Machine parts processing is a critical field that requires professional technical expertise and should be operated by skilled engineers or individuals with good specialization, as the resulting products are highly complex. So, what is machine parts processing, and why should you choose Viet Son Mechanical Company as your partner instead of other businesses? Let’s find out below!

What is machine parts processing?

Machine parts processing is a method that applies advanced techniques, utilizes the support of information technology machinery, and employs mechanical processing skills to transform raw materials into detailed machine parts. The finished products, after processing, will have precise dimensions, smooth surface finishes, and high accuracy down to the smallest details. According to Fortune Business Insights, the estimated value of the precision machining industry is projected to reach $140.78 billion by 2029, with a compound annual growth rate of 7.1%.

Applications of Machine Parts

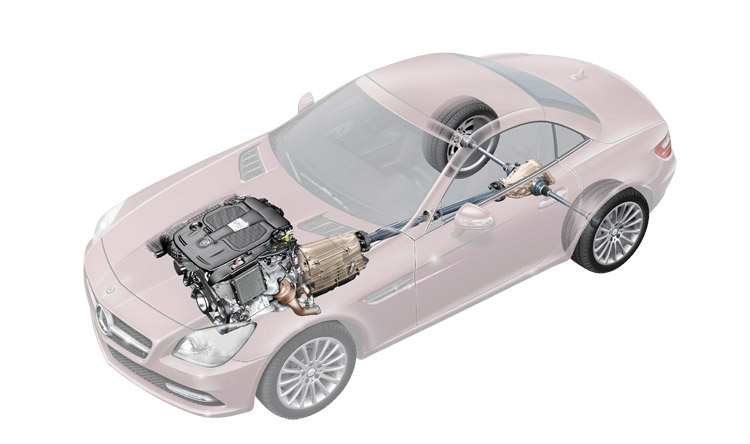

Machine parts, which are widely used and easily visible in our daily lives, can be found in various objects and tools. These machine parts come in diverse shapes, ranging from simple to complex, and are applied in many fields, particularly in aviation, maritime, industrial, and military sectors.

The most commonly encountered types of machine parts include gears, bolts, nuts, and springs.

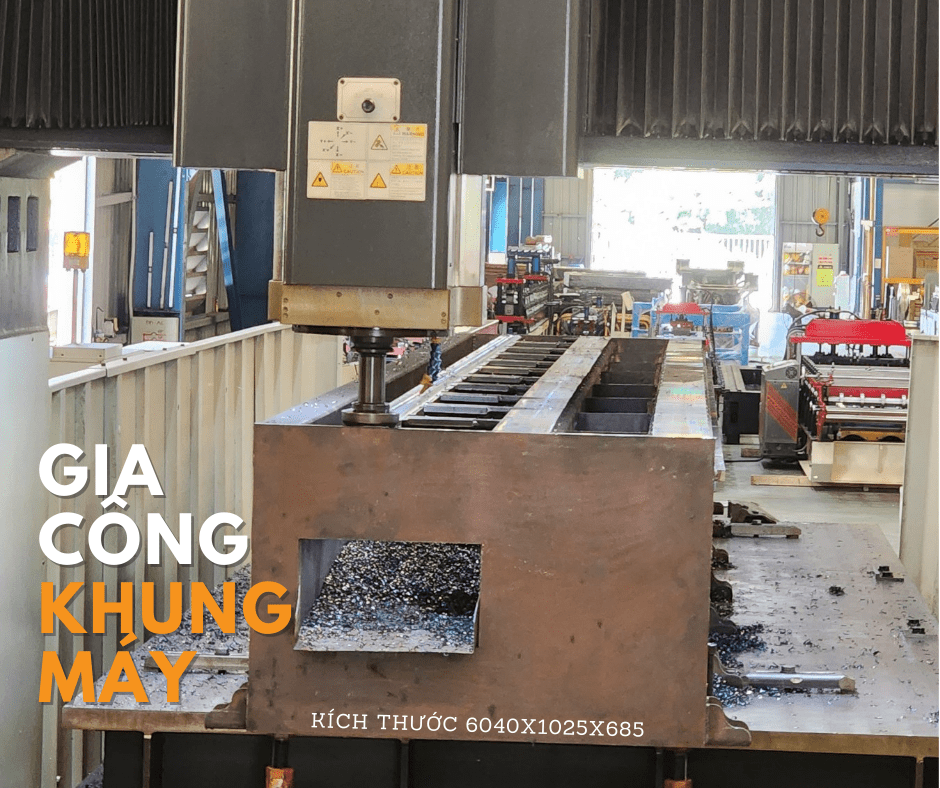

Machining Methods at Viet Son for Machine Parts

CNC Milling Machining

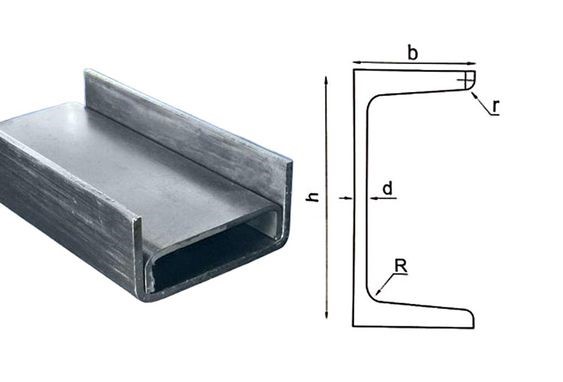

CNC milling machining is a precise mechanical machining method that involves cutting and shaping materials using the movements of machines. The application of CNC milling machining in production helps save fuel and ensures high productivity. This machining method is widely used for various purposes, including flat surface machining, grooving, contouring, and other complex geometries.

CNC Turning Machining

CNC turning machining is a process that involves rotating the workpiece on an axis and performing various stages such as cutting, grinding, and drilling, using tools such as turret lathes and engine lathes. In more complex operations, this machining method also utilizes techniques such as facing, taper turning, external threading, and thread cutting.

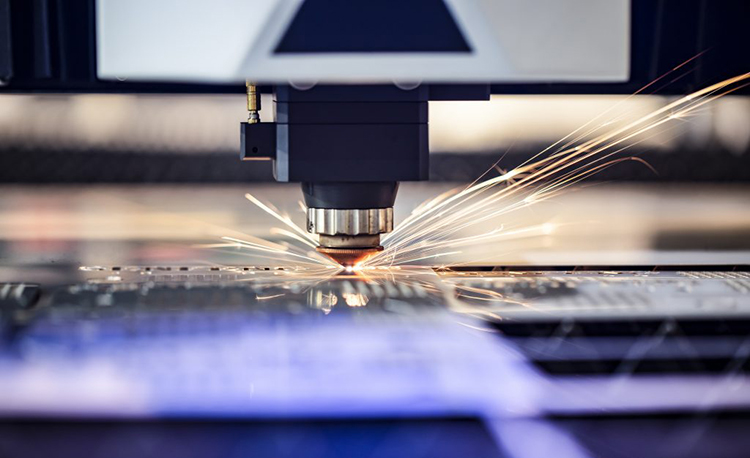

CNC Laser Cutting Machining

CNC laser cutting machining is a method of cutting metal materials into desired 2D or 3D shapes. With the application of modern machinery technology, CNC laser cutting machining enables the production of unique and diverse products.

Pricing for machining services at Viet Son

Each machining service for machine parts will vary in size, material, and complexity. Therefore, please contact Viet Son to receive the most accurate pricing.

| Machining Method Pricing | Quote |

| CNC milling machining | 5-8 million VND per machine per 8-hour shift |

| CNC turning machining | 5-8 million VND per machine per 8-hour shift |

| CNC laser cutting machining | 5-8 million VND per machine per 8-hour shift |

The machining process of machine parts at Viet Son

Step 1: Reception and design of 2D, 3D drawings according to customer requirements Customers can directly submit their machining requests to our company or send them via email. In case customers seek advice on the machining process, our team of engineers will collaborate with them to develop the concept and design the drawings based on the required dimensions. Subsequently, the engineers will finalize the 3D drawings using specialized software.

Step 2: Determining the production format: single-piece production, batch production, or mass production There are three basic formats:

- Single-piece production: involving a very limited number of products per year, usually ranging from one to several dozen pieces, with no production cycle.

- Batch production: involving a relatively large annual production output, with products being processed in batches according to a defined cycle.

- Mass production: involving large-scale continuous production.

Step 3: Selecting suitable machining stock materials Viet Son will provide guidance to customers in choosing the appropriate stock materials based on the size and requirements of the products to be machined. Alternatively, this step can be skipped if customers have already chosen suitable materials. Opting for suitable stock materials helps customers reduce material and machining costs, improve productivity, and lower product costs.

Step 4: Sending a quotation, signing the machining contract After finalizing the plan and machining timeline, Viet Son will proceed to sign the contract with the customer to ensure the rights and benefits of both parties.

Step 5: Establishing a comprehensive machining process For each different machine part, there will be a distinct machining process. Depending on the customer’s machining requirements, we will propose the most suitable and efficient machining process.

Step 6: Machining the parts using modern CNC machinery The parts will be machined using state-of-the-art CNC machinery, ensuring accuracy for each component.

Step 7: Post-machining product inspection The products will undergo dimensional inspection using specialized tools such as calipers, micrometers, 2D and 3D measuring devices. Additionally, the products will be checked for accuracy and surface finish according to technical requirements.

Why choose Viet Son Mechanical Engineering?

The process of machining machine parts may seem simple, but errors can occur during the design and manufacturing stages.

Viet Son Mechanical Engineering is one of the leading professional machining companies in the market, trusted by many customers for its professionalism and high-quality products.

With an experienced team and a commitment to quality, each product undergoes thorough quality checks before leaving the factory. For any inquiries or concerns, customers can contact us via:

- Hotline: +84 898 679797 – +84 922 668 868.

- Address: Lot C2-7, N7 Street, Tan Phu Trung Industrial Zone, Cu Chi District, Ho Chi Minh City.

- Fanpage: Viet Son Mechanical Engineering.

- YouTube: Viet Son Mechanical Engineering.