Steel plate, a highly essential material in both the industrial and construction sectors, plays a pivotal role in building infrastructure and manufacturing numerous vital products. If you are seeking reliable and high-quality steel plate processing services, continue reading this article as Viet Son Mechanical Engineering introduces you to the processes and pricing for steel plate processing.

What is steel processing?

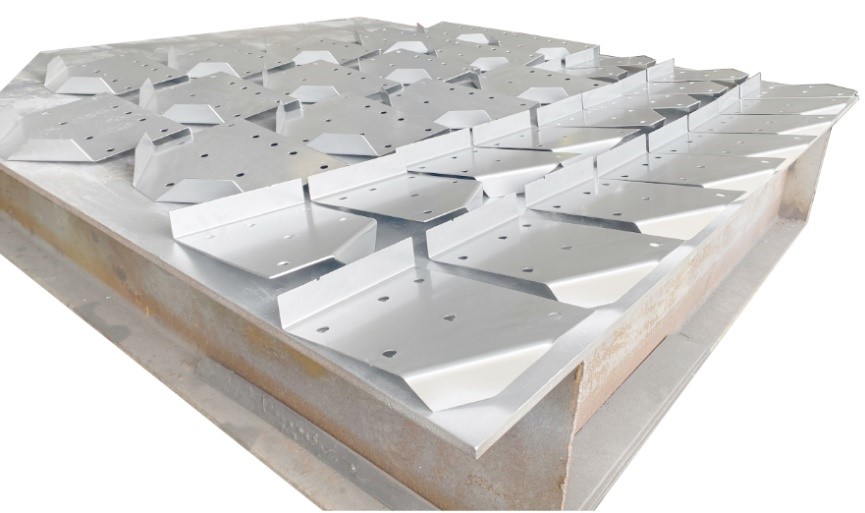

Steel plate processing is the transformation of hot-rolled or cold-rolled steel sheets from raw materials into steel plate products with specific dimensions, shapes, and quality according to customer requirements or production standards. This processing journey involves various stages such as cutting, angle cutting, bending, plasma cutting, grinding, or galvanizing, depending on the ultimate purpose of the steel plate product.

The steel plate processing aims to fabricate diverse steel components, products, or structures, including floor plates, cladding panels, wall panels, structural frames, machine parts, and numerous applications across the industrial and construction sectors. This process demands precision and stringent control to ensure that the final product meets technical specifications and quality standards.

Steel plate processing methods

There are various methods of steel plate processing tailored to specific requirements. Let’s explore some common and widely chosen methods :

Laser Cutting of Steel Plates

- Description: Laser cutting of steel plates is a high-intensity laser light process used to precisely and sharply cut steel plates into desired shapes and sizes.

- Advantages: High precision, can cut complex shapes, does not generate high temperatures, reduces deformation and does not require contact tools.

- Application: Creating machine parts, frames, and complex mechanical products.

Steel plate bending

- Description: Steel plate bending is the process of bending steel plates to create required angles or bend shapes.

- Advantages: Creating a structure and framework that allows for flexibility and enhances the strength of steel products

- Applications: Used in the manufacturing of bridges, roofing sheets, and the structural framework for infrastructure.

Punching holes in steel plates

- Description: Hole punching is the process of creating round holes or other shapes in steel plates using punching tools or machine tools.

- Advantage: Creates mounting holes, through wires, tubes, etc., helps in assembling and connecting parts.

- Application: Manufacturing parts in the automotive industry, manufacturing electrical cabinets, assembling lighting systems and many other applications.

Steel Plate Forming to Specifications

- Description: Stamping is the process of using pressure to create shapes or details on steel plates.

- Advantages: Creates high precision parts and the ability to reproduce large quantities of products.

- Application: Production of mechanical parts, machine parts, etc

Bending Steel Plates

- Description: Steel plate bending is the process of changing the shape of a steel plate by bending it into different angles or curves as required.

- Advantages: Creates curved products such as tubes, bent tubes, and many products with complex shapes.

- Application: Production of products with curved and bent shapes such as tubes, bent pipes, bent frames.

Each machining method has its own properties and advantages, and the choice depends on your project’s specific requirements and ultimate goals.

Machinery and equipment for processing steel plates

Below are some types of machinery and equipment used to process steel plates :

Processing steel plates with laser machines

This machine uses laser light to precisely and sharply cut steel plates into desired shapes and sizes. It has the ability to cut curves and create holes in steel plates

Processing by steel plate cutting machine

This cutting machine uses cutters or saws to cut sheet steel into elements or sub-plates according to specific dimensions. It is suitable for cutting steel of different thicknesses.

Processing by punching machine

This punching machine is designed to make round or other shaped holes in steel plates. It uses pressure to punch holes and create holes with a specified size and distance.

These machines and equipment are used in steel plate processing factories to ensure accurate and efficient machining processes. The choice of specific machinery depends on the type of machining job, the technical requirements of the final product, and the source of raw materials used.

Quotation for steel sheet processing

| Price list for steel sheet processing upon request | |||

| PRODUCTION REQUIREMENTS | ĐVT | ĐƠN GIÁ | |

| 1 | Processing steel sheets | Kg | Contacts |

| 2 | Pipe processing + welding | Kg | Contacts |

| 3 | Processing V-shaped steel bending | Kg | Contacts |

| 4 | Processing U-shaped steel bending | Kg | Contacts |

| 5 | Processing Z-shaped steel bending | Kg | Contacts |

| 6 | Processing and stamping of stairs | Kg | Contacts |

| 7 | Processing steel plates to make scales | Kg | Contacts |

| 8 | Processing and cutting of code plates | Kg | Contacts |

| 9 | Flange cutting processing | Kg | Contacts |

| 10 | Discharge long rolls as required | Kg | Contacts |

| 11 | Punch holes, cut holes | Hole | Contacts |

Why should you process steel plates at Viet Son mechanical engineering?

- Diverse Services: Viet Son Mechanical provides a wide range of steel sheet processing services such as cutting, bending, bending, stamping, and punching. This gives customers flexibility in creating products of desired shapes and sizes.

- Modern Machinery Equipment: Viet Son Mechanical is equipped with modern machinery and equipment with high precision, helping to ensure product quality and diverse processing capabilities.

- Clear Origin: Steel plates at Viet Son Mechanical have clear origins and come with quality certificates such as Certificate of Origin (CO) and Certificate of Quality (CQ). This ensures that the product is made from high quality raw materials.

- High Precision Products: Products processed at Viet Son Mechanical have high precision and good aesthetics. This ensures that the final product meets the customer’s technical and aesthetic requirements.

- Meet High Productivity: With modern equipment and experienced staff, Viet Son Mechanical is capable of meeting high productivity and output, while ensuring accuracy and quality.

- Experienced Personnel Team: Viet Son Mechanical has a team of experienced personnel in the industry. The people working here have the necessary knowledge and skills to ensure the machining process takes place efficiently and with quality.

In fact, steel plate processing is an important and indispensable process in many industries and construction. With a variety of machining methods, along with the combination of modern machinery and experienced personnel, manufacturing and construction projects can achieve precision, quality, and High performance. Choosing a reliable partner in the field of steel sheet processing like Viet Son Mechanical can help you ensure that your products meet all requirements and quality standards.