What is shaped rolled steel processing?

Rolling metal shaped steel is the process of using the pressure of a rolling machine to change the shape of shaped steel, from the original billet form into the desired product form. This process can be performed on many different types of steel sections, including hot rolled steel, cold rolled steel, etc.

Application of metal shaped steel

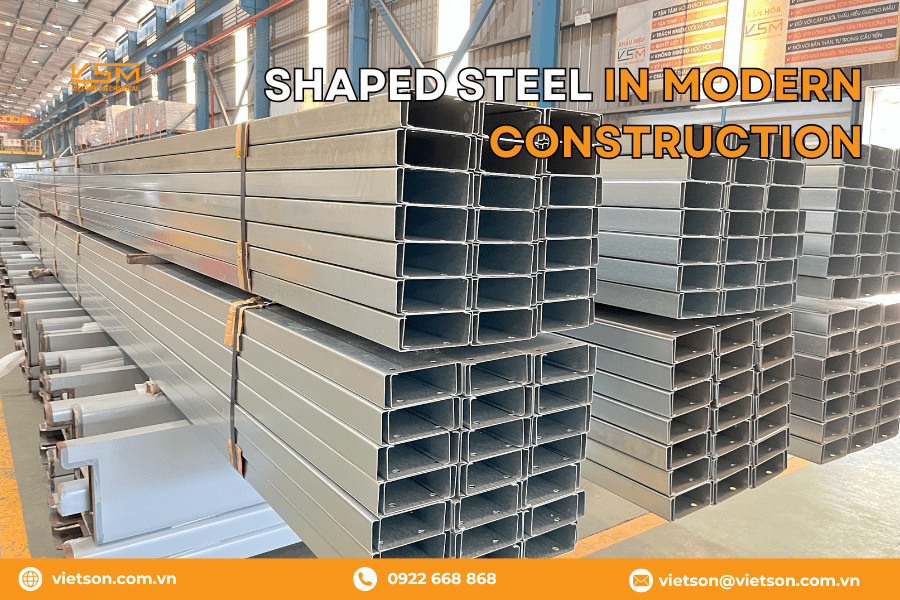

Shaped steel is a type of metal material produced by hot rolling or cold rolling of steel billets in different shapes, such as U-shaped, C-shaped, Z-shaped, etc. Shaped steel has many outstanding advantages such as durability. Highly durable, good load-bearing, easy to process and install, etc. Therefore, shaped steel is widely used in many different fields, from construction, mechanics, energy, shipbuilding, medical equipment economics, furniture,…

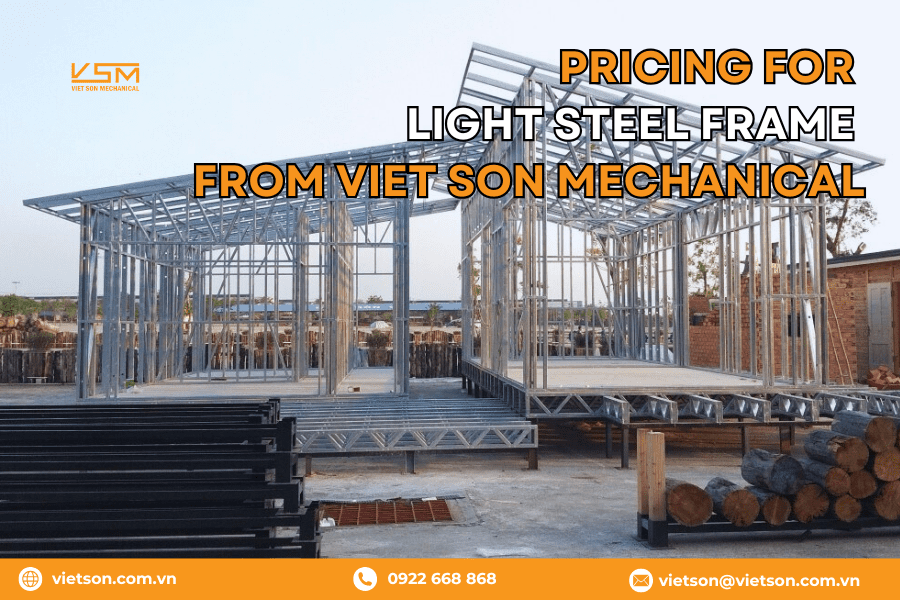

Application in construction: Shaped steel is one of the most important materials in the construction industry. Sectional steel is used to create structures and column frames for buildings, bridges, industrial factories and other construction projects.

Application in mechanical engineering: Shaped steel is also widely used in the mechanical industry. Sectional steel is used to create machine parts, structural frames for industrial machines, and other products in the field. In the mechanical industry, shaped steel is often used to make machine frames, engine frames, gearbox frames, etc. Shaped steel is also used to make machine parts that need high durability and good load-bearing, such as shafts, Gear,…

Applications in energy manufacturing: In the energy industry, steel sections are used in the construction and protection of energy facilities such as power plants, nuclear plants, and energy-related facilities. Sectional steel is used to make column frames, plant frames, cooling tower frames, etc. in power plants. Shaped steel is also used to make reactor frames, protective frames, etc. in nuclear plants.

Application in shipbuilding: In the shipbuilding industry, shaped steel is also used to build ship hulls, seaports and structures related to the transportation of goods at sea. Shaped steel is used to make ship hull frames, deck frames, bridge frames, etc. Shaped steel is also used to make ship parts that need high durability and good load-bearing, such as propeller shafts, rudders, etc.

Application in medical equipment: In some medical applications, shaped steel can be used in the construction of hospitals and other medical facilities, as well as in the production and processing of medical equipment Needs high durability and load capacity. Sectional steel can be used to make hospital frames, hospital bed frames, medical instrument frames, etc. Sectional steel can also be used to make medical equipment parts that need high durability and good load bearing. , such as surgical machine frames, X-ray machine frames,…

Application in furniture: Shaped steel can also be used in the furniture manufacturing industry to create interior products such as tables, chairs, shelves and other interior decorations. Shaped steel can be used to make table frames, chair frames, shelf frames, etc. Shaped steel can also be used to make interior decoration details that need high durability and good load-bearing, such as stair railings. , stair handles,…

Other applications: In addition to the above fields, shaped steel is also used in many other fields depending on specific requirements.

Processing process of rolling metal shaped steel

Step 1: Receive customer requests

The first step in the shaped steel production process is to receive customer requests. Customer requirements include design drawings, technical requirements, quantity of products to be produced, etc.

Step 2: Design

After receiving the customer’s request, the design engineer will use specialized software to design the product. Design software will help engineers determine the size, shape, chemical composition, etc. of the product.

Step 3: Export data

After completing the design, the engineer will export the product data to a file. This file includes drawings, materials list, machine operating data, etc.

Step 4: Production

Based on the exported data, workers will proceed to produce the product. Production of shaped steel is usually carried out by two methods:

Hot rolling: This method uses high temperatures to change the shape of the steel billet. This method is often used to produce large-sized and high-precision steel products.

Cold rolling: This method uses pressure to change the shape of the steel billet at normal temperature. This method is often used to produce shaped steel products with small sizes and lower precision.

Step 5: Packaging and delivery

After production is completed, shaped steel products will be packaged and delivered to customers.

Characteristics and applications of some types of shaped steel at Viet Son Mechanical

UCZ purlins are produced from steel tape, through the rolling process with a specialized purlin machine to become purlin products.

Steel purlins are often used as steel frames and trusses for warehouses, factories, civil works, as steel arms for casting lofts, prefabricated houses, car trunks and other household goods…

Purlins are manufactured from hot-rolled, cold-rolled or hot-dip galvanized steel. Purlins are manufactured with length, size and position of punching holes according to customer design requirements.

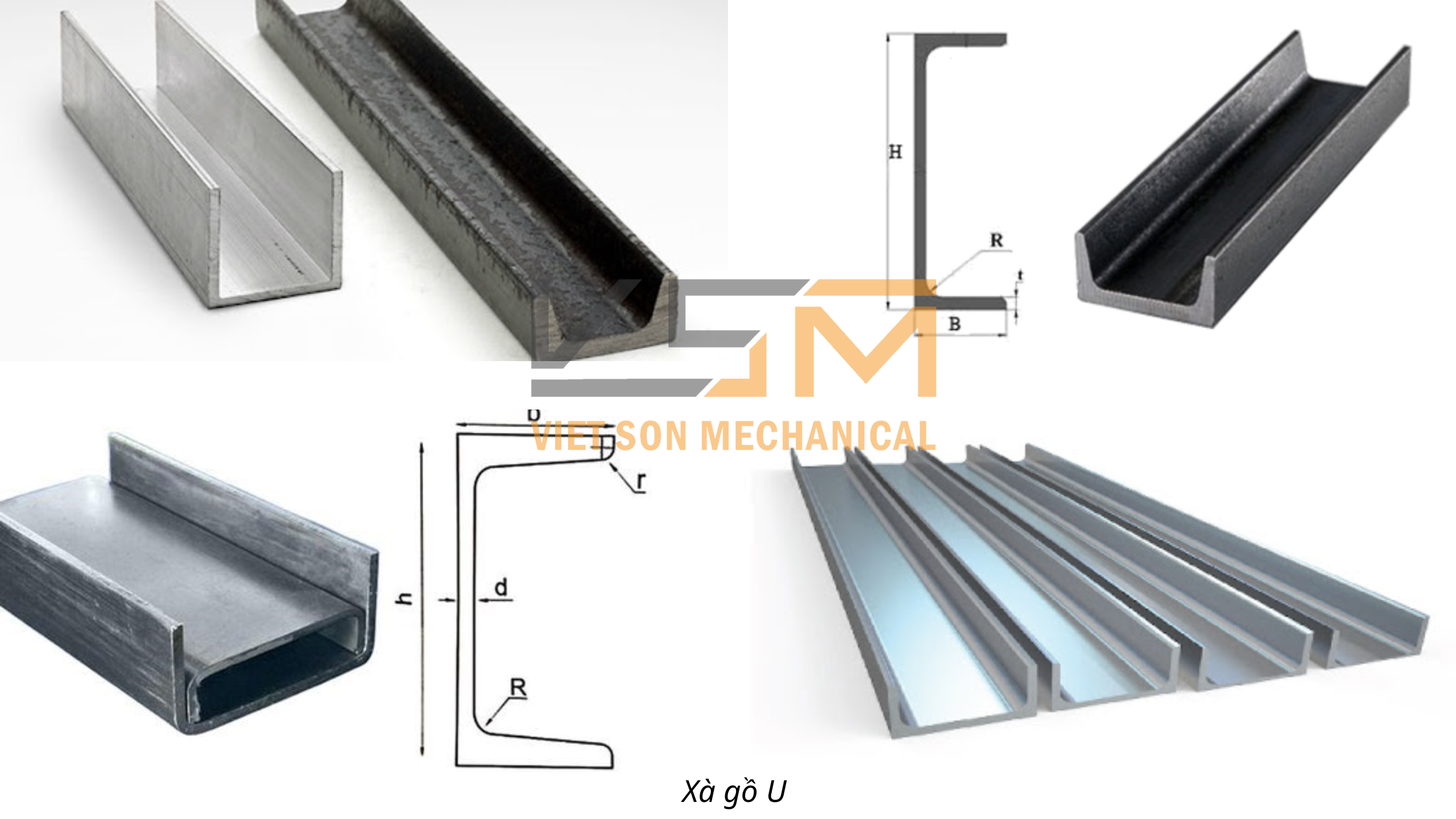

U purlin

- U purlin

Shape and structure

U purlins are shaped like the letter U when viewed from the side, with two parallel vertical edges and one horizontal edge on top.

Simple structure, consisting of 3 main parts: edge, body and ribs.

Material

Black steel: is the most popular material for producing U purlins, with the advantage of high durability and good bearing capacity.

Galvanized steel: has good rust resistance, suitable for projects in harsh environments.

Aluminum: lighter than steel, but lower bearing capacity

Advantage

High bearing capacity: U purlins have good bearing capacity and can withstand large loads.

High durability: U purlins are highly durable and can be used for a long time.

Good rust resistance: U purlins are made from galvanized steel or aluminum with good rust resistance.

Easy to construct: U purlins have a simple structure and are easy to construct and install.

Reasonable price: U purlins have a reasonable price, suitable for many users.

Application

U purlins are used as roof beams, floor beams, and purlins in factories, warehouses, high-rise buildings, etc.

U purlins are also used as frames for partition systems, ceilings, etc.

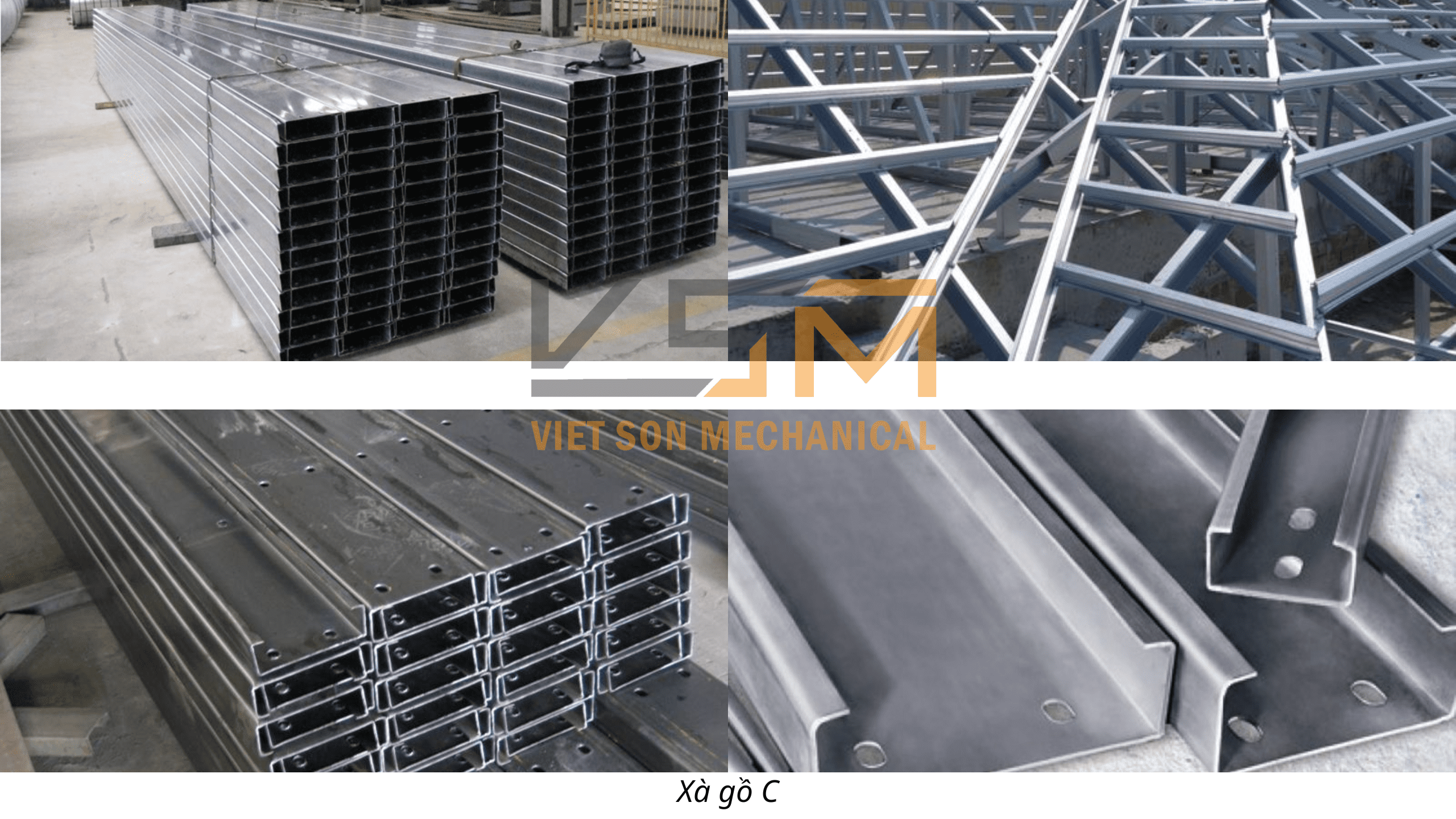

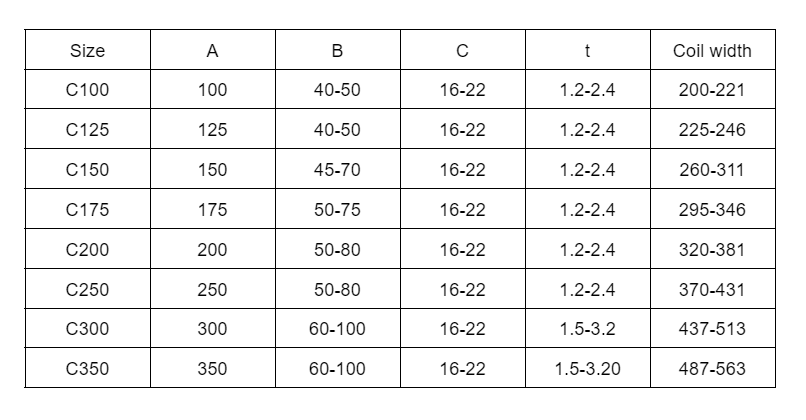

Purlin C

- Purlin C

Shape and structure

C purlins are shaped like the letter C when viewed from the side, with one edge and one body.

Simple structure, consisting of 2 main parts: edge and body.

Material

Black steel: is the most popular material for producing C purlins, with the advantage of high durability and good bearing capacity.

Galvanized steel: has good rust resistance, suitable for projects in harsh environments.

Aluminum: lighter than steel, but lower bearing capacity.

Advantage

High bearing capacity: C purlins have good bearing capacity and can withstand large loads.

High durability: C purlins are highly durable and can be used for a long time.

Good rust resistance: C purlins are made from galvanized steel or aluminum with good rust resistance.

Easy to construct: C purlins have a simple structure and are easy to construct and install.

Reasonable price: C purlin has a reasonable price, suitable for many users.

Application

C purlins are used as roof beams, floor beams, and purlins in factories, warehouses, high-rise buildings, etc.

C purlins are also used as frames for partition systems, ceilings, etc.

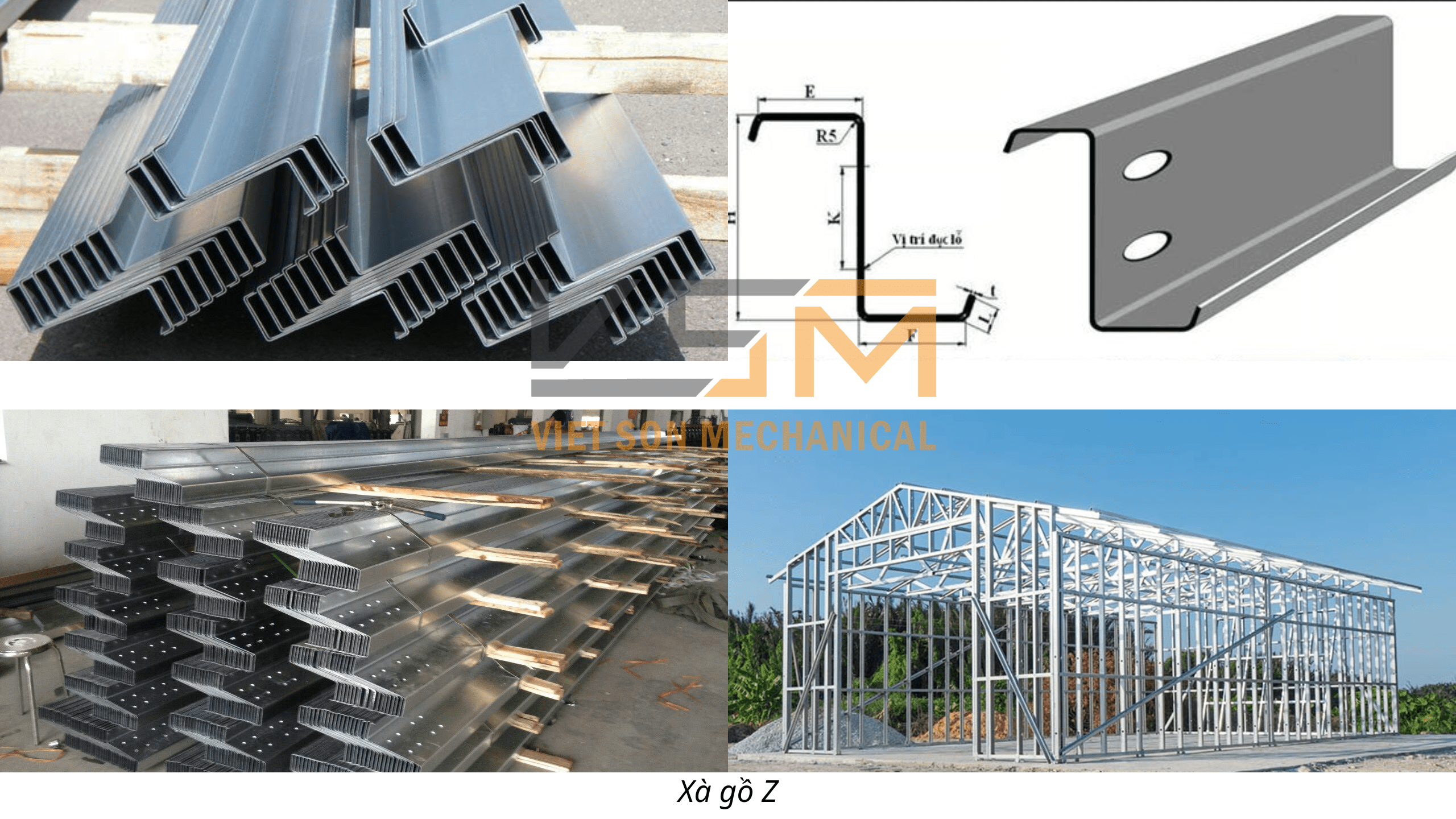

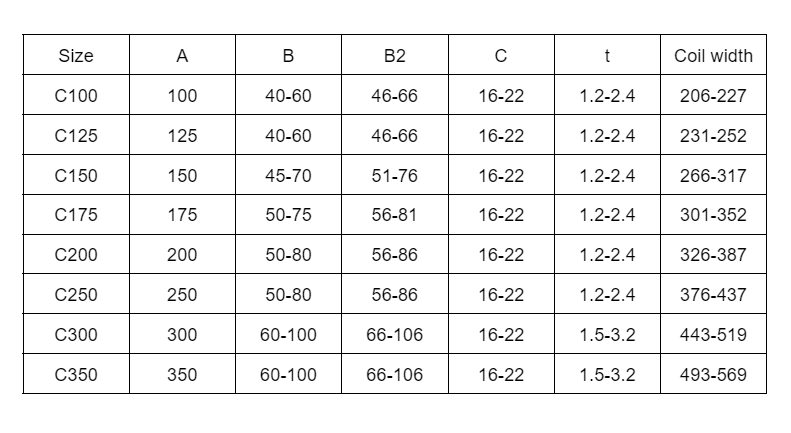

Z purlin

- Z purlin

Shape and structure

Z purlins are shaped like the letter Z when viewed from the side, with two edges and a rib in the middle.

Simple structure, consisting of 3 main parts: edge, ribs and body.

Material

Black steel: is the most popular material for producing Z purlins, with the advantage of high durability and good bearing capacity.

Galvanized steel: has good rust resistance, suitable for projects in harsh environments.

Aluminum: lighter than steel, but lower bearing capacity.

Advantage

High bearing capacity: Z purlins have good bearing capacity and can withstand large loads.

High durability: Z purlins are highly durable and can be used for a long time.

Good rust resistance: Z purlins are made from galvanized steel or aluminum with good rust resistance.

Easy to construct: Z purlin has a simple structure, easy to construct and install.

Reasonable price: Z purlin has a reasonable price, suitable for many users.

Application

Z purlins are used as roof beams, floor beams, and purlins in factories, warehouses, etc.

Z purlins are also used as frames for partition systems, ceilings, etc.

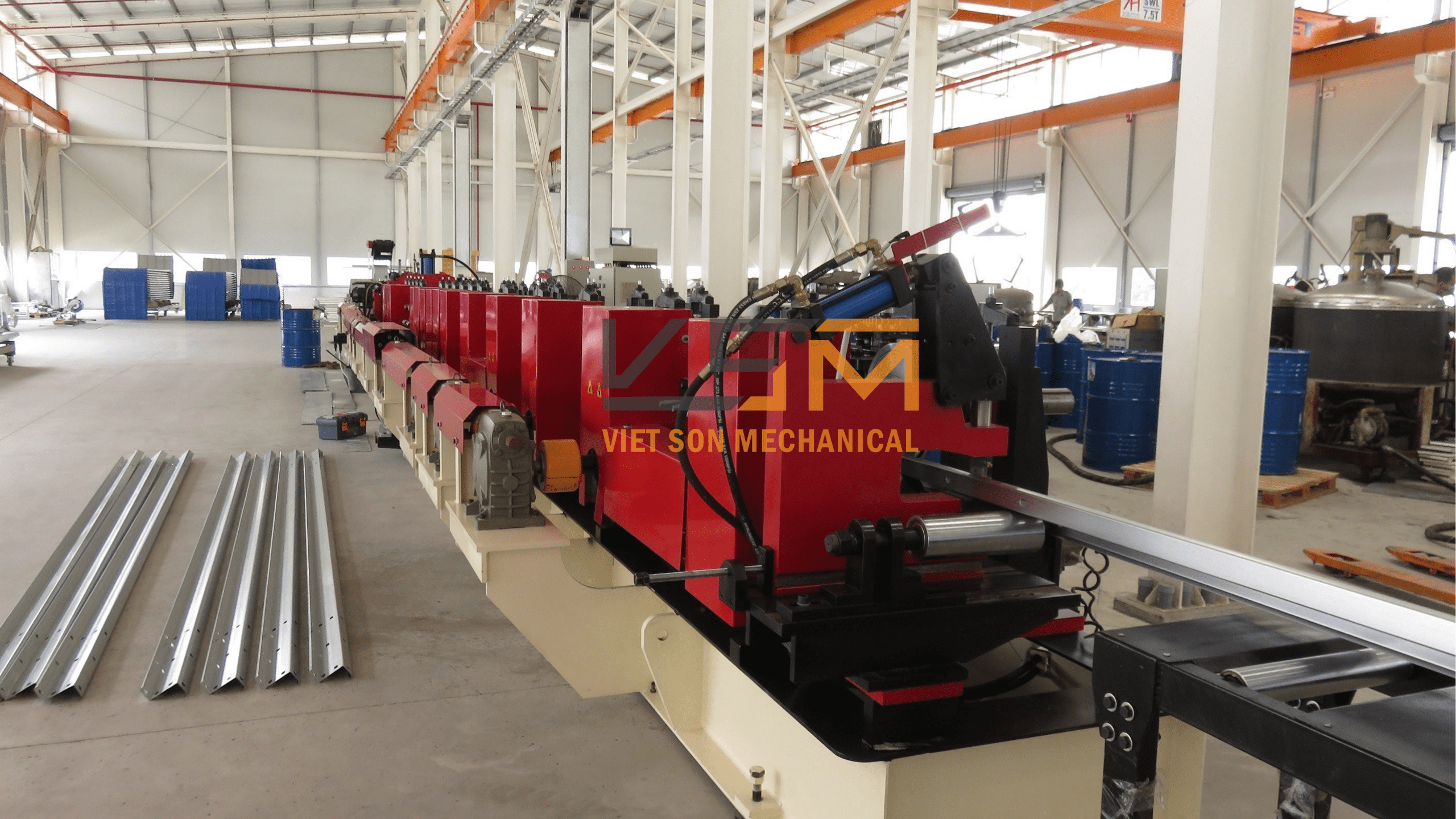

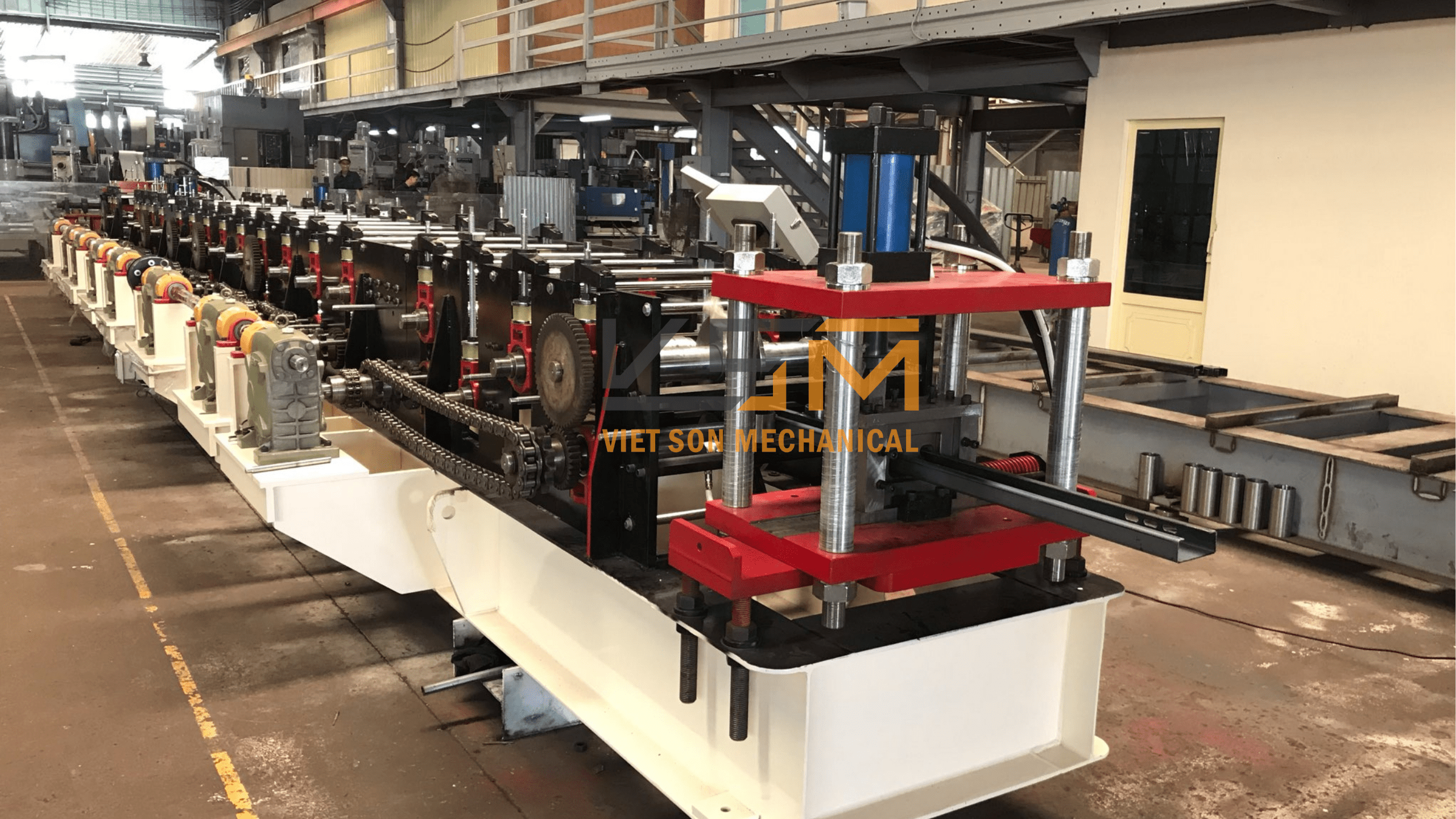

Modern technology and equipment

- Z purlin rolling machine

- C purlin rolling machine

- Purlin rolling machine

Viet Son Mechanical – Prestigious and quality rolled steel processing unit

Viet Son Mechanical is a reputable and quality rolled steel processing unit for the following reasons:

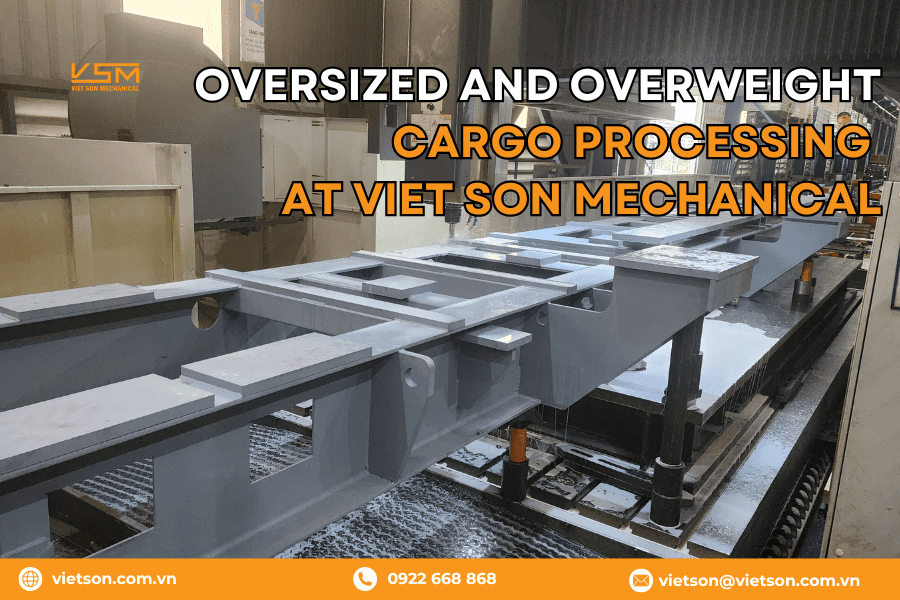

Modern machinery and equipment: Viet Son Mechanical is equipped with modern machinery and equipment to perform shaped steel processing effectively and with quality. This can ensure that the final product meets specific technical requirements and standards.

High precision: Using advanced machinery and technology, Viet Son Mechanical has the ability to work with high precision, helping the final product have accurate dimensions and characteristics.

Meet large output: Viet Son Mechanical has the ability to meet large output, this is especially important if you have a large order or need to mass produce products.

Fully certified materials: Viet Son Mechanical is capable of providing quality certified steel materials, ensuring that your products comply with safety and quality standards.

Guaranteed on schedule: Viet Son Mechanical can commit to the project’s schedule and ensure that your order will be completed on time, this is especially important in construction and industrial production. .

Prestige and quality: Viet Son Mechanical has a reputation in the metal and steel processing industry, and they are recognized for the quality of their products and services.

Above is information about shaped rolled steel processing of Viet Son Mechanical. If you have a need for processing or need to find a unit price for processing shaped steel, please contact Viet Son immediately for support!

Above is information about shaped rolled steel processing of Viet Son Mechanical. If you have a need for processing or need to find a unit price for processing shaped steel, please contact Viet Son immediately for support!

► Contact for processing: 0922 668 868 (Zalo – Viber – WhatsApp)

► Address: Lot C2-7, Road N7, Tan Phu Trung Industrial Park, Tan Phu Trung Commune, Cu Chi District, City. HCM

► Website: https://vietson.com.vn/

► Email: [email protected]

► Facebook: www.facebook.com/GiaCongVietson/

► Youtube: https://www.youtube.com/channel/UC_n7V8NDRtO75pSOUOMiQ8w