Z purlin – Characteristics, applications and flexibility in practice

Z purlins, with their unique “Z” shape, are not only an important part of building structures but also a symbol of flexibility and efficiency in the construction industry. Below is an introduction to Z purlin and its outstanding features

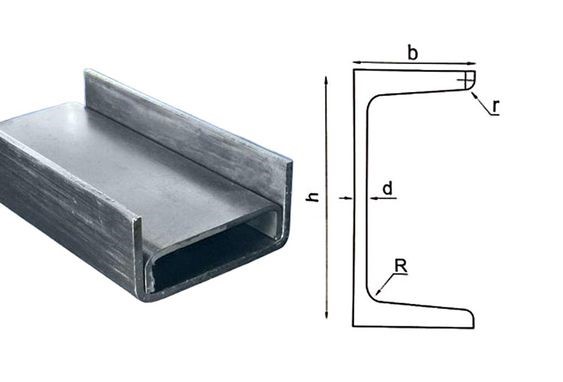

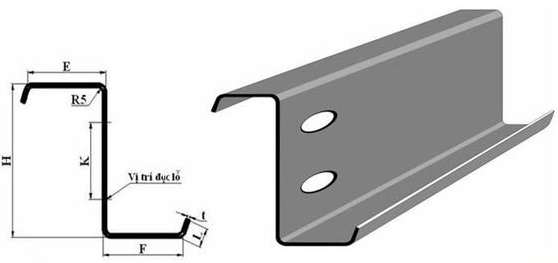

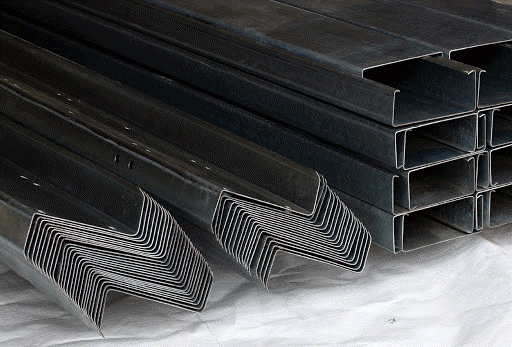

Z purlin and longitudinal section

Z purlin is a type of steel structure shaped like the letter “Z”. It is created from bent steel foil with two parallel edges and a middle edge connecting them, creating a shape that resembles a “Z” tube. Z purlins are commonly used in the construction industry to create columns, beams and structural frames in architectural and industrial projects.

The characteristics of Z purlins are flexibility in design and good load-bearing capacity. With this unique shape, it is often incorporated into construction projects to provide strength and stability to the structure.

1. Typical characteristics of Z purlins

Z purlin – widely used in construction

2.1 Strength and durability

Made from high quality steel, Z purlins provide outstanding strength and durability, helping to ensure stability for projects.

2.2 Flexibility in design

Z purlins are used alternately in the roof frame structure of construction projects

Z purlins not only bear the load but also open up space for creativity in architectural design.3.

3. Wide applicantion

3.1. Factories and industrial workshops

Wide application of Z purlins in industrial factories

In industrial environments, Z purlins serve as important structural components for building factories and workshops. Its load-bearing capacity and flexibility ensure stability for large projects.

3.2 Housing and civil works

On a smaller scale, Z purlins make columns and beams for residential and civil projects, ensuring stability and safety.

3.3 Renewable energy projects

Z purlins have applications in renewable energy projects, supporting the structure of solar power stations or wind rigs.

4. Convenience in installation and processing

4.1 Simple and convenient design

Purlin structure with pre-installed screws and bolts, convenient for installation and dismantling

Z purlins bring convenience in installation and processing, helping to reduce costs and construction time.

4.2 Easy processing

With an easy machining process, Z purlins are an effective choice for construction projects.

5. Why choose Viet Son as a reputable and quality purlin steel processing unit?

5.1. Professionalism and experience

Viet Son is a purlin steel processing unit with a team of experienced experts and technicians. Professionalism in approach to technology and production processes is a commitment to high quality products.

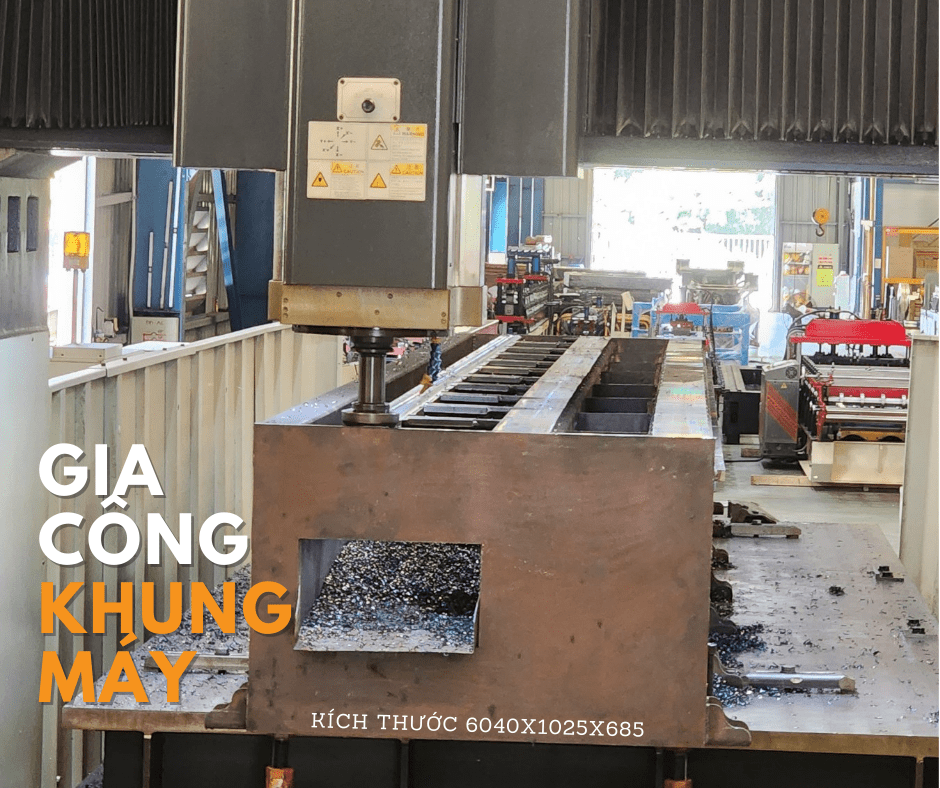

Viet Son Mechanical Provides Leading Mechanical Processing Services in Ho Chi Minh City

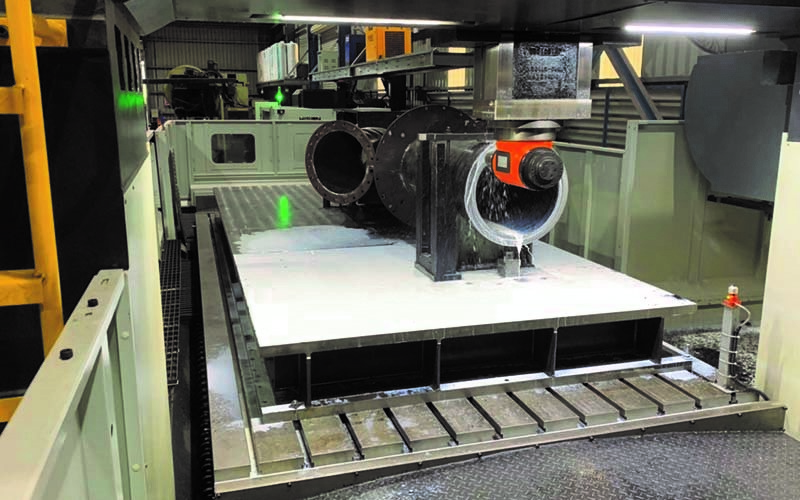

5.2. Modern technology

With strong investment in production technology, Viet Son uses the most modern equipment to process steel purlins. This ensures accuracy and uniformity in every product.

Steel processing process at Viet Son Mechanical

5.3. Strict quality control process

Viet Son implements a strict quality control process from design to production and delivery. This ensures that each product meets or exceeds the highest quality and safety standards.

5.4. Professional consulting services

Viet Son’s customers not only receive quality products but also experience professional consulting services. Our consulting team will support you from material selection to design and production.

5.5. Flexible machining ability

Viet Son has flexible processing capabilities to meet the special needs of customers. Whether projects are large or small, we are committed to providing flexibility and innovation in production.

5.6. Commitment to safety and sustainability

We not only focus on product quality but also put safety and sustainability first. Our products comply with safety standards and are recyclable to reduce their impact on the environment.

Sincerely thank our customers for their trust !

Contact us for more information

Viet Son Mechanical

Hotline: 0898 679797 – 0922 668 868

Email: [email protected]

Facebook: Viet Son Mechanical

Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Cu Chi, Ho Chi Minh City