C Purlins – Effective Solution for Metal Structure Projects

In the field of construction and mechanical engineering, the use of C purlins is becoming increasingly popular, providing effective solutions for metal structure projects. To meet the increasingly diverse needs of the market, C purlin machining has become a smart choice for construction and metal fabrication companies.

1. C purlins and applications in construction

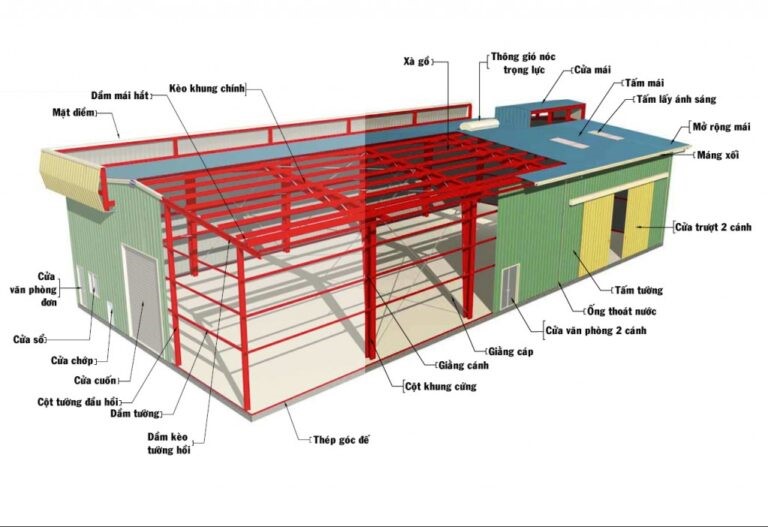

C purlins, also known as C-shaped purlins, are an important component in the field of construction and mechanical engineering. Designed with the shape of the letter “C”, C purlins are widely used in many metal structure projects thanks to their versatility and versatility.

The role of purlins in house structure

2. C purlin characteristics

Purlin processing products C

2.1 Diverse shapes and sizes

C purlins can be made in a variety of sizes and shapes, from small and light to large and strong. This creates flexibility in design and application.

2.2. High quality material

Usually manufactured from high-quality metals such as high-strength steel, C purlins have good load-bearing capacity and durability, making it suitable for projects that require stability and safety.

2.3. Diverse applications

C purlins are used in many fields, including bridge and house construction, factory structures, renewable energy projects, and many other applications. This proves its diversity and flexibility.

2.4. Anti-corrosion features

If properly fabricated and treated, C purlins are corrosion resistant, increasing their ability to maintain shape and durability in harsh environments.

2.5. Advanced machining process

Advances in metal processing technology have optimized the C purlin manufacturing process, from cutting and bending to welding and surface machining, ensuring quality and precision.

3. Application of C7 purlin

3.1. Building bridges and houses

C purlins are used to create load-bearing structures in the construction of bridges and high-rise buildings.

Application of C purlins in roof structure construction

3.2. Factory and factory structure

C purlins are used in the construction of workshops and factories with flexibility in design.

Processing steel structures for Light Frame houses

Model of steel configuration processing, using cross beams

3.3. Solar project

In renewable energy projects, C purlins support the installation of solar panels and other equipment.

4. Advantages of projects using C purlins

4.1. Durability and strength

C purlins are machined from high quality metal materials, providing excellent bearing capacity and durability. This makes them the preferred choice for projects that require stability and safety.

4.2. Flexibility in design

Prefabricated houses, the trend of building convenient, aesthetic, and solid houses in 2023

The C purlin machining process offers great flexibility in design and shaping, helping to meet specific project requirements. This allows for products of diverse shapes and sizes.

4.3. Save time and costs:

House with purlin roof structure C

Processing C purlins through modern technologies helps optimize the production process, thereby reducing time and costs compared to free production. Average assembly time through screw connections Pre-machined screws of C purlins save construction and assembly time compared to conventional houses.

4.4. Quality guaranteed

Professional machining units often use high quality control machinery and processes, ensuring C purlins meet technical standards and requirements.

Steel structure purlins in civil housing construction

4.5. Adaptation to the environment

With good corrosion resistance and bearing capacity, C purlins adapt well to harsh environments, ensuring long life and performance.

5. Why should you process shaped steel at Viet Son Mechanical?

Viet Son Mechanical is a reputable and quality shaped steel processing unit for the following reasons:

Modern machinery and equipment: Viet Son Mechanical is equipped with modern machinery and equipment to perform shaped steel processing effectively and with quality. This can ensure that the final product meets specific technical requirements and standards.

Viet Son mechanical processing workshop

High precision: Using advanced machinery and technology, Viet Son Mechanical has the ability to work with high precision, helping the final product have accurate dimensions and characteristics.

Meet large output: Viet Son Mechanical has the ability to meet large output, this is especially important if you have a large order or need to mass produce products.

Fully certified materials: Viet Son Mechanical is capable of providing quality certified steel materials, ensuring that your products comply with safety and quality standards.

Guaranteed on schedule: Viet Son Mechanical can commit to the project’s schedule and ensure that your order will be completed on time, this is especially important in construction and industrial production.

Viet Son is a trusted destination for customers in the field of mechanical processing and steel structures

Prestige and quality: Viet Son Mechanical has a reputation in the metal and steel processing industry, and they are recognized for the quality of their products and services.

Being the leading unit in Vietnam in designing, manufacturing, and processing high quality metal rolling with diverse designs and types according to customer requirements. For many years, Viet Son Mechanical has continuously invested and developed to meet the increasing demand for mechanical services of customers. For the most accurate and detailed quote, please contact hotline 0898 679797 or send information to email [email protected]

Sincerely thank our customers for their trust !