Is your business struggling with costly, labor-intensive, low-efficiency, and unsafe cargo loading into containers? Are frequent errors in the loading process costing you millions each month in damaged goods and delayed deliveries?

An optimal solution is here – the Container Loading System is your ultimate assistant in solving productivity, cost, and accuracy challenges in your import-export operations.

What is a Container Loading System?

A Container Loading System is a specialized device designed to assist in automatically or semi-automatically loading cargo into shipping containers. This equipment can handle heavy items, palletized goods, loose cargo, and bulky materials with high precision and safety.

It is commonly used in manufacturing plants, warehouses, logistics centers, and is especially useful in industries such as steel, construction materials, food, electronics, and heavy machinery.

Advantages of Using a Container Loading System

Investing in a Container Loading System brings a range of practical benefits:

- Labor cost savings: Reduces manual labor and minimizes workplace accidents.

- Increased loading efficiency: Speeds up the container loading process significantly compared to traditional methods.

- High accuracy and safety: Automated operation ensures proper placement of goods and reduces the risk of damage.

- Easy integration into production lines: Compatible with conveyors, palletizers, and robotic arms.

- Optimized container space usage: Maximizes container capacity, reducing the number of containers needed.

Key Features of the Container Loading System

Depending on your business needs, the Container Loading System manufactured by Viet Son Mechanical can be customized with outstanding features such as:

- Used to pack all kinds of goods into containers: sandwich panel, shape steel, pipe steel, wood, stacked goods,..

- Both legs can be adjusted for height and side variations to align the loading plate with the container.

- System is controlled by PLC program. The working process is monitored, easily controlled via touch screen.

- System can be transferred by wheels to other loading/unloading points.

- Packing for containers up to 40ft.

- Laser light and rollers are included for easily aligning and positioning goods.

- Packing time is shorter in comparison to traditional solutions (10 minutes/container 40ft).

- Require less labor.

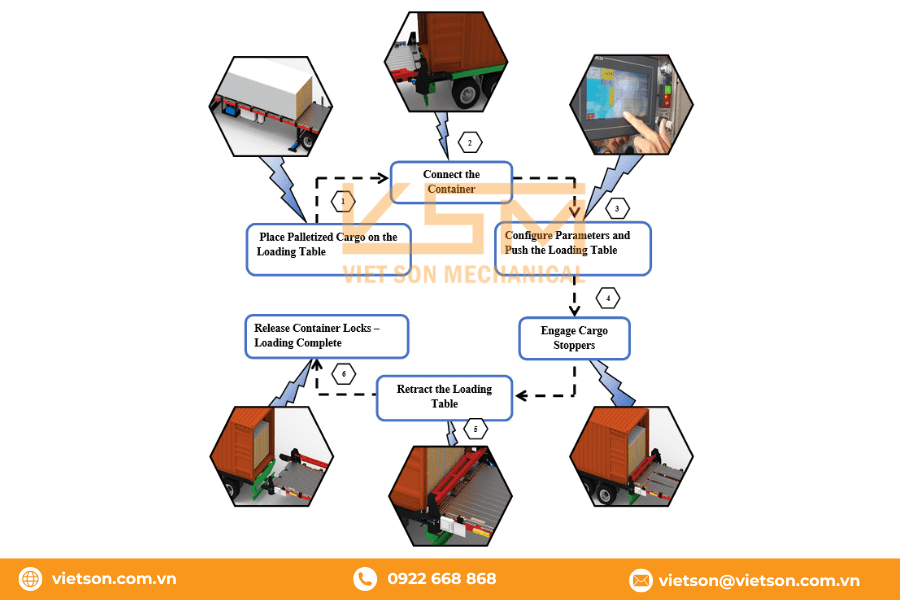

How the Container Loading System Works

The operation process of the Container Loading System by Viet Son Mechanical is intelligent, easy to operate, and ensures absolute safety. It follows six basic steps:

Step 1: Place Palletized Cargo on the Loading Table

After packaging, the cargo is placed onto the mobile loading table using a forklift or conveyor. Pallets are aligned to ensure accurate loading into the container.

Step 2: Connect the Container

The container is positioned and securely connected to the system via locking clamps, ensuring alignment and preventing shifting during operation.

Step 3: Configure Parameters and Push the Loading Table

Operators set necessary parameters on the control panel (pallet count, push distance, speed). The machine then automatically pushes the loading table along with the cargo into the container.

Step 4: Engage Cargo Stoppers

Once the table reaches the designated position, automatic stoppers close to fix the cargo in place and prevent shifting during transportation.

Step 5: Retract the Loading Table

The machine retracts the loading table, leaving all the palletized cargo neatly inside the container.

Step 6: Release Container Locks – Loading Complete

Finally, the container locks are disengaged. The container is detached from the system, ready for shipping. The process is safe, fast, and highly efficient.

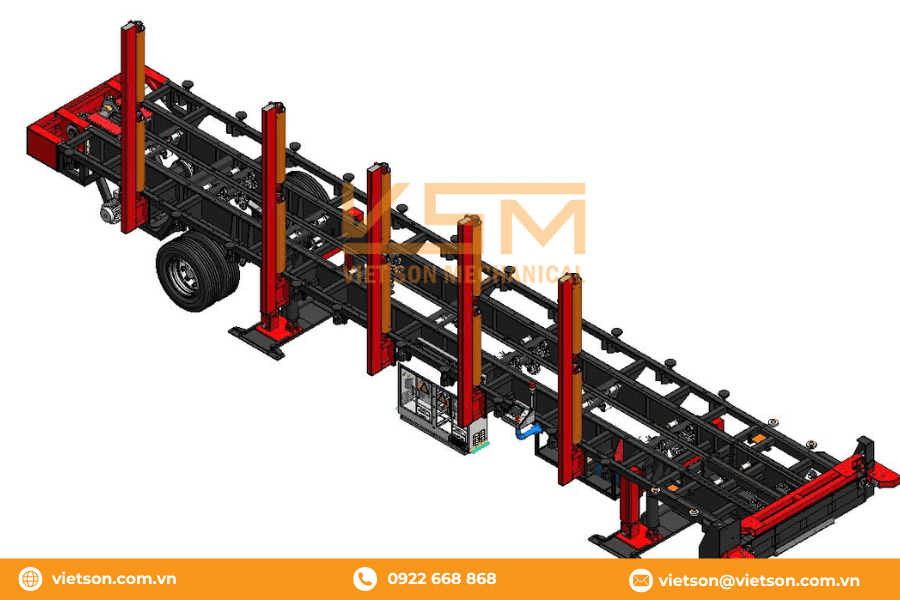

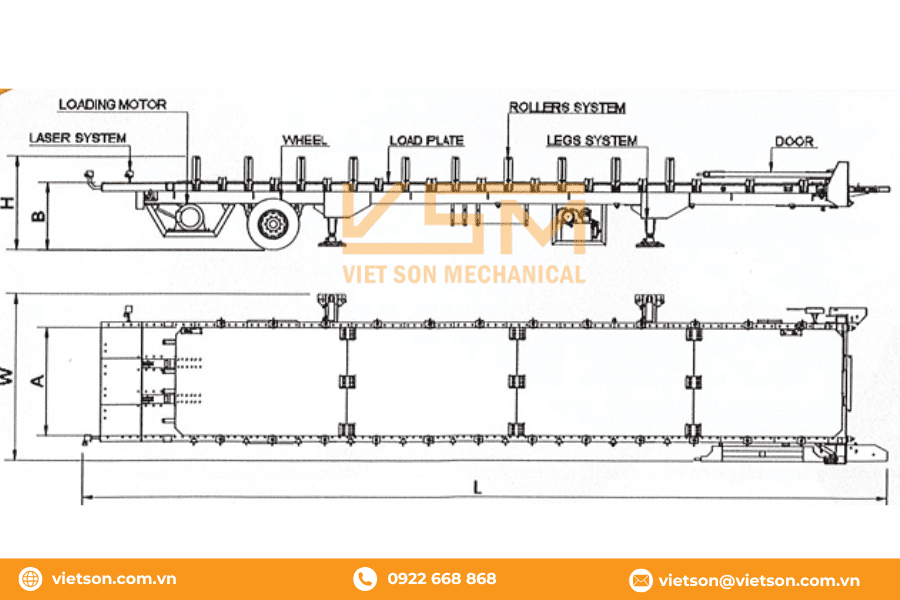

Technical Specifications

| ITEMS | TECHNICAL DATA | |

| Dimensions | LxWxH | 16.2m x 3.4m x 2.1m |

| Loading plate height (B) | 1.45-1.7m | |

| Loading plate width (A) | 2.2m | |

| System’s weight | 17 tons | |

| Power | ~30 kW | |

| Cargo load | 25 tons | |

| Loading plate speed | 5 meters/minutes | |

Structure of the Container Loading System – Viet Son Mechanical

1. Laser System

This component is integrated to align the pushing plate parallel to the container. When properly aligned, the loading process becomes smoother, minimizing impact and reducing the risk of container damage. This system plays a crucial role in enhancing operational accuracy and safety.

2. Loading Motor

The primary driving unit responsible for pushing the loading plate and goods into the container. The motor operates with high power and stability, ensuring fast and smooth container loading.

3. Wheel System

The machine is equipped with heavy-duty wheels that allow easy relocation within the workshop when needed—similar to a semi-trailer design. This mobility enables the machine to be moved between work zones without disassembly or the need for a forklift.

4. Roller System

Comprises high-load-bearing rollers arranged along the surface of the pushing plate. These rollers support and guide goods during loading, minimizing slippage, falling, or misalignment of cargo.

5. Legs System

A height and horizontal adjustment system that accommodates containers of varying sizes. With flexible lifting and positioning capability, it ensures the pushing plate aligns precisely with the container entrance, maintaining system consistency and safety during operation.

6. Door System

Once goods are loaded into the container, the door system is activated to secure the cargo at the container’s front end. This mechanism prevents cargo from shifting or sliding out when retracting the pushing plate and protects the load during transport.

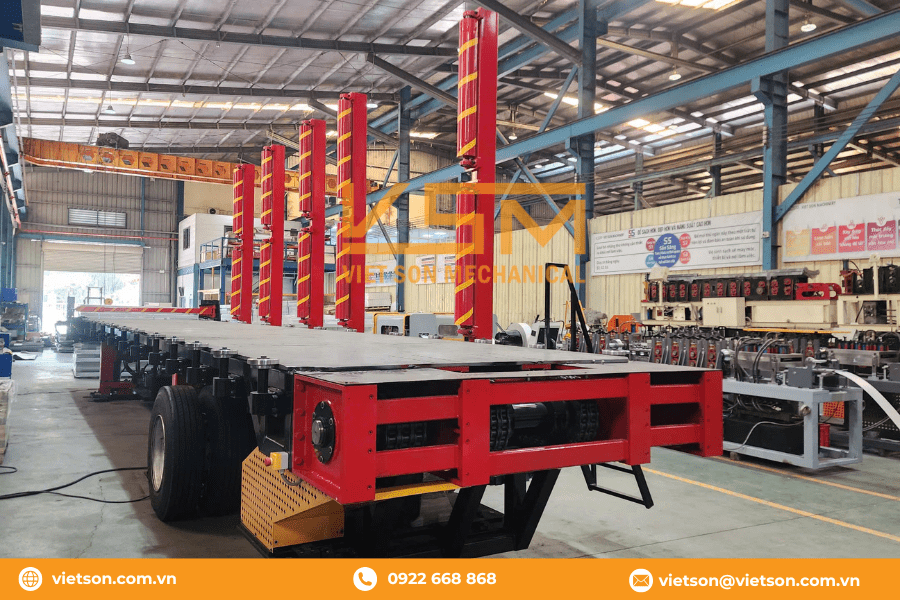

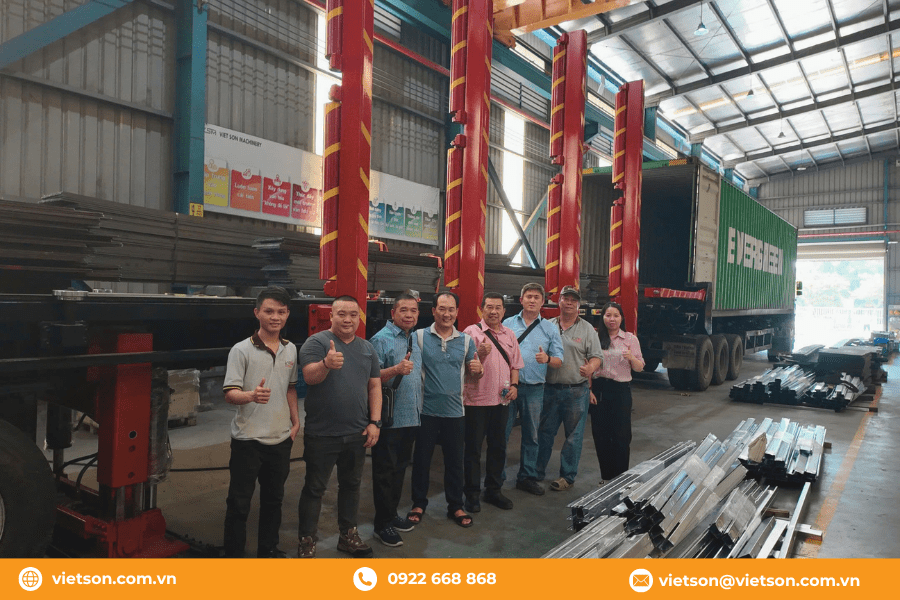

Viet Son Mechanical – Trusted Provider of Container Loading System Solutions

There are many suppliers of loading equipment on the market, but not all understand the logistics challenges or have the capabilities to design tailored systems. Viet Son Mechanical proudly leads the way in designing, manufacturing, and installing Container Loading Systems customized to each client’s specific needs.

Why Choose Viet Son Mechanical?

- Over 15 years of hands-on experience in mechanical engineering and automation.

- Tailored design for each industry – we deliver “made-to-measure” solutions.

- Free on-site consultation and surveys.

- Long-term warranty and nationwide technical support.

- Large-scale in-house manufacturing – no middlemen, ensuring competitive pricing and strict quality control.

Don’t let manual loading slow down your operations, damage goods, or increase hidden logistics costs!

Contact Viet Son Mechanical today to experience a professional, efficient, and cost-saving Container Loading System tailored for your business needs.

Contact Viet Son Mechanical for Detailed Consultation

- Hotline: 0922 668 868 (Zalo – Viber – WhatsApp)

- Factory: Lot C2-7, N7 Street, Tan Phu Trung Industrial Zone, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Office: 253 Dien Bien Phu, Vo Thi Sau Ward, District 3, Ho Chi Minh City

- Website: https://vietson.com.vn/en/

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w