Custom steel processing plays a decisive role in many industries. Creating quality steel products and meeting customer requirements requires precision, high technique and a deep understanding of the properties of this material. In this article, let’s join Viet Son Mechanical to learn about the steel processing process, materials, processing methods and price list for steel processing according to current requirements.

What is custom steel processing?

Custom steel fabrication (also known as custom metal fabrication) is the process of manufacturing steel or other metal products based on specific customer requirements. Instead of producing standard products in large quantities, custom steel fabrication focuses on creating products with specific dimensions, shapes, and properties according to the customer’s preferences.

This process begins with designing the product based on customer requirements and then utilizes various fabrication methods such as cutting, bending, welding, grinding, polishing, or numerous other processes to create the final product. Custom steel fabrication is highly significant in many industries, including construction, manufacturing, automotive, aerospace, and various others, where products need to meet specific requirements regarding dimensions, precision, and physical properties.

The use of custom steel fabrication ensures that the final product meets the specific requirements of the customer while minimizing waste and optimizing production efficiency.

Materials for custom steel fabrication

Ensuring the appropriate material selection is a crucial factor in custom steel fabrication to ensure that the final product meets the specific requirements of the project or application.

Below are some common types of materials used in custom steel fabrication:

Stainless steel (Inox)

Stainless steel, also known as corrosion-resistant steel, is used in applications that require corrosion and oxidation resistance, such as medical equipment, the food industry, and the chemical manufacturing industry.

Galvanized steel

Galvanized steel, also known as zinc-coated steel, is used to protect steel from corrosion. It is commonly employed in construction, automotive manufacturing, and outdoor applications.

Alloy steel

Alloy steel is a type of steel that incorporates additional alloys, such as chromium, nickel, manganese, to enhance mechanical properties or corrosion resistance. It is commonly used in industries such as aerospace, manufacturing, and construction.

Carbon steel

Carbon steel is a type of steel that contains a relatively high amount of carbon and few alloying elements. It is widely used in various industrial applications, including mechanical construction, structural engineering, and many other applications. The choice of material depends on the specific requirements of the project, including the working environment, mechanical properties, corrosion resistance, and many other factors. It is crucial to be cautious when selecting materials to ensure that they are suitable for the goals of custom steel processing

Current Custom Steel Processing Methods

At present, various custom steel processing methods are employed to manufacture complex metal products. Here are some common methods:

Laser cutting

Laser cutting utilizes an intense laser beam to precisely and rapidly cut steel. This method is well-suited for cutting intricate shapes and reduces material deformation.

Plasma cutting

Plasma cutting uses a high-temperature plasma arc to cut through steel. It is suitable for cutting thick steel quickly.

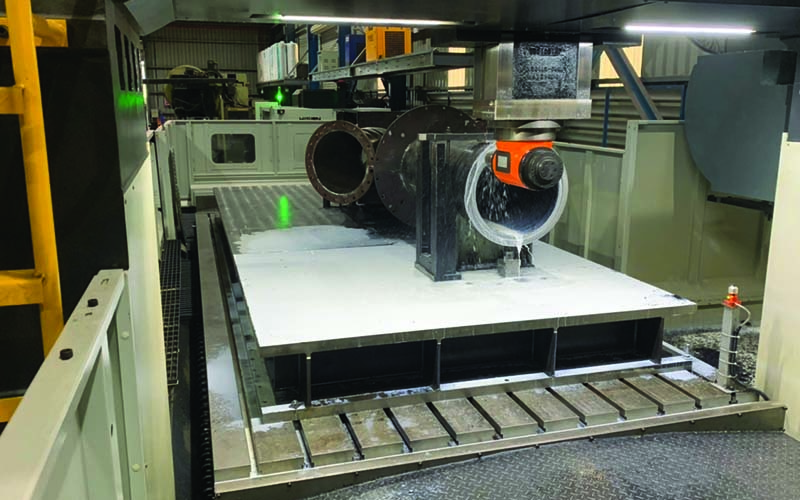

CNC Machining (Computer Numerical Control)

CNC machining utilizes computer-controlled machines to process steel. This enables the production of high-precision products with ease of repeatability.

Bending

Bending is the process of shaping steel using a press brake or bending machine. It is suitable for creating details with curved or folded shapes

Welding

Welding is the process of joining pieces of steel together. There are various welding methods, including arc welding, MIG welding (Metal Inert Gas), and TIG welding (Tungsten Inert Gas).

Polishing and Finishing

Polishing and finishing involve the surface grinding process to remove unevenness and irregularities on the metal surface. Subsequently, coating or heat treatment can be applied to achieve the desired finished surface.

Galvanizing

Galvanizing is the process of coating a layer of zinc onto the surface of steel to protect it from corrosion. This is commonly used in outdoor products or applications requiring high corrosion resistance.

Heat Treatment

Heat treatment is the process of adjusting the crystalline structure of a metal to enhance its mechanical properties, such as hardness and ductility. This is often used in the production of products requiring specific mechanical properties.

These steel processing methods are often combined and customized to create products according to customer requirements or specific project specifications.

Steel processing process

The steel processing process is a series of technological steps carried out to manufacture products from steel or other metal alloys. Below is an overview description of the steel processing process, including the main steps:

- Product Design: The first step in the steel processing process is designing the product. This involves determining the dimensions, shape, physical, and mechanical properties of the product based on customer requirements or specific project needs. Design can be done using CAD (Computer-Aided Design) software to create technical drawings.

- Material Selection: After the design is complete, the process involves choosing suitable materials such as steel, stainless steel, alloy steel, or others based on the properties and requirements of the product.

- Cutting: The steel material is cut into smaller parts based on the design drawing. Cutting can be done using plasma cutting, laser cutting, or mechanical cutting, depending on specific requirements.

- Processing and Bending: After cutting, steel pieces can be processed to achieve the desired shape and structure using machining tools such as lathes, presses, and bending machines.

- Welding: The processed parts are then welded together to form the final product. The welding process may use arc welding or MIG welding (Metal Inert Gas) depending on the product’s requirements and characteristics.

- Grinding and Finishing: After welding, the product may undergo grinding and finishing to remove unevenness and irregularities on the surface, as well as to create a polished surface or a specific finished surface layer if needed.

- Quality Inspection: Finally, the product is subjected to quality inspection to ensure it meets specific requirements and standards. This includes checking dimensions, mechanical properties, and other product requirements.

- Packaging and Delivery: Lastly, the finished product is packaged and delivered to the delivery location or installed if necessary.

The steel processing process may vary depending on the type of product and specific project requirements, and it may include additional steps such as galvanizing, coating, or heat treatment.

Reputable on-demand steel processing unit

Viet Son Mechanical is a reputable steel processing unit in Vietnam, well-known in the mechanical industry. With over a decade of operation, Viet Son Mechanical has built a strong reputation for product quality and professional services.

- Highly skilled technical team: Viet Son Mechanical boasts a team of skilled technicians with expertise and experience in the field of mechanics and metal processing.

- State-of-the-art equipment: The company owns modern equipment and machinery, including milling machines, laser cutting machines, and CNC machining machines, enhancing production capabilities and ensuring precision.

- Quality and reliability: Viet Son Mechanical consistently adheres to strict quality standards and conducts product quality checks before delivery, ensuring reliability.

- Diverse clientele: Viet Son has collaborated with numerous clients across various industries, from construction to manufacturing, showcasing its ability to meet diverse requirements.

In summary, customized steel processing plays a crucial role in many industrial and construction sectors. Viet Son Mechanical, with its advanced steel processing methods, ensures that the final products meet technical standards and quality. Contact Viet Son Mechanical for a quote on customized steel processing!