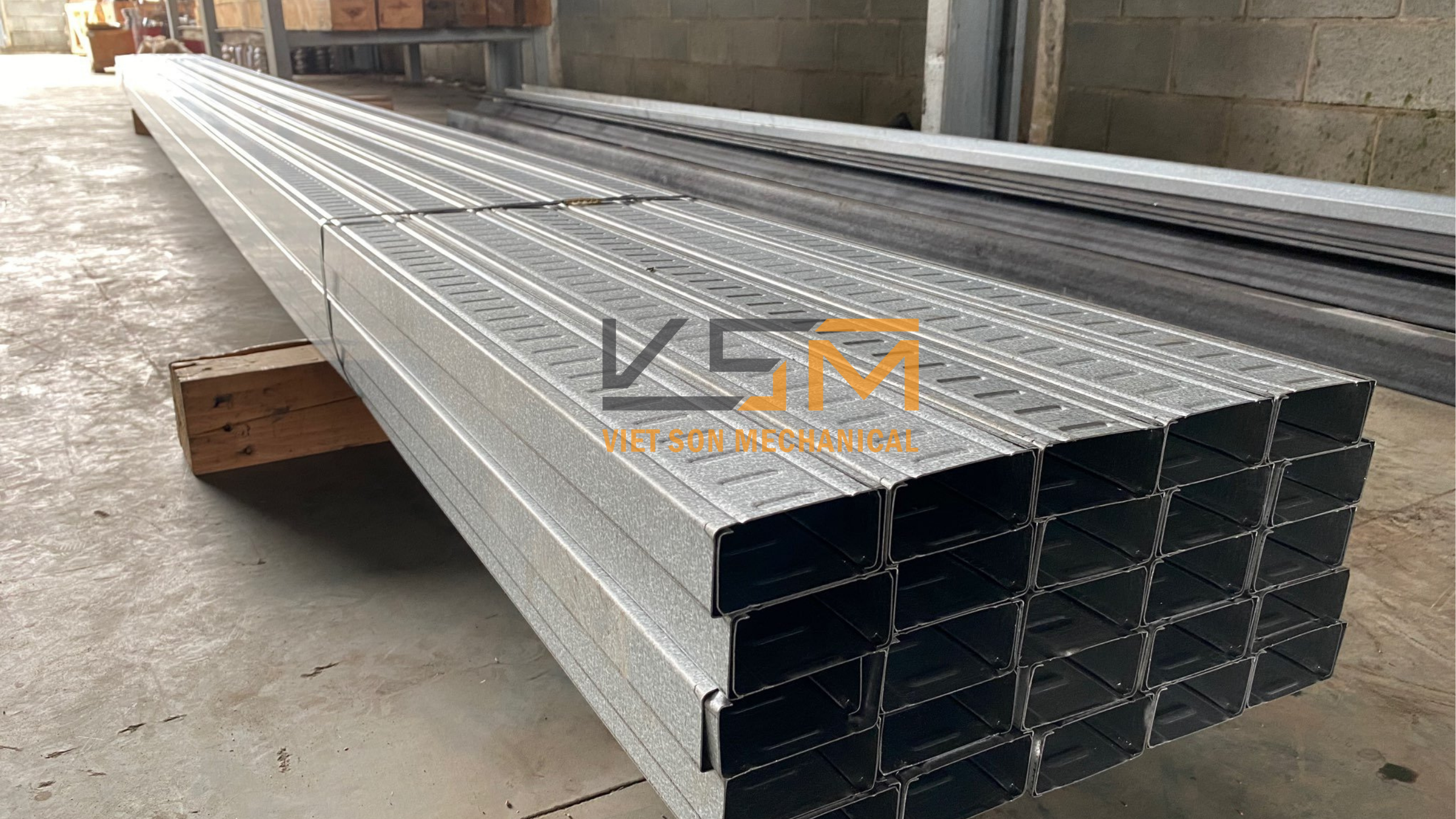

- Rolled steel products

- Rolled steel products

Strict quality control: The quality control process is strictly carried out at every step, from design to production. This ensures that every product processed meets the highest quality standards.

With the perfect combination of modern equipment, professional staff and efficient working processes, we are committed to providing customers with the most innovative and classy rolled steel processing solutions. .

Necessary notes when choosing steel in constructio

Iron and steel play an important and indispensable role in all construction projects, regardless of whether they are large or small. On the market today, there are many types of iron and steel such as rolled steel, rebar, shaped steel, steel plates, box steel, steel pipes… Each of these types of iron and steel is applied to projects with different purposes and properties. different. Therefore, there are a few notes you need to pay attention to before buying construction steel as follows:

To carry out a strong and effective construction project, determining the quantity and calculating the cost of raw materials, especially iron and steel, is an important first step. This helps avoid waste and ensures resources are used appropriately.

Next, surveying prices and choosing an iron and steel brand is an important decision. The quality of iron and steel affects the durability and safety of the project, so carefully reviewing the documents and origin of the product is extremely important.

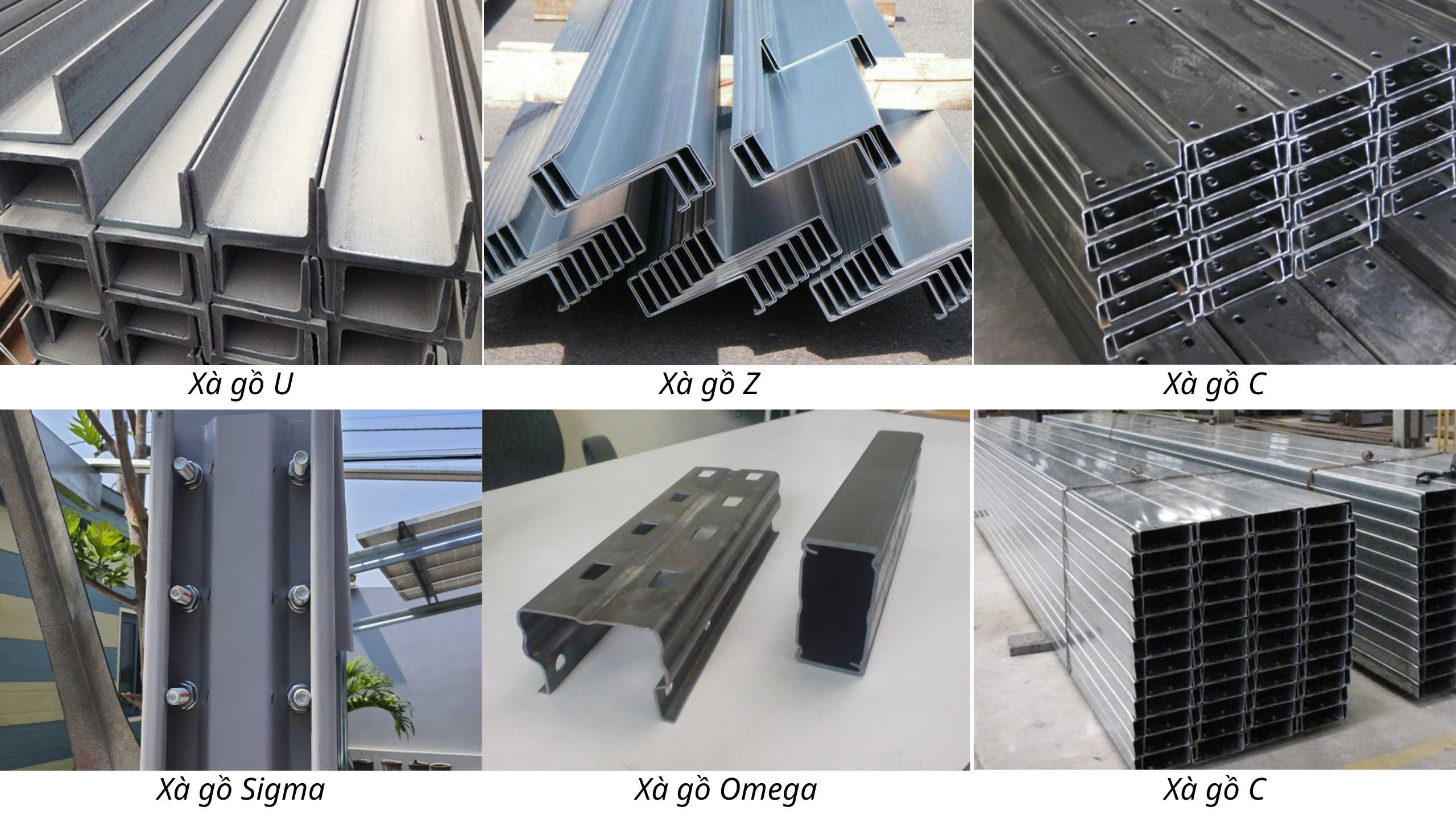

Purlin C

Advantage

High bearing capacity: C purlins have good bearing capacity and can withstand large loads.

High durability: C purlins are highly durable and can be used for a long time.

Good rust resistance: C purlins are made from galvanized steel or aluminum with good rust resistance, suitable for projects in harsh environments.

Easy to construct: C purlins have a simple structure and are easy to construct and install.

Reasonable price: C purlin has a reasonable price, suitable for many users.

Application of C purlins

Used as roof beams, floor beams, purlins in factories, warehouses, high-rise buildings, etc.

Also used as frames for partition systems, ceilings,

Reference link: https://vietson.com.vn/san-pham/xa-go-c/

Z purlin

Advantage

High bearing capacity: Z purlins have good bearing capacity and can withstand large loads.

High durability: Z purlins are highly durable and can be used for a long time.

Good rust resistance: Z purlins are made from galvanized steel or aluminum with good rust resistance, suitable for projects in harsh environments.

Easy to construct: Z purlin has a simple structure, easy to construct and install.

Reasonable price: Z purlin has a reasonable price, suitable for many users.

Z purlin application

Z purlins are used as roof beams, floor beams, and purlins in factories, warehouses, high-rise buildings, etc.

Z purlins are also used as frames for partition systems, ceilings, etc.

Reference link: https://vietson.com.vn/san-pham/xa-go-z/

U purlin

Advantage

High bearing capacity: U purlins have good bearing capacity and can withstand large loads.

High durability: U purlins are highly durable and can be used for a long time.

Good rust resistance: U purlins are made from galvanized steel or aluminum with good rust resistance, suitable for projects in harsh environments.

Easy to construct: U purlins have a simple structure and are easy to construct and install.

Reasonable price: U purlins have a reasonable price, suitable for many users.

U purlin application

U purlins are used as roof beams, floor beams, and purlins in factories, warehouses, high-rise buildings, etc.

U purlins are also used as frames for partition systems, ceilings, etc.

Reference link: https://vietson.com.vn/san-pham/xa-go-u/

Unit that processes rolled steel with the best price in the city. HCM

In a diverse market, choosing a reputable supplier is a decisive factor. Viet Son Mechanical is the unit that receives requests for processing rolled steel at the best price in Ho Chi Minh City, with a leading reputation in the field of iron and steel supply, not only committed to quality but also to price. competitive and dedicated service. Viet Son’s partners are always satisfied with the diversity of designs, reputable quality and import value from leading factories in the world.

If you need to process rolled steel, please contact Viet Son for a detailed quote!

► Contact for processing: 0922 668 868 (Zalo – Viber – WhatsApp)

► Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, City. HCM

► Website: https://vietson.com.vn/

► Email: [email protected]

► Facebook: Viet Son Mechanical

► Youtube: Viet Son Mechanical