In the housing construction industry, innovation lies not only in modern design but also in the use of advanced materials and technology. One of the notable trends is the emergence of Omega purlins, which offer unique opportunities and benefits for the construction process and quality of life.

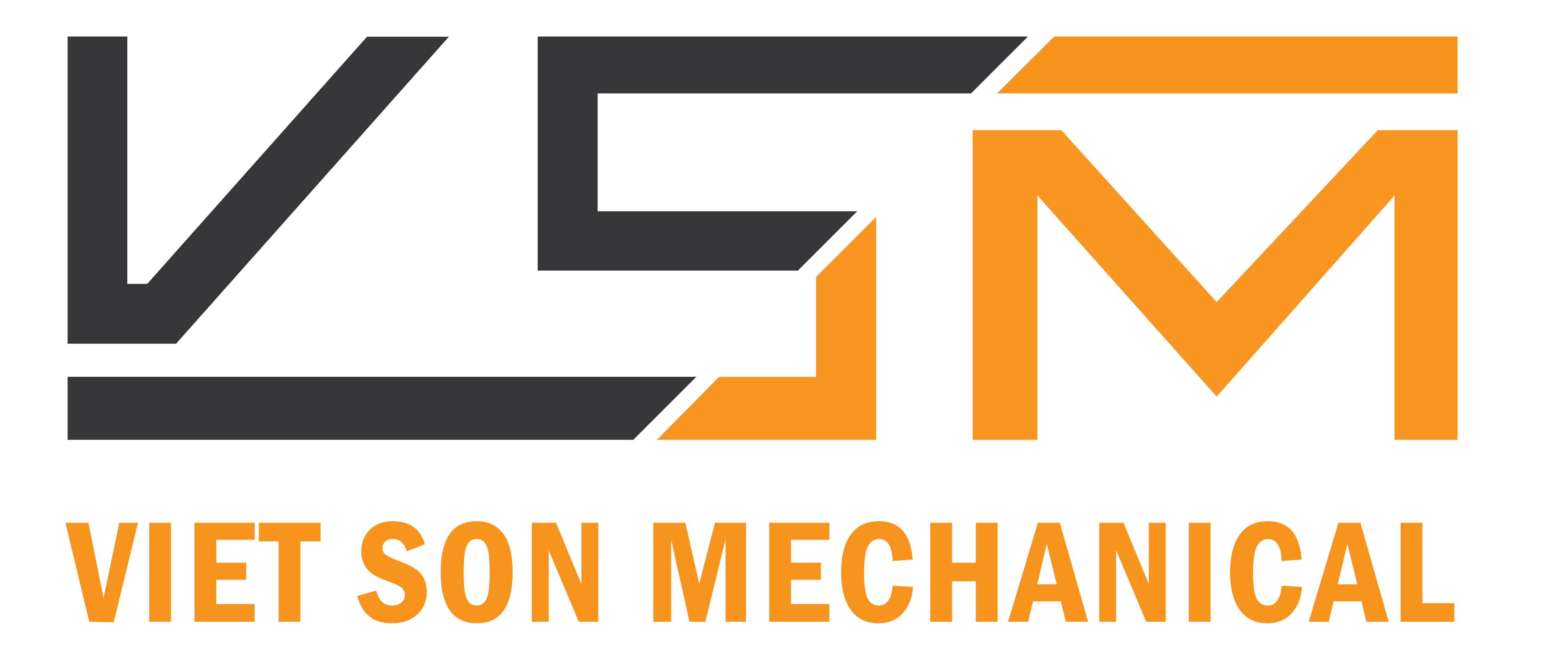

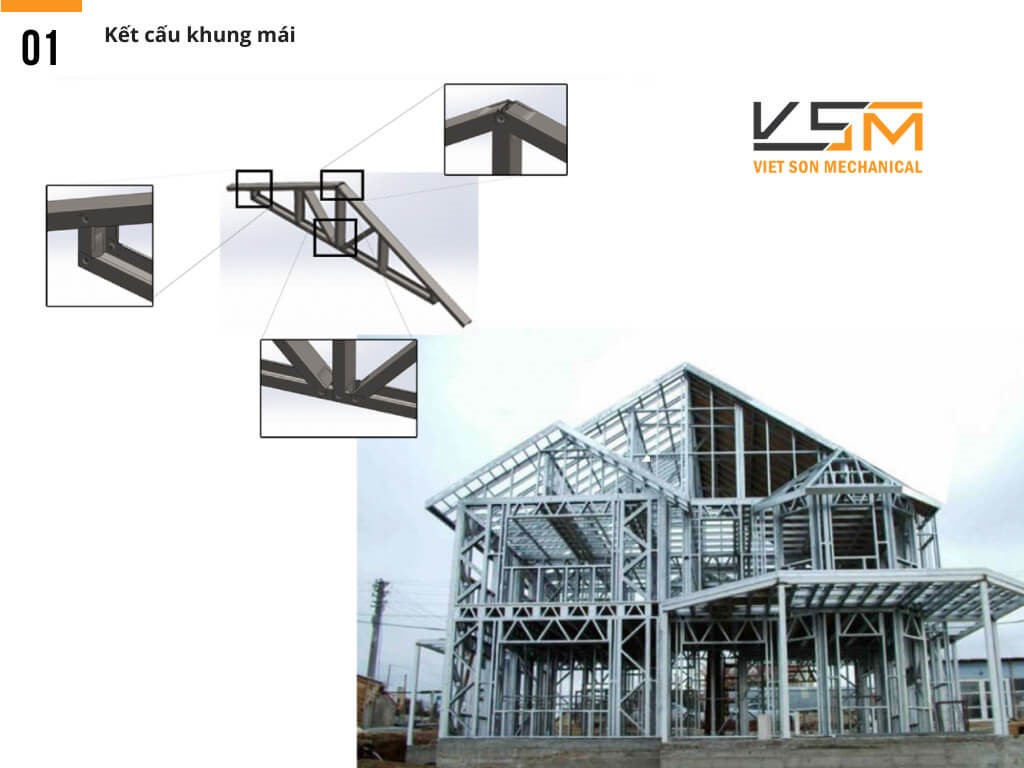

Roof structure in the housing construction model

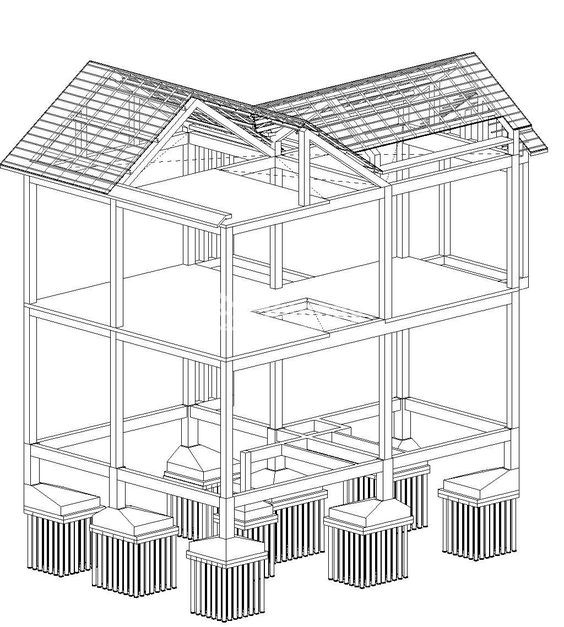

1. What is Omega purlin

Omega purlin

Omega purlins are a term commonly used in the construction industry to describe steel bars shaped like the letter “Ω” (Omega) when viewed from above. Omega purlins are often used as the main component of steel structures in construction projects.

The role of Omega purlins in the roof frame structure

The “Ω” feature of Omega purlins provides many benefits during construction, including good bearing capacity, design flexibility, and stability during installation. Omega purlins are often made from high quality steel and are corrosion resistant to ensure sustainability and safety of the construction structure.

With high stability, Omega purlins are often used as secondary purlins in multi-layer roof structures, acting as load-bearing and as an intermediate part between layers of corrugated iron.

2. Advantages of Omega purlins in housing and construction projects.

2.1 Good strength and lightweight

Omega purlins, with their sturdy steel structure, provide good bearing capacity while still remaining light in weight. This helps reduce the burden on columns and beams, optimize the structure and reduce pressure on the foundation.

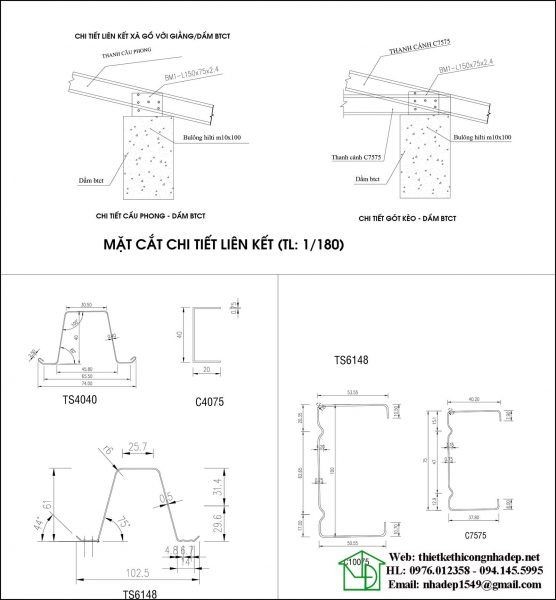

Omega purlin cross section and purlin connection with bracing

2.2 Resilience and shock absorption

With its elasticity, Omega purlins help reduce vibrations and vibrations in bad weather conditions or when there is an external force. This increases the safety and stability of the entire steel structure system.

2.3 Anti-Influence from the environment

Omega purlins are often machined with anti-corrosion and crack-resistant materials, helping to increase the lifespan of the steel structure in harsh environmental conditions. This is especially important when building in areas with high humidity or where exposed to marine environments.

2.4 Easy Installation and time saving

Residential roofs and Omega purlins

Omega purlins are often pre-produced in standard sizes and lengths, minimizing the time and effort required for the installation process. This brings higher work efficiency and minimizes the possibility of errors during construction.

Steel structure construction with Omega purlins

Using Omega purlins in steel structure construction not only brings immediate benefits but is also an investment in a sustainable future. Purlins are manufactured from recycled and recyclable materials, helping to reduce waste and negative impact on the environmen

3. Advantages of projects using omega purlins

Constructions using Omega purlins bring many technical, economic, and environmental advantages. Here are some important advantages:

3.1 Durable

Omega purlins are made from high quality steel, providing high bearing capacity and durability, making the structure of the project strong and stable.

3.2 Design flexibility

The “Ω”-like shape of Omega purlins creates design flexibility, allowing for creativity and diversity in architectural design.

Omega purlins are often made with anti-corrosion and crack-resistant materials, increasing their resistance to environmental influences.

The light weight of Omega purlins reduces pressure on the foundation and foundation, reducing the burden on the foundation structure.

3.3 Save costs and installation time

Convenient during project installation

The uniformity in size and shape of Omega purlins helps save time and costs during installation.

3.4 Shockproof and resilient

Omega purlins are anti-shock and elastic, helping to reduce shock in case of impact from the surrounding environment.

3.5 Increase the life of the construction

Corrosion and crack resistance helps increase the lifespan of the structure, reducing maintenance and regeneration costs in the long term.

3.6 Compatible with modern construction technology

Modern housing projects use omega purlins for the roof frame structure

Omega purlins are compatible with modern construction technologies, helping to optimize the construction process and ensure accuracy in construction..

The design flexibility of Omega purlins helps create unique and aesthetic projects, increasing the market value of the project.

4. Viet Son – The leading processing unit in the Vietnamese market

Viet Son Mechanical is one of the leading units in the field of mechanical processing in Vietnam. In order to meet the increasing demands of the market, Viet Son always focuses on investing in machinery and equipment with advanced technology that can meet CNC machining according to customer requirements.

Viet Son Mechanical has a team of professional engineers, modern CNC machinery systems and dedicated after-sales service. We are ready to bring customers processed products of high quality and outstanding performance.

For advice on CNC machining and ordering quotes. Please leave your information or contact us immediately via hotline 0922 868 868 – 0922 668 868.

Sincerely thank our customers for their trust!