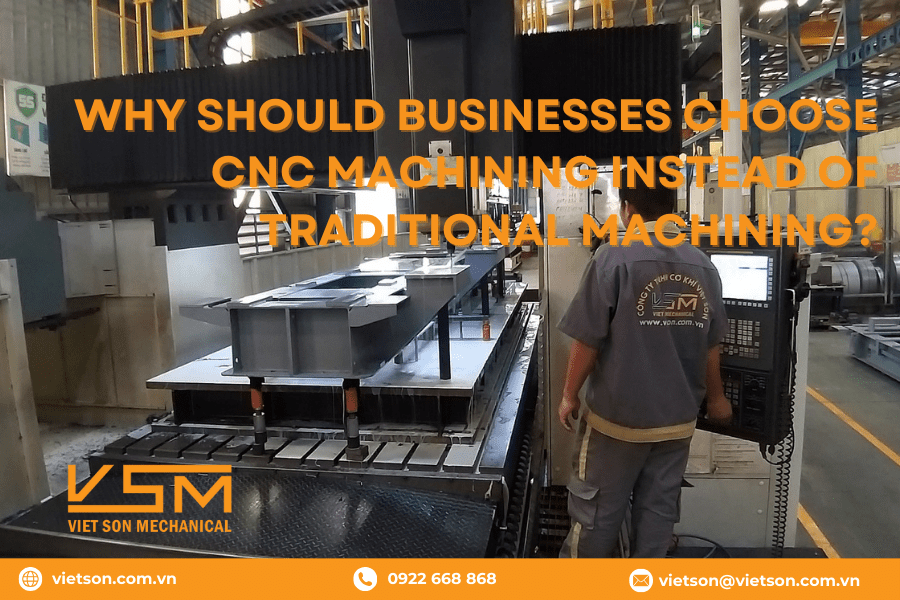

In the modern machining industry, the choice of machining method plays a crucial role in optimizing costs and enhancing product quality. One of the solutions that many businesses currently trust is CNC machining. So why should you choose CNC machining instead of traditional cutting methods? Let’s explore with Viet Son Mechanical through the following article.

-

What is CNC machining? Overview of CNC technology

1.1. Definition of CNC machining

CNC machining (Computer Numerical Control) is a method that uses computer-controlled machinery to cut, turn, mill, and drill materials such as steel, aluminum, and stainless steel… With high precision and automation capabilities, CNC machining is becoming increasingly popular in the mechanical engineering industry.

1.2. The operating principle of CNC machines

CNC machines operate based on the principle of computer-controlled automation. The CNC machining process includes the following steps:

- CAD model design: Use CAD (Computer-Aided Design) software to create detailed product drawings.

- CAM programming: Converting CAD models into G-Code using CAM (Computer-Aided Manufacturing) software.

- Setting up the CNC machine: Load the program into the CNC machine and set the technical parameters.

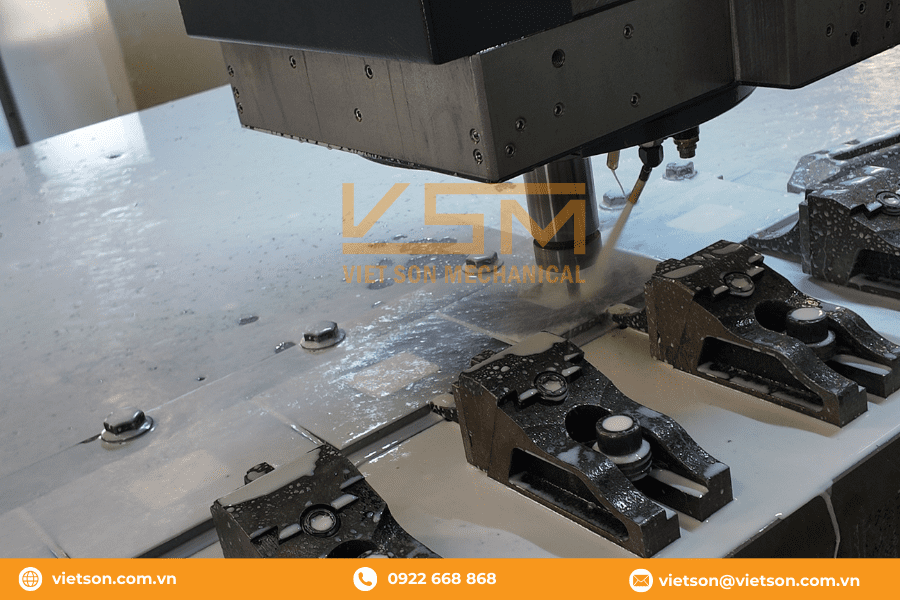

- Automatic machining: CNC machines perform cutting, turning, milling, or drilling processes according to programmed commands.

- Quality control: The product after processing is checked for accuracy and completeness.

1.3. Common CNC machining services at Viet Son Mechanical

- CNC turning is considered an effective method for metal cutting, widely used in the field of mechanical processing. The products of this method are mainly cylindrical, such as smooth shafts, threads, holes, stepped shafts…

- CNC milling is a precision machining method that involves cutting through motion. Milling helps save fuel and has high productivity.

- Laser cutting CNC is a machining method that uses laser technology to cut metal materials such as steel, aluminum, copper, stainless steel, titanium, and many other types of metals.

- Machine manufacturing is the process of designing, producing, and assembling machine parts and components according to the specific requirements of the customer. This process requires high precision, advanced technology, and a team of experienced technicians to ensure the product achieves the best quality.

-

The difference between CNC machining and conventional cutting methods

| Characteristic | CNC machining | Conventional cutting method |

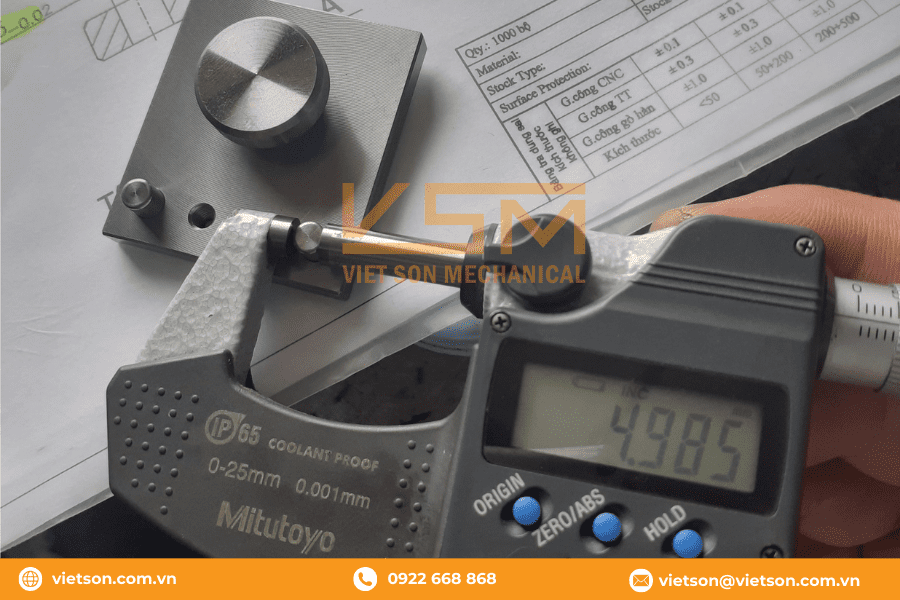

| Accuracy | Extremely small error, can reach ±0.01 mm | Dependent on the skill of the worker, deviations are likely to occur. |

| Processing speed | Fast, stable, can operate continuously 24/7 | Manual, slower speed, dependent on human labor. |

| The complexity of the details | Machining highly complex parts, requiring exquisite technical skills. | Limited to simple, less sophisticated details |

| Automation capability | Completely automated, less dependent on the operator’s skills. | Depends on the experience and skill of the worker. |

| Durability and consistency | Ensure high durability and consistent quality among the products. | It’s difficult to ensure consistency between products. |

| Saving raw materials | Optimizing materials through precise programming capabilities, minimizing waste. | Significant losses due to manual operations |

| Flexibility in production | Easily switch between products just by changing the CNC program. | It takes a lot of time to change the equipment and processes. |

-

The outstanding advantages of CNC machining

3.1. Absolute accuracy

CNC machines have the ability to perform machining operations with an accuracy of up to ±0.01 mm, helping to create exquisite and perfect details. This is very important in industries that require high precision, such as precision mechanics, machine manufacturing, and electronics.

3.2. Increase productivity and save time

CNC machines can operate continuously 24/7 without rest, helping to optimize production time. The automation capability helps shorten processing time compared to manual methods, thereby enhancing the competitiveness of the business.

3.3. Minimizing the risk of errors

Automated machining with CNC machines helps eliminate subjective factors from humans, avoiding errors due to skill level or fatigue during the working process. This ensures that the product quality always meets high and stable standards.

3.4. Diversification of products and materials

CNC machines have the capability to process various materials such as steel, stainless steel, aluminum, copper… At the same time, the machine can perform complex operations such as groove milling, 3D cutting, and contour drilling, ensuring flexibility in production.

-

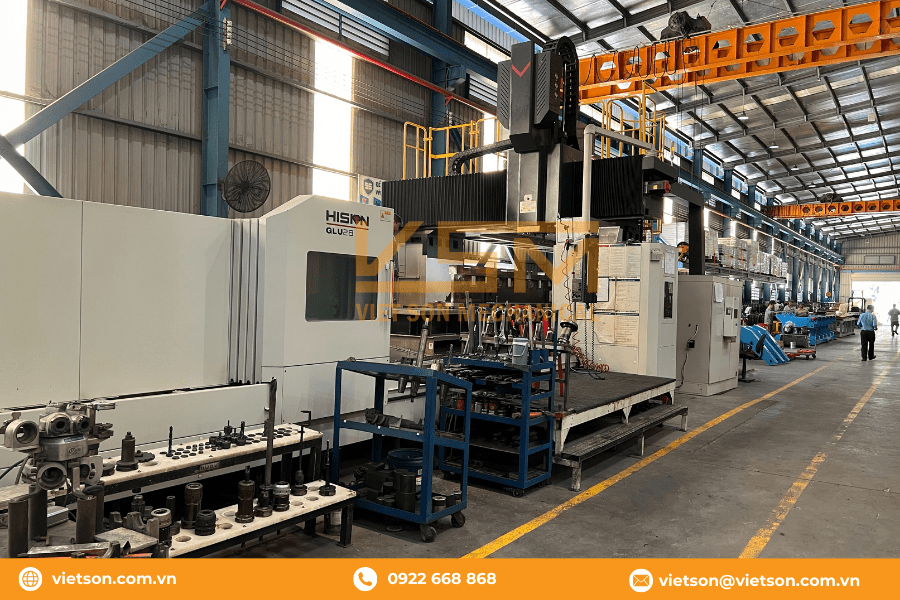

Application of CNC machining services at Viet Son Mechanical

At Viet Son Mechanical Engineering, we take pride in owning a modern CNC machining system that meets all mechanical processing needs, from small orders to mass production. Our team of experienced engineers, along with a strict quality management process, ensures that we guarantee:

✅ The product achieves high precision with a finished surface, without any dimensional deviations.

✅ Quick processing time, timely meeting of customer production needs.

✅ Professional after-sales service, dedicated technical consultation, and regular maintenance.

>>> Learn more: THE BENEFITS OF CNC MACHINING COMPARED TO TRADITIONAL MACHINING METHODS

-

Why choose Viet Son Mechanical as a CNC machining partner?

Modern equipment: Using advanced CNC machines, ensuring optimal performance.

Professional technical team: Proficient in CNC technology and committed to quality.

Competitive pricing: Ensuring reasonable costs, optimizing benefits for customers.

Comprehensive services: Technical consulting, design, and construction upon request.

LARGE MACHINE FRAME PROCESSING AT VIET SON MECHANICS

Contact to book services at Viet Son Mechanical

- Contact for outsourcing: 0922 668 868 (Zalo – Viber – WhatsApp)

- Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, Ho Chi Minh City

- Website:https://vietson.com.vn/en

- Email: [email protected]

- Facebook: https://www.facebook.com/cokhivietson

- Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w