Light steel frame construction is a game-changer in modern building practices. Using lightweight steel framing systems, this innovative method offers strength, cost-effectiveness, and eco-friendliness. In this article, we explore the key features and benefits of light steel frame construction, highlighting its efficiency, design flexibility, and sustainable nature. Join us as we dive into the world of light steel frame construction and discover its transformative impact on the construction industry.

What is lightweight steel frame?

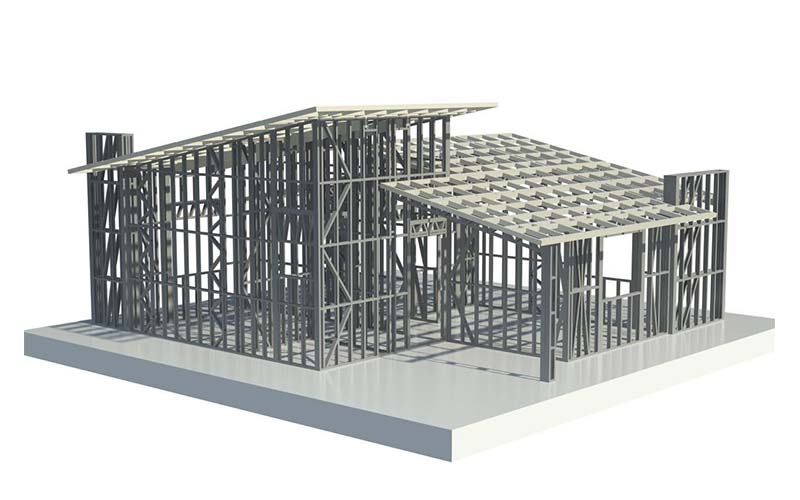

A lightweight steel frame refers to a structural system constructed using steel members that are relatively lightweight compared to traditional steel structures. It involves the use of cold-formed steel sections, which are manufactured by bending or rolling thin sheets of steel into desired shapes and profiles.

The lightweight steel frame construction technique is often used in residential, commercial, and industrial buildings.

Features of the Light Steel Frame

The features of a light steel frame construction include:

- Lightweight: Light steel frames are significantly lighter compared to traditional construction materials such as concrete or masonry. This characteristic allows for easier transportation, handling, and assembly on-site.

- High strength: Despite their lightweight nature, light steel frames possess high strength and load-bearing capacity. The use of cold-formed steel sections with precise engineering ensures structural stability and durability.

- Design flexibility: Light steel frames offer design flexibility, allowing for versatile and creative architectural designs. The steel sections can be easily shaped and customized to meet specific design requirements, enabling architects to create unique and complex structures.

- Precision manufacturing: Light steel frames are typically prefabricated off-site using advanced manufacturing techniques. This precision manufacturing ensures consistent quality and accurate dimensions, leading to faster construction and minimal on-site adjustments.

- Speed of construction: The prefabrication process, along with the lightweight and easy assembly of light steel frames, enables faster construction compared to traditional methods. This can lead to reduced labor costs and quicker project completion.

- Sustainable and recyclable: Steel is a highly sustainable material as it is 100% recyclable. Light steel frames promote sustainability by using recycled steel and minimizing waste during the construction process. Additionally, the lightweight nature of these frames requires less energy for transportation and reduces the carbon footprint.

- Fire resistance: Light steel frames are designed to meet stringent fire safety standards. Steel is inherently fire-resistant and does not contribute to the spread of flames, making light steel frame constructions a safer choice.

- Termite and rot resistance: Steel is not susceptible to termites, pests, or rot, which can be a concern with other construction materials such as wood. Light steel frames provide a durable and long-lasting solution that is resistant to biological deterioration.

- Reduced foundation requirements: Due to their lightweight nature, light steel frames exert less load on the foundation compared to heavier construction materials. This can result in cost savings in terms of foundation design and construction.

Overall, light steel frame construction offers a range of benefits, including strength, design flexibility, sustainability, and speed of construction. These features make it an attractive option for various building types, including residential, commercial, and industrial structures.

What are the advantages of lightweight steel framing?

Cost-effective

Lightweight steel framing offers cost advantages in multiple aspects. The prefabrication process allows for efficient material usage, minimizing waste and reducing costs. Additionally, the lightweight nature of the frames simplifies transportation and installation, leading to potential savings in labor and equipment expenses.

Fast Build Times

One of the key advantages of lightweight steel framing is its ability to significantly reduce construction time. The prefabricated steel components are manufactured off-site, allowing for parallel work processes. This concurrent construction approach, combined with the ease of assembly, can result in accelerated project schedules and early occupancy, which is especially beneficial for commercial or residential developments.

Durability

Lightweight steel frames are highly durable and resilient. Steel is resistant to pests, such as termites, and does not rot or decay. It can withstand extreme weather conditions, including high winds and seismic events. The structural integrity of lightweight steel frames remains intact over time, reducing the need for frequent repairs or maintenance.

Eco-friendliness

Lightweight steel framing is considered an eco-friendly construction option. Steel is a recyclable material, meaning that it can be reused without losing its properties. This promotes sustainable practices by reducing the demand for new steel production and minimizing waste. Additionally, the energy efficiency of steel-framed buildings can be enhanced through the incorporation of insulation materials, resulting in reduced energy consumption and lower environmental impact.

What to Take Away

Lightweight steel framing offers numerous advantages, making it an attractive option for various construction projects. Its cost-effectiveness, fast build times, durability, and eco-friendliness contribute to its popularity in the industry. By utilizing lightweight steel frames, builders can achieve efficient, sustainable, and resilient structures that meet the needs of modern construction practices.

What is the disadvantage of light steel frame?

While light steel framing has many advantages, there are a few potential disadvantages to consider:

- Initial Cost: Light steel framing systems may have a higher initial cost compared to traditional construction methods like wood framing. The cost of steel materials, as well as the specialized engineering and fabrication processes involved, can contribute to higher upfront expenses. However, it’s important to consider the long-term benefits and potential cost savings in terms of durability, maintenance, and energy efficiency.

- Limited Span Length: Light steel frames typically have a smaller span length compared to heavier construction materials like concrete or steel beams. This limitation may require additional structural supports or intermediate load-bearing walls, which can impact the interior layout and design flexibility of the building.

- Acoustic Performance: Steel is a relatively conductive material, which means that it can transmit sound more effectively than other materials like wood or concrete. Without proper acoustic insulation measures, light steel frame constructions may have reduced soundproofing capabilities. However, this can be addressed by incorporating sound-absorbing materials or insulation layers in the design.

- Thermal Conductivity: Steel has higher thermal conductivity compared to materials like wood or insulation materials. If not properly insulated, light steel frames may allow more heat transfer, potentially impacting the energy efficiency of the building. However, this can be mitigated by incorporating effective thermal insulation systems, such as insulation panels or spray foam insulation.

- Fire Protection: While steel is inherently fire-resistant, it can lose strength under high temperatures. Therefore, fire protection measures, such as fire-resistant coatings or fire-rated gypsum boards, need to be applied to the steel framing to ensure adequate fire safety. Proper fire engineering and adherence to building codes and regulations can address this concern effectively.

It’s worth noting that many of these disadvantages can be overcome or mitigated through proper design, construction techniques, and the use of appropriate materials. Working with experienced professionals who have expertise in lightweight steel frame construction can help address these potential drawbacks and ensure a successful and efficient construction project

What is LSF in construction?

LSF stands for Light Steel Frame, and it refers to a construction method that utilizes lightweight steel framing systems to build structures. LSF construction involves the use of cold-formed steel sections, typically made from galvanized steel, which are lightweight yet strong.

In LSF construction, the steel framing members are fabricated off-site and then transported to the construction site for assembly. These steel sections are often in the form of studs, tracks, and joists, which are interconnected to create a structural framework. The steel members are typically lightweight and easily handled, allowing for faster and more efficient construction processes.

LSF construction offers several advantages, including cost-effectiveness, design flexibility, speed of construction, durability, and eco-friendliness. It is commonly used in residential, commercial, and industrial buildings, ranging from single-family homes and apartments to schools, offices, and warehouses.

LSF construction techniques have gained popularity due to their ability to deliver structurally sound and high-quality buildings in a shorter time frame compared to traditional construction methods. The use of lightweight steel framing systems enables efficient prefabrication, ease of transportation, and swift on-site assembly, leading to faster project completion and reduced labor costs.

Overall, LSF construction has become a preferred choice for many builders and developers, offering a reliable and efficient alternative to conventional construction methods.

In conclusion, LSF (Light Steel Frame) construction is a cost-effective, efficient, and durable method of building using lightweight steel framing systems. It offers design flexibility, fast build times, and eco-friendliness. While there are some considerations such as initial cost and acoustic performance, LSF construction provides numerous advantages that make it a popular choice in the construction industry.